Auxiliaries & Components

Latest News

Latest Videos

Shorts

Podcasts

More News

The company will integrate EthosEnergy’s TurboCare team, technical data, and intellectual property to support a broad range of OEM technologies.

The Qatar Facility E Independent Water and Power Production facility includes a 2,400-MW gas-fired, combined-cycle power plant approximately 10 km southeast of Doha.

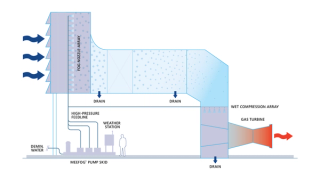

The wet gas scrubbing system features high SO2-removal efficiency, low-pressure operation, reduced energy consumption, and accommodates site layouts with customizable designs.

Beyond supplying power for on-board electrical systems, the mtu Series 4000M35S power generators can secure the propulsion system during emergency scenarios.

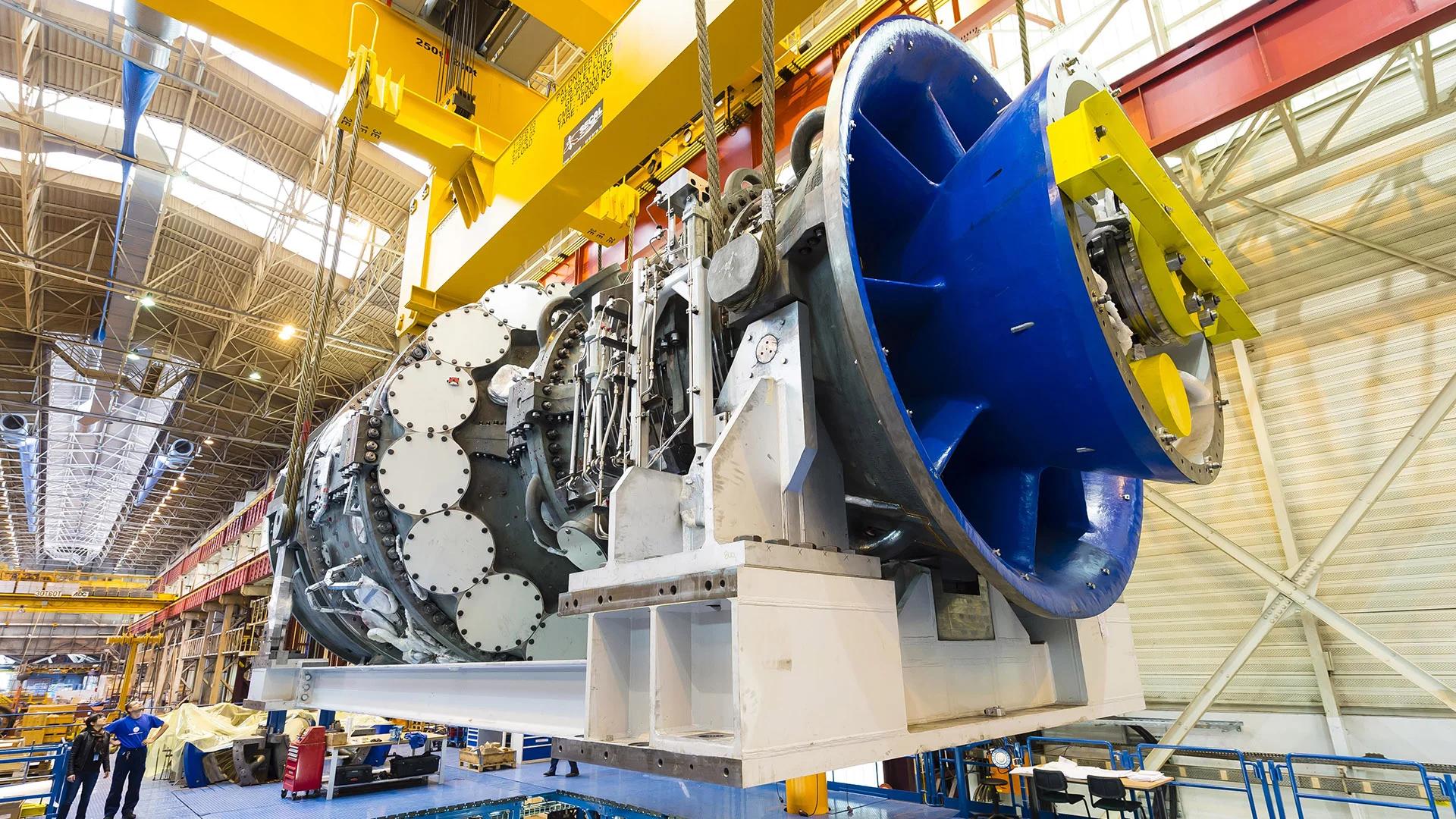

The Superpower gas turbine deploys extreme-temperature technology to maintain generation capacity—without water—in hot, arid, and challenging environmental conditions.

The electrical upgrade will increase oxygen capacity by 10% and immediately reduce CO2 emissions by 224,000 tons per year, furthering China’s industrial decarbonization goals.

The environmental product declarations tracked data on resource consumption, emissions, waste generation, and recyclability for the mtu Series 4000 DS2500 and 1600 systems.

KOHO and Svanehøj previously collaborated on numerous high-profile shipbuilding projects, such as the Northern Lights LCO2 carriers and Höegh Autoliners’ Aurora-class design.

The partners will pursue aging power projects across Central Asia, Africa, and Southeast Asia, executing plant performance improvements and rehabilitation work.

Previously, the undisclosed operator shifted its strategy from equipment availability to long-term reliability and enlisted John Crane to solve sealing inconsistency issues at a flagship refinery.

Following capture with the Advanced KM CDR Process, the CO2 will be transported via pipeline for permanent sequestration in depleted gas fields beneath Liverpool Bay.

The mtu Series 4000 power generator is a low-carbon solution for data centers, allowing users to quickly generate up to 2.8 MW of electricity while filtering CO2 from exhaust gases.

