Lower-Emission Oil-Recovery Tech Kicks Off Imperial’s Production at Grand Rapids Project

The project is designed to reduce greenhouse gas emissions by up to 40% compared to its current processes with the help of steam-assisted gravity drainage technology.

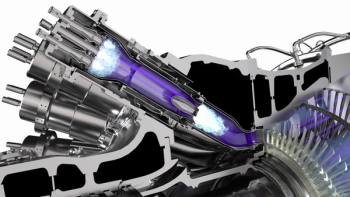

The Grand Rapids oil sands project, located at Imperial’s Cold Lake operating site in Canada, began production and marked the first commercial use of low-steam recovery technology to lower emissions intensity. Solvent-assisted, steam-assisted gravity drainage (SA-SAGD) was developed and piloted by Imperial and uses a lighter oil combined with steam to recover oil from subsurface deposits. Production will be scaled up over the next several months to achieve the full rate of 15,000 gross barrels per day.

“Grand Rapids represents a key milestone in Imperial’s plans to continue to lower emissions and deliver value for shareholders through high-value opportunities that continue to grow production and reduce costs,” said Brad Corson, Chairman, President, and CEO. “At Cold Lake, we are working to transition approximately 40% of production to lower emission technology by 2030. I want to commend the teams that have safely brought this project to production more than a year ahead of the original schedule.”

Over the next decade, Imperial plans to reduce GHG intensity to support Canada’s net-zero objectives. The company anticipates reduced Scope 1 and 2 emissions intensity from its oil sand facilities by 30% by the end of 2030. This goal will be supported by the implementation of SA-SAGD technologies at the Cold Lake operation, efficiency improvements, and the use of carbon capture and storage.

Emissions, especially methane, are being managed by a variety of private and public entities in Canada. With the help of the Canadian-based

Through the ETC program, Qube Technologies tested its fixed sensor that continuously, versus intermittently, monitors methane emissions. Since testing at the Tourmaline Oil/Perpetual Energy West Wolf Lake Plant—an ETC program host site—it has deployed over 4,000 sensors at over 1,000 sites, including Canadian operators such as Arc Resources, Enhance Energy, and Ember Resources.

Another example from ETC program is Kinitics Automation, a Vancouver-based company whose roots are in the automotive and power-generation industries. The company developed an electric valve actuator to replace methane-venting pneumatic actuators. During tests at one of the ETC program host sites—the University of Calgary and its labs—the actuator’s positional performance was evaluated at a variety of temperatures.

Outcomes revealed that the actuator reached the target positions within 0.1% at all tested temperatures and responded to motion commands of 0.25%—the smallest commanded value. In a differential pressure test, the actuator maintained a closed-valve state with a 4,000 kPa(g) differential pressure present across the valve. The electric valve actuator met or exceeded the performance of traditional pneumatic actuators.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.