Compressors

Latest News

MIRATECH Acquires Advanced Catalyst Systems, Expands Manufacturing Capacity

Glenfarne Agrees to Supply Natural Gas, Build Power Plant for Donlin Gold Mine

Latest Videos

Shorts

Podcasts

More News

The 40,000-cubic-meter vessel will support a government-backed demonstration aimed at commercializing the global transport of liquefied hydrogen by 2030.

The MK2 project will convert Golar’s LNG tanker—Fuji LNG—into a floating LNG vessel with an expected annual production capacity of 3.5 million tons.

Digital tools, AI, and predictive maintenance are reshaping turbomachinery and driving gains in reliability, efficiency, and long-term asset performance in 2025.

The company will integrate EthosEnergy’s TurboCare team, technical data, and intellectual property to support a broad range of OEM technologies.

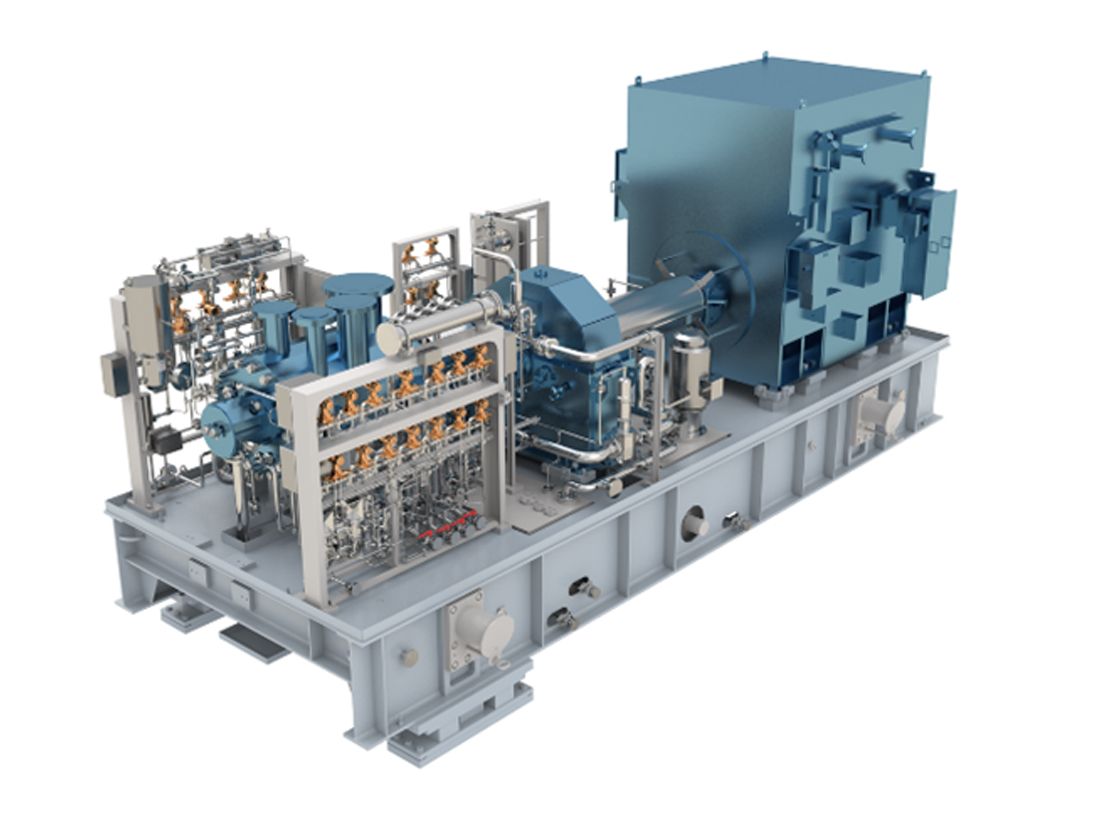

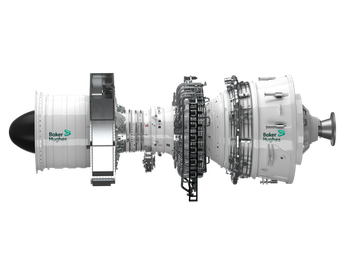

In addition to delivering centrifugal compressors and LM9000 aeroderivative gas turbines, the full scope includes commissioning services, spares and warranties, and full string tests.