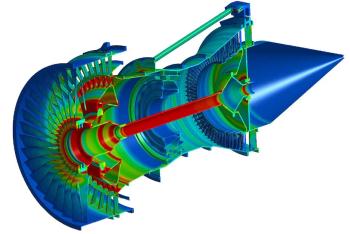

Many turbomachinery diagrams are outdated and recommend axial machines over centrifugals, but modern technological advancements must be considered for industrial applications.

Among other causal factors, stress concentrations accumulate in areas with sharp edges, so filleting and chamfering is required to enable the smooth flow of stress streamlines.

By 2030, the Kawasaki LH2 Terminal will enter operation alongside a newly constructed liquefied hydrogen carrier, advancing Japan’s effort to establish a hydrogen supply chain.

In comparison to traditional supercomputers, quantum computing offers a notable speed advantage and may accelerate simulation time exponentially.

The 2025 Turbomachinery & Pump Symposia covered hydrogen compressor testing, new gas seal technology, various pumps for ammonia and supercritical operations, and more.

On the modernization side, Doosan Skoda will deliver a turnkey solution covering the design, manufacturing, civil works, installation, and commissioning of the Opatovice Power Plant.

The precision and efficiency of laser-based welding systems can address key industry challenges, such as labor shortages, operational downtime, and quality consistency.

Mechanical design decisions—ranging from stress management to natural frequency tuning—play a critical role in the reliability of steam turbines across demanding mechanical drive applications.

Combining Overwatch’s SIDE Platform with Idemitsu’s natural gas supply will help meet rising demand from hyperscalers, GPU-cloud providers, and investors seeking to build AI computing.

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

Separate from liquid ammonia operation, the ME-LGIA also sends real-time engine and operational data to Everllence shore-based monitoring to improve performance.

In 2024, the Industrial Process manufacturing facility secured $160 million in orders and is targeting over $300 million in annual orders by 2030.

The industrial-scale ammonia cracking unit utilizes key enhancements across critical areas, including process safety, material testing, ammonia combustion, molecule separation, and more.