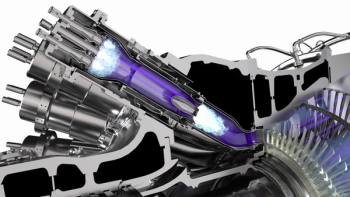

Bearings that combat pivot wear and vibrations

Waukesha Bearings (WB) offers tilting pad thrust, journal, combination and fixed profile bearings, used in pumps, motors, compressors, turbines, generators and gearboxes. Examples include Maxalign bearings that reduce power loss and handle misalignment in large shaft turbomachinery, Flexure Pivot bearings that eliminate pivot wear, pad flutter and tolerance stack up, and MLSF bearings that improve stability and lifespan when compared to conventional floating ring bearings.

Advanced material bearings

In addition, WB supplies housed horizontal and vertical bearing assemblies that include design options such as cooling, electrical insulation, hydrostatic jacking, self-contained ring or disc lubrication, and instrumentation, for use in pumps, motors and generators in applications such as nuclear power stations and air-cooled units for LNG pumps. The company also employs advanced material bearings, such as Hiperax and Hidrax to withstand high temperatures, high loads and abrasive materials, as well as axial and radial magnetic bearings, RDS auxiliary bearings, position sensors and control systems that increase reliability and availability, and reduce the need for on-site maintenance.

Barry Blair, Chief Engineer for Fluid Film Bearings at WB said, “We are seeing more partnerships between OEMs, end users and bearing suppliers, which allow each expert to share their knowledge for improved technical collaboration and testing validation. There is higher market demand for directed lubrication and the use of synthetic oils and other lubricant options. We are also noticing lower power losses, lower oil flow rates and smaller oil tanks.”

Pad-pivot-retainer design

For small diameter shafts operating at high speeds and high loads, Flexure Pivot bearings address problems such as pivot wear and vibration increase. They have an integral pad-pivot-retainer design, manufactured as one piece. WB’s ISFD technology for radial bearings ups the damping capability to combat sub-synchronous vibrations.

Additionally, WB is a major presence in AMBs. Its compact Zephyr controller provides the opportunity to fit a redundant controller configuration in the same space envelope as older non-redundant controllers. These Waukesha magnetic bearing controllers can measure and process all data required to commission the bearing system. This eliminates the need for ancillary equipment for the commissioning process, such as signal analyzers. AMB controllers can now be placed 500 meters away from the machine, said Richard Shultz, Chief Engineer for Magnetic bearings at WB.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.