Increasing pipeline capacity will satisfy demand growth in the Desert Southwest region, which includes initiatives to retire and/or convert coal-fired plants to natural gas usage.

The major milestones for Belgium’s electricity supply include a combined-cycle gas turbine plant, a battery energy storage system, and the Coo pumped-storage plant.

KOHO and Svanehøj previously collaborated on numerous high-profile shipbuilding projects, such as the Northern Lights LCO2 carriers and Höegh Autoliners’ Aurora-class design.

Previously, the undisclosed operator shifted its strategy from equipment availability to long-term reliability and enlisted John Crane to solve sealing inconsistency issues at a flagship refinery.

Following capture with the Advanced KM CDR Process, the CO2 will be transported via pipeline for permanent sequestration in depleted gas fields beneath Liverpool Bay.

Many turbomachinery diagrams are outdated and recommend axial machines over centrifugals, but modern technological advancements must be considered for industrial applications.

Although Malaysia’s decarbonization efforts focus on hydropower and solar, Everllence’s gas engines can balance fluctuating renewable input with short response times and high efficiency.

Among other causal factors, stress concentrations accumulate in areas with sharp edges, so filleting and chamfering is required to enable the smooth flow of stress streamlines.

By 2030, the Kawasaki LH2 Terminal will enter operation alongside a newly constructed liquefied hydrogen carrier, advancing Japan’s effort to establish a hydrogen supply chain.

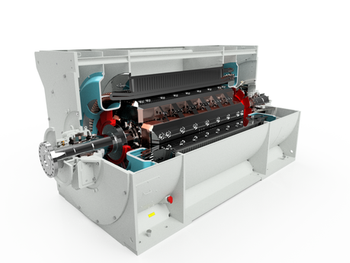

The 2025 Turbomachinery & Pump Symposia covered hydrogen compressor testing, new gas seal technology, various pumps for ammonia and supercritical operations, and more.

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

Dynamis Power Solutions will package multiple LM9000 gas turbines as a mobile solution, providing increased versatility for large-scale power consumers in the oil and gas space.

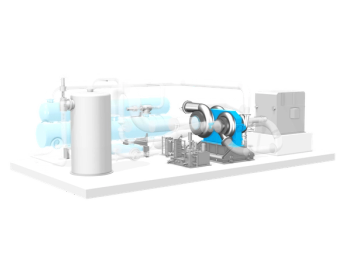

The magnetic bearing technology reinforces an oil-free design, eliminating the need for a lubrication oil system and preventing wear on sliding parts.

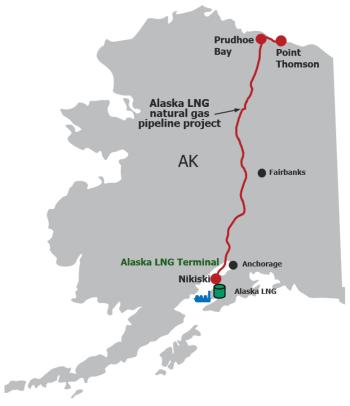

Since Glenfarne became lead developer in March, Alaska LNG has secured commitments for 11 MTPA of LNG from buyers in Japan, Taiwan, South Korea, and Thailand.

Under the additional contract for Train 5, Baker Hughes will deliver two Frame-7 gas turbines and six centrifugal compressors to support approximately 6 MTPA at the facility.

In addition to installing the world’s largest steam heat pump at Kendall Station, Everllence will include a dynamic process simulation and digital twin of the system.

When using gear units within turbomachinery trains, operators should consider wear and degradation, torsional problems, lubrication, and more.

The Blue Point Number One Ammonia Project will produce blue ammonia via autothermal reforming while capturing up to 2.3 million metric tons of CO2 per year.

The 2026 Handbook includes a comprehensive outlook of the U.S. power industry and gas turbine market, as well as an industry-wide directory and specifications listings.

The Turbomachinery News Network, for the week of October 20, 2025, covers news from NextDecade, Everllence, Doosan Enerbility, ExxonMobil, and Capstone Green Energy.