How steam turbine protection system works

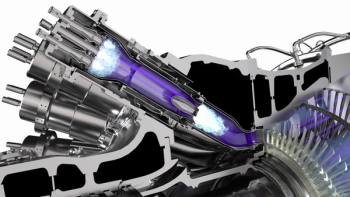

The function of the steam turbine protection system is often confused with the control system, but in fact the two systems are entirely separate. The protection system operates only when any of the control system set point parameters are exceeded, and the steam turbine will be damaged if it continues to operate.

A multi-valve, multi-stage turbine protection system incorporates a mechanical overspeed device (trip pin) to shut down the turbine on overspeed (10 percent above maximum continuous speed).

The protection system monitors steam turbine total train parameters and ensures safety and reliability by the following action:

Start-up (optional) provides a safe, reliable fully automatic start-up and will shut down the turbine on any abnormality

Manual shutdown

Trip valve exerciser allows trip valve stem movement to be confirmed during operation without shutdown

Rotor overspeed monitors turbine rotor speed and will shutdown turbine when maximum allowable speed (trip speed) is attained

Excessive process variable signal monitors all train process variables and will shutdown turbine when maximum value is exceeded

Centrifugal force resulting from high shaft speed will force the trip lever, which will allow the spring loaded handle to move inward. When this occurs, the port in the handle stem will allow the control oil pressure to drain and drop to zero. The high energy spring in the trip and throttle valve, normally opposed by the control oil pressure will close suddenly (less than one second). In this system there are two other means of tripping the turbine (reducing control oil pressure to zero) – manually pushing spring loaded handle and solenoid valve opening.

The solenoid valve will open on command when any trip parameter set point is exceeded. Solenoid valves are designed to be normally energized to close. In recent years, the industry has required parallel and series arrangements of solenoid valves to ensure increased steam turbine train reliability. Today, most speed trip systems incorporate magnetic speed input signals and two out of three voting for increased reliability. The devices that trip the turbine internally directly reduce the control oil pressure, causing a trip valve closure without the need of a solenoid valve (external trip method).

Two popular types of steam turbine shut off valves are available and both use a high spring force, opposed by control oil pressure during normal operation, to close the valve rapidly on loss of control oil pressure.

It is important to note that the trip valve will only close if the spring has sufficient force to overcome valve stem friction. Steam system solid build up, which increases with system pressure (when steam systems are not properly maintained), can prevent the trip valve from closing.

To ensure that the trip valve stem is free to move, all trip valves should be manually exercised on-line. The recommended frequency is once per month for High Pressure (40 bar) steam systems and daily for very high pressure (1000 bar +) steam systems. All the turbine trip valves should be provided with manual exercisers to allow this feature.

It can be hard to maintain VHP (very high pressure) steam systems, and to prevent contaminants (calcium, silica) from forming inside the turbine. Trip valve packing is essentially a filter that will trap any contaminants between the trip valve and the packing which can prevent the trip valve from closing.

Failure of the trip valve to close on command can cause catastrophic machine failure and expose personnel to safety issues. Periodic or infrequent exercise of trip valves can result in failure of the valve to move which, considering the plant safety requirements, will necessitate immediate turbine shutdown. Daily exercise of VHP trip valves will ensure freedom of movement of the trip valve and positively prevent unnecessary unit shutdowns.

This best practice has been recommended since the 1990s. When followed, it has resulted in zero lost time accidents and failure to trip incidents. When not followed, more than one catastrophic machine outage in critical (un-spared) machinery has occurred, that has exceeded three months in repair time.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.