GE completes world’s first DLN1.0+ with ultra low NOx combustion

GE has successfully completed the world’s first installation of its DLN1.0+ with Ultra Low NOx combustion upgrade on nine GE 9E gas turbines at five power generation enterprises (Shenzhen Nanshan Power Corporation, Shenzhen New Power Corporation, Shenzhen Datang Baochang Gas Power Generation Co. Ltd., Shenzhen Yuhu Power Co. Ltd., and CNOOC Shenzhen Power Co. Ltd.) in Shenzhen. GE unveiled the announcement during the “Shenzhen Blue Sky” DLN1.0+ Retrofit Project Completion Celebration Event it co-hosted with Shenzhen Municipal Ecology and Environment Bureau and Shenzhen Nanshan Power Corporation. More than 100 power plant operators attended the event.

This upgrade reduces NOx emissions from 50mg/m3 (about 25ppm) to 15mg/m3 (about 7.5ppm), thus contributing to Shenzhen Municipal Government’s “Blue Sky” initiative. As part of the initiative, all gas-fired power plants in the city are required to lower its emissions below 15mg/m³ in six months. NOx is a contributor to ground level ozone and reductions in emissions helps improve air quality and public health by making it easier to breathe. Power plants that fail to comply with these requirements will be taken offline.

Completed on time, the project mobilized more than 200 experts from China and around the world for factory repairs to meet specific timeframe requirements and exceeded performance expectations. This milestone serves as a model for plant operators that are operating more mature gas turbine fleets in China and around the globe.

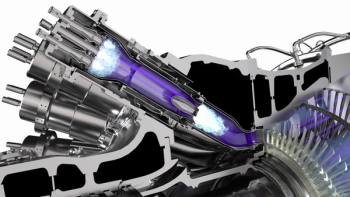

NOx emissions produced in the combustion system increase with the temperature of the flame. A flame with a lower temperature will produce less NOx, and the key is to be able to mix air and fuel together prior to burning. GE’s DLN 1.0+ with Ultra Low NOx upgrade is an improved combustion system for the DLN 1.0 that can reduce NOx down to 5 ppm.

The new configuration includes:

- more robust materials and improved thermal barrier coatings to extend maintenance interval and parts life;

- new combustion hardware - fuel nozzle, liner and transition piece, improving the mixing of air with fuel and enhancing the hot gas temperature profile to achieve industry leading emissionss;

- combustion dynamics monitoring system and improved controls system using “Corrected Parameter Control (CPC)”, an advanced controls feature using real time information, such as ambient humidity, ambient temperature, inlet and exhaust pressure losses to adjust the fuel splits between the primary and secondary fuel circuit, and maintain the emissions below the target.

In addition, the upgrade allows the units to accept fuels with larger Wobbe index fluctuations, expanding gas source choices and helping the units to operate flexibly. The upgrade can potentially extend combustion system maintenance intervals to 32,000 hours or 1,300 starts and stops (equivalent to four consecutive years of stable operation), reduce maintenance costs, increase operational flexibility, and extend the life span of related equipment.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.