Ansaldo Energia in Hungary: Generating Power for Flexible, Transition-Ready Grids

Stefano Gianatti of Ansaldo Energia says installing baseload flexible generation is key to supporting European countries struggling with renewable energy intermittency.

At the crossroads of decarbonization and available power lies baseload flexible generation, which many nations rely upon to sustainably balance grids with increasing renewable energy penetration.

“The strong global expansion of renewable energy sources has increased the need for flexible and reliable generation to compensate for their inherent intermittency,” said Stefano Gianatti, Executive Vice President of Thermal New Units at Ansaldo Energia.

The company recently signed a contract with MVM Tisza Erőmű to supply and maintain two gas turbines, two steam turbines, and two associated generators for a

Gianatti provided additional context about the Tisza project, Hungary’s grid-balancing efforts, modular power technologies, the company’s customer-focused investments and technologies, and more.

TURBO: What are the challenges associated with commissioning newbuild power plants and installing flexible generation? What’s the Tisza project timeline?

Gianatti: Commissioning newbuild power plants and installing flexible generation involve complex supply-chain management, integrating advanced technologies, and meeting stringent environmental targets. The Tisza project will feature two combined-cycle units for 1,000 MW total. The Tisza Combined-Cycle Power Plant is expected to enter operation four years from the commencement date, which is planned for autumn 2025.

TURBO: Which gas turbines will Ansaldo Energia use at the Tiszaújváros site? Is the site planning to use hydrogen blends immediately or in the near future?

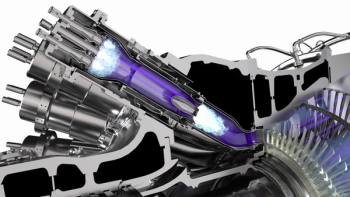

Gianatti: At the Tiszaújváros site, Ansaldo Energia will supply two GT26 gas turbines, each operating on natural gas and already capable of using up to 30% hydrogen in the fuel mix, with the potential to accommodate higher hydrogen concentrations in the future. While the plant will initially run on natural gas, it has been configured from the outset to support the gradual integration of hydrogen. This future-proof approach aligns with Hungary’s decarbonization goals and ensures the plant’s long-term viability.

TURBO: How does the Tisza project strengthen Hungary’s baseload power supply and overall energy landscape going forward?

Gianatti: With the Tisza project, MVM is taking a step forward in strengthening Hungary’s energy infrastructure and energy independence with our technologies, ensuring security, flexibility, and support for grid stability. GT26 efficiency, operational flexibility, and hydrogen readiness perfectly fit these goals. This commitment fits into the country’s broader strategy to modernize its energy system with Ansaldo Energia’s hardware and solutions, and we are proud to contribute to this vision.

TURBO: How does the Tiszaújváros site’s infrastructure and geography support or enhance the combined-cycle plant operations? What does this supply agreement mean for Ansaldo Energia?

Gianatti: Tiszaújváros offers excellent grid connections, water access for plant cooling, and nearby gas supplies. For Ansaldo Energia, this agreement means showcasing hydrogen-ready technologies and strengthening our presence in Central Europe in a strategic and forward-looking country.

TURBO: What challenges are your customers facing amid current power demands and a shift in U.S. energy policies? How is Ansaldo responding to these challenges?

Gianatti: Customers face energy transition pressures, higher production flexibility to cope with renewables in the grid, and regulatory shifts. Ansaldo Energia responds with flexible, efficient, low-emissions gas turbines, H₂-ready technologies, remote diagnostics, and advanced upgrade packages.

TURBO: Is Ansaldo considering any upgrades or investments to meet customer challenges and the changing energy landscape?

Gianatti: Ansaldo Energia has invested heavily in enhancing both the fuel and operational flexibility of its gas turbines and developing upgrade packages and digital solutions. Operational flexibility is necessary to allow efficient and dispatchable production, supporting the integration of renewables and ensuring grid stability. One example is our GT36 gas turbine, which features a load ramp-rate of up to 100 MW per minute and a minimum environmental load of only 15%. This responsiveness enables operators to quickly adapt to fluctuating electricity demands and the variability of renewable energy sources. By minimizing start-up times and maximizing part-load efficiency, operational flexibility not only supports grid reliability but also improves the plant’s economic performance, reducing fuel consumption, optimizing maintenance intervals, and lowering overall operating costs.

Speaking of fuel flexibility, our fleet is now ready to operate with hydrogen blends from 40% -70%, depending on the equipment, with the goal of achieving 100% hydrogen capability by 2030. Ansaldo Energia is also actively working on alternative low-carbon fuels, such as methanol and hydrotreated vegetable oil (HVO). These capabilities are being deployed in ongoing projects, such as the

In addition, our digital services—particularly the integrated plant support platform—provide real-time monitoring, predictive diagnostics, and performance optimization, ensuring our customers have the insight and support they need to meet today's complex energy challenges.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.