- September/October 2025

- Volume 66

- Issue 5

Steam Turbine Optimization for Mechanical Drive Applications – Part 1

Key Takeaways

- Axial flow steam turbines require optimization to handle diverse operating conditions, with OEMs standardizing designs due to impracticality of custom solutions.

- Aerodynamic optimization tools include turbine stage and velocity triangles, Euler equation, stage reaction, and loss models, enhancing efficiency and performance prediction.

Explore how blade dynamics, velocity triangles, and flow path analysis help operators achieve higher efficiency and reliability in steam turbines.

Axial flow steam turbines drive process compressors, pumps, and fans in a variety of industries and applications, spanning a wide range of turbine outputs and steam pressures. They operate in a diverse range of functions, from very low load conditions such as plant startup to overload conditions as dictated by API 612 requirements. Turbine flow paths also vary by end user, process licensor, and individual site conditions.

Due to the extensive range of operating conditions, optimizing one-off steam turbine designs is not feasible, nor is it practical to design new hardware or bladed components on a per-project basis. Original equipment manufacturers (OEMs) typically standardize the hardware and optimize the components to meet varying individual requirements.

This two-part article highlights some of the optimization methods used to evaluate each unique steam turbine application. Part 1 describes the available tools that designers can use to optimize aerodynamic design. Part 2 addresses flow path optimization and mechanical optimization considerations.

Understanding the influence that aerodynamic and mechanical designs have on each other is essential. The balance between these two critical areas ensures steam turbines can be designed to operate at high efficiency levels and withstand the wide range of operating conditions required for mechanical drive applications.

AERODYNAMIC DESIGN

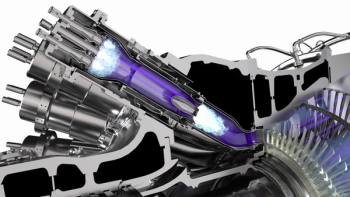

The Expansion Process

The core function of steam turbines is to convert thermal energy into mechanical work. Figure 1 shows the expansion process in a turbine on an Enthalpy-Entropy (H-S) chart. Steam enters the turbine inlet flange at high pressure (PO,IN) and total enthalpy (HO,IN). It expands to the exit static pressure (PEx) at the exhaust flange. The isentropic energy drop is DHIsen for lossless fluid expansion to PEx.As steam expands, the maximum amount of energy available for conversion to mechanical work (DHMax) decreases due to losses in the bladed flow path, as well as the flow components external to the bladed flow path, such as the trip and throttle valve, steam chest, governor valves, etc. Once actual work (DHActual) is extracted in the process, residual energy at the turbine exit is termed the leaving loss (HLL).

The maximum energy available, the actual work, and the leaving loss are related as shown in Equation 1. The leaving loss is proportional to the square of the velocity exiting the turbine, as shown in Equation 2. The overall turbine efficiency (η), as given in Equation 3, decreases due to the reduction in actual work as the leaving loss increases.

DHMax = DHActual + HLL (Eq. 1)

HLL = HO, Ex - HEx = (VEx2)/(2gcJ) (Eq. 2)

η = DHActual / DHIdeal (Eq. 3)

Tools to help designers optimize aerodynamic efficiency include:

- Turbine stage and velocity triangles

- The Euler equation

- Stage reaction

- The velocity ratio

- Loss models

Turbine Stage and Velocity Triangles

A turbine stage consists of a stator and a rotor. The stator is the stationary row that converts potential energy to kinetic energy. The rotor is the rotating row that extracts energy from the working fluid. The working fluid pressure drops across the stator, while it can drop or stay constant across the rotor. Velocity triangles help designers visualize how fluid moves through the turbine stage by illustrating the direction of flow and how it changes as it passes through the turbine stages. They represent the absolute velocity of the fluid, the relative velocity of the fluid in relation to the rotor, and the velocity of the rotor itself. Analyses of these velocity relationships gives engineers the information they need to:

- Design for energy efficiency.

- Optimize blade shapes and angles for effective energy transfer.

- Predict performance.

- Identify potential issues caused by changes in operating conditions.

Figure 2 illustrates a pressure-compounded axial turbine stage and velocity triangles. The three locations at which fluid properties and flow velocities are defined are Station 0, Station 1, and Station 2. Station 0 is at the inlet to the stage. Station 1 is common to the stator exit and the rotor inlet. Station 2 is at the rotor and stage exit. The velocity triangles at Station 1 and Station 2 are also shown where:

Absolute velocity, ft/sec (m/sec)

Blade speed at the mean diameter, ft/sec (m/sec)

Relative velocity, ft/sec (m/sec)

Axial component of the absolute velocity, ft/sec (m/sec)

Tangential component of the absolute velocity, ft/sec (m/sec)

Tangential component of the relative velocity, ft/sec (m/sec)

Flow angle of the absolute velocity vector w.r.t the tangential direction, °

Flow angle of the relative velocity vector w.r.t the tangential direction, °

The Euler Work Equation

The Euler Work Equation (Equation 4) relates the work extracted in a turbine stage to the stage velocity triangles. The work, or the heat drop, in an axial turbine is equal to the change in the angular momentum across the rotor. Assuming no change in the mean diameter (U1 = U2) across the rotor simplifies the Euler equation to the form shown in Equation 5, where the work is proportional to the change in the tangential component of the absolute velocity.

DHo = U1Cu1 – U2Cu2 (Eq. 4)

DHo = UDCu (Eq. 5)

where U = blade speed at the mean diameter

Cu = absolute frame velocity

Stage Reaction

Stage reaction is defined in terms of the pressure drop. The reaction is the ratio of the static pressure drop across the rotor to the static pressure drop across the stage, where the numerical subscripts refer to the stations defined in Figure 2. While the pressure reaction can have both positive and negative values, a negative value is not desirable.

An impulse (zero reaction) turbine is a special design, obtained when the pressure drop across the rotor is zero. The static pressure drop occurs only across the stator, while the work extraction in the rotor is only due to the change in momentum. As the reaction increases from zero, the proportion of work generated by the pressure drop in the bucket increases, while the proportion due to the momentum change decreases.

A reaction turbine is another special design with a reaction level of 50% that results when half the pressure drop occurs across the stator, with the other half occurring across the rotor.

The Velocity Ratio

The velocity ratio is a measure of how the work is being generated, either as a result of the turning in the rotor or due to the wheel speed. It is the ratio of the mean blade speed to the isentropic jet velocity for expansion from the stage inlet total pressure to the stage exit static pressure. The isentropic jet velocity represents the maximum energy available to the stage. For a fixed value of isentropic jet velocity, a turbine stage operating at a lower velocity ratio is extracting more work due to the turning in the rotor, while a turbine stage operating at a higher velocity ratio is extracting more work due to the wheel speed.

Turbine stage efficiency is a function of both the pressure ratio and the velocity ratio. For a given pressure ratio, the optimum velocity ratio condition is characterized by zero exit tangential velocity and peak efficiency. The optimum velocity ratio for a theoretical impulse stage is 0.5. In practice, the optimum velocity ratio for an impulse stage is less than 0.5 and is a function of the nozzle exit angle.

For a general stage design, the optimum velocity ratio is a function of the stage reaction. The optimum velocity ratio is greater than 0.5 for stages with a reaction greater than zero. For a 50% reaction design, the optimum velocity ratio is approximately 0.6.

Loss Models

Turbine stage performance is typically analyzed using 1-D flow solvers. These solvers are based on empirical loss models, which provide coefficients of the various loss components as a function of the airfoil geometry, characteristics of the cascade, and the operating conditions. The profile loss, the secondary loss, and the tip clearance loss are the major loss components. All losses lead to a reduction in turbine efficiency by decreasing the energy that can be extracted.

Profile Loss

Profile loss is related to the shape and characteristics of the turbine blades or vanes and occurs due to friction at the airfoil surface, the cascade loading, and, to a smaller extent, the geometry features such as maximum thickness, trailing edge thickness, etc.

The profile loss is a function of the pitch-to-chord ratio (s/c), the turning angle, and the incidence. The variation of the base profile loss coefficient, Yp, as a function of the s/c ratio and the bucket exit angle is shown in Figure 3. An increase in the airfoil count causes an increase in the frictional losses and a corresponding reduction in the loading losses. Reducing the airfoil count has the opposite effect, where the loading loss increases while the frictional losses decrease. The minimum total pressure loss occurs at s/c values where the combined losses due to friction and loading are at a minimum (Figure 4).

Incidence Effects

Incidence is the difference between the airfoil metal angle and the flow angle. A positive incidence is when the flow angle is less than the metal angle, while a negative incidence is when the flow angle is greater than the metal angle. The profile loss increase from positive incidence is steeper than that from negative incidence.

Secondary Loss

Secondary loss is the total pressure loss that arises near the inner and outer radii of the turning passage due to the boundary layers on the end wall and the flow turning. The secondary loss is greater for turbine passages with a shorter height since the end wall effects cover a larger volume of the passage.

FLOW PATH DESIGN AND OPTIMIZATION

Turbine Flow Path

A typical, straight-through, condensing mechanical drive turbine flow path consists of three distinct sections (Figure 5). These are the inlet (control stage), the group (HP/IP) stages, and the low-pressure (LP) stages. The mean diameter of each of these sections is defined separately in the design. The mean diameter of the inlet stage and the low-pressure stages depend on the casings selected. Both the steam end and the exhaust end are selected based on the maximum volumetric flow rate requirements and the pressure and temperature ratings of the casings. The rotation speed of mechanical drive turbines is typically determined by the driven equipment.

Inlet Stage

The inlet (control) stage is typically an impulse design that operates under conditions of partial admission to meet the varying load requirements and manage the variations in the volumetric flow rate. It is generally the least efficient stage in the flow path for the following reasons:

- Short blade heights

- High heat drop, even at moderate pressure ratios

- Partial admission losses.

The design pressure ratio of the inlet stage is usually dependent on two constraints:

- The inlet stage capacity should be sufficient to pass the maximum volumetric flow rate.

- At the maximum volumetric flow rate, the exit pressure of the inlet stage should not exceed the casing pressure rating.

The mean diameter of the inlet stage is also constrained by the nozzle port window dimensions in the steam end. The constraints may make it impossible to achieve the required mean diameter for the inlet stage.

Low-Pressure Stages

The low-pressure (LP) end of condensing turbines is designed by reapplying a predesigned grouping of matched stages. The predesigned LP end is also typically matched to individual exhaust ends in the inventory. Optimizing the selected LP end to specific project requirements includes minimizing the leaving loss, adjusting the height of and rotating individual stator and rotor rows to minimize row incidence. The leaving loss can be minimized by ensuring a large enough annulus area, which is a function of the rotor hub and tip diameters exiting the last stage blade.

Group Stages

Designers have the most flexibility when defining the mean diameter flow path of the group stages, including the blending of the mean diameter with the downstream low-pressure stages. The efficiency of the group stages as a whole is primarily a function of the stage count and the stage reaction. The stage count increases with the stage reaction.

Stage count affects both the performance and the geometry of the flow path. Not enough stages results in increased total pressure losses due to the increased stage pressure ratio and stage flow velocity. Due to the higher pressure ratio, increased stage loading