Maintenance & Repair

Latest News

Rotating Machinery Services Obtains TurboCare to Enhance Turbine, Compressor Services

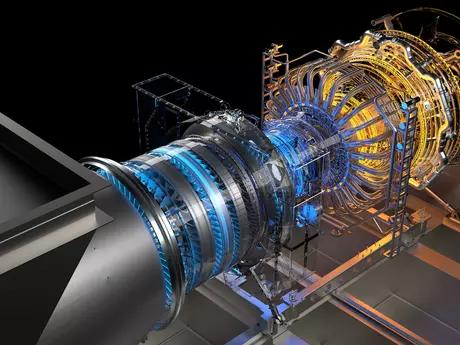

Baker Hughes’ Equipment Drives Liquefaction at Commonwealth LNG Export Facility

Latest Videos

Shorts

Podcasts

More News

Beyond supplying power for on-board electrical systems, the mtu Series 4000M35S power generators can secure the propulsion system during emergency scenarios.

The major milestones for Belgium’s electricity supply include a combined-cycle gas turbine plant, a battery energy storage system, and the Coo pumped-storage plant.

The environmental product declarations tracked data on resource consumption, emissions, waste generation, and recyclability for the mtu Series 4000 DS2500 and 1600 systems.

The partners will pursue aging power projects across Central Asia, Africa, and Southeast Asia, executing plant performance improvements and rehabilitation work.

Previously, the undisclosed operator shifted its strategy from equipment availability to long-term reliability and enlisted John Crane to solve sealing inconsistency issues at a flagship refinery.

The mtu Series 4000 power generator is a low-carbon solution for data centers, allowing users to quickly generate up to 2.8 MW of electricity while filtering CO2 from exhaust gases.

Many turbomachinery diagrams are outdated and recommend axial machines over centrifugals, but modern technological advancements must be considered for industrial applications.

Although Malaysia’s decarbonization efforts focus on hydropower and solar, Everllence’s gas engines can balance fluctuating renewable input with short response times and high efficiency.

Among other causal factors, stress concentrations accumulate in areas with sharp edges, so filleting and chamfering is required to enable the smooth flow of stress streamlines.

The 2025 Turbomachinery & Pump Symposia covered hydrogen compressor testing, new gas seal technology, various pumps for ammonia and supercritical operations, and more.

On the modernization side, Doosan Skoda will deliver a turnkey solution covering the design, manufacturing, civil works, installation, and commissioning of the Opatovice Power Plant.

The precision and efficiency of laser-based welding systems can address key industry challenges, such as labor shortages, operational downtime, and quality consistency.

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

Kozienice is transitioning away from coal-fired power generation, instead using natural gas to generate up to 60% less emissions compared to fossil-fired plants of a similar size.

The magnetic bearing technology reinforces an oil-free design, eliminating the need for a lubrication oil system and preventing wear on sliding parts.

Performance Plus combines data-driven monitoring, expert consultancy, and hands-on training to help turbomachinery users reduce downtime and boost reliability and long-term resilience.

Following over 250,000 hours of testing, the Jenbacher NX Oil 40 demonstrated significantly reduced soot formation, lower particle counts, and improved dispersion over oil drain intervals.

With Antea’s mechanical integrity capabilities, Cordant will link inspection data to asset strategy and performance to optimize maintenance and reduce OPEX costs.

The company will service and maintain multiple units at the Taishan nuclear power plant, in addition to supplying a steam turbine, generator, and controls for the Natrium Wyoming plant.

The new update improves volute modeling with enhanced 3D models and tongue geometries, in addition to expanded leakage path capabilities with a secondary network solver.

When using gear units within turbomachinery trains, operators should consider wear and degradation, torsional problems, lubrication, and more.

By 2030, the Jafurah gas field may produce up to 630,000 barrels of natural gas liquids and condensates, in addition to over 420 million cubic feet of ethane per day.

Since installation, the Fadhili Gas Plant has demonstrated a 10 – 15% reduction in amine and steam usage and an approximately 5% reduction in power usage.

The company’s coiled-tube drilling operations include its CoilTrak bottomhole assembly system and enhanced reservoir analysis driven by the GaffneyCline energy advisory.

The 2026 Handbook includes a comprehensive outlook of the U.S. power industry and gas turbine market, as well as an industry-wide directory and specifications listings.