- May/June 2024

- Volume 65

- Issue 3

Curbing CO2: Technological Efforts to Reduce Carbon Emissions

Technology designed to reduce carbon emissions is supporting the power generation industry’s move toward decarbonization.

In 2022, total annual U.S. electricity net generation by utility-scale electric power plants (at least 1 MW of electric generation capacity) of about 4.23 trillion kWh from all energy sources resulted in the emission of about 1.65 billion metric tons of CO2, according to the U.S. Energy Information Administration.

With a continued emphasis on emissions reduction for the power generation and industrial markets, particularly in carbon and methane mitigation, companies are executing initiatives to address environmental concerns and meet sustainability goals. They are investing in upgrading equipment to reduce emissions and optimizing processes to streamline efficiency, thus minimizing the chance of excess CO2 leakage.

COMPONENTS TO REDUCE CO2

Companies like John Crane, MTU, and Siemens Energy are just a few participants in the carbon-reduction trend. Each has developed modified processes or new technologies to eliminate carbon output within their operations.

John Crane

John Crane retrofitted dry gas seals on oil and gas assets at a natural gas liquid extraction plant in the United Arab Emirates that wanted to lower emissions and operation/maintenance costs. The company replaced floating oil ring wet seals with dry gas seals on four centrifugal compressors. To accommodate the new dry gas seal cartridge, new seal housings for the low-pressure (LP) compressor were required.

Two Type 28XP seals were installed on the high-pressure (HP) compressors and two Type 28AT seals were installed for the LP tandem seal for the HP and LP compressors. Each unit was fitted with a Type 83 barrier, backed up by one seal gas support system with a nitrogen generator for each compressor. Following the retrofit, a rotor-dynamic study revealed a rotor instability issue. Thus, tilting pad journal bearings with squeeze film dampers were installed on the LP compressors.

The results of the retrofit are as follows:

- 97% reduction in CO2 emissions

- Reduced upgraded bearing-type rotor vibration

- Successful startup and commissioning of compressor trains one and two

- Increased compressor reliability

At a pipeline station in Oman, John Crane performed a turnkey retrofit of two large compressor trains from oil seals to Type 28 dry gas seals, with the addition of the following assets and work: a gas seal system with a gas conditioning unit, filters, and a heater; separation seals; rotor dynamic analysis and modifications; and installation and commissioning support. The dry gas seals required a unique design to fit into the seal cavities. The LP and HP compressors were disassembled so their rotor and compressor casings could be modified to fit the new seals cartridges.

The pipeline station experienced the following benefits:

- 98% reduction in CO2 emissions

- 2% less gas consumption during gas turbine combustion

- Eliminated process gas contamination and reduced oil removal costs

- Significantly reduced maintenance and energy costs

- Increased compressor reliability

MTU Maintenance Hannover

In December 2022, MTU Maintenance Hannover completed an energy project for a new office building and a nearby production facility. A heat pump was installed to provide both heating and cooling for the sites, supporting two gas-powered boilers by releasing and drawing ambient heat with the help of a compressor. Heating or cooling is released into the surrounding area through a water distribution system.

The heat pump produces different water temperatures throughout the seasons, cooling in the summer and heating in the winter. The cooling and distribution process generates 50° C warm water to be stored in buffer tanks, which is then heated further for varying production applications that require hot water. Considerable amounts of gas are saved by heating the water an extra 20° C instead of 40° C.

In the winter, cold water is transported back to the maintenance, repair, and operations plant to cool down its production machines. In the remaining seasons, spring and fall, the heat pump system lowers the temperature of warm water from the cooling network to 10°C. The cooling units’ electricity usage is lowered during this process. Annual carbon emissions can now be cut, as for every unit of electricity consumed, the system generates four combined heat and cold units. For 2023, MTU Maintenance Hannover was able to save 219 tons of CO2.

Sigrid Huber, Director of Work Safety and Corporate Environmental Sustainability at MTU Aero Engines, said the company’s increased use of photovoltaic installations through the MTU network has also supported reduced emissions. Currently, MTU Aero Engines is implementing geothermal technology at its Munich location to further decouple its operations from traditional energy sources. Once construction of the geothermal power plant is complete (the projected date is mid-2025), the site’s heat supply will be largely independent of fossil fuels, thereby significantly mitigating its carbon emissions.

SOFTWARE FOR CO2 REDUCTION

In addition to using physical components to minimize CO2 output, companies often create software solutions to monitor and record emissions data for operators to take the next step in mitigation. The software often incorporates artificial intelligence and IoT to enhance efficiency and accuracy in data reporting, allowing end-users to develop comprehensive strategies or technologies to abate recorded emissions.

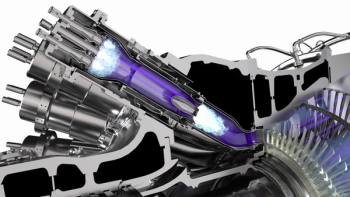

Siemens Energy’s Predictive Emissions Monitoring System (PEMS) enables operators to make informed decisions and develop strategies to cut back on carbon output. PEMS is a digital solution that can predict exhaust emissions with internal system engine parameters, as well as use data from the gas turbine to create an algorithm that generates precise emissions signatures.

In addition to the PEMS variant, Siemens Energy also produces a physical version of the technology: the Continuous Emissions Monitoring System (CEMS). The CEMS product relies on physical sensors to analyze gas extracted from the exhaust; however, the system uses calibration gases that demand consistent maintenance. Both solutions are highly adaptable, allowing customers in the energy industry to view the emissions footprint for NOx, CO, and CO2, and PEMS additionally reduces capital and operational expenditures.

PEMS is integrated with the Omnivise digital platform and is currently installed on several combustors around the world. Siemens Energy reports more than eight successful installations on dry low emission (DLE) and non-DLE combustors.

THE PATH FORWARD

As industries like power generation and oil and gas seek to curb their carbon emissions, a concerted effort is underway to adopt innovative technologies and strategies. Companies are investing in equipment upgrades and process optimizations to minimize CO2 leaks, aligning with global sustainability goals.

With continued collaboration between private companies, government agencies, and international organizations, the path to a greener future in the power generation and industrial sectors becomes clearer. As these initiatives progress, the industry is poised to achieve significant reductions in carbon emissions, paving the way for a more sustainable and efficient energy landscape.

Articles in this issue

over 1 year ago

Myth: Nothing Lasts Forever, Not Even Coatingsover 1 year ago

Q&A: Digital Ecosystems Optimize Plant Efficiency & Safetyover 1 year ago

Carbon Capture and Storage is on the Riseover 1 year ago

Turbo Tour: GE Vernovaʼs Gas Turbine Manufacturing Facilityover 1 year ago

Turbomachinery International: May/June 2024Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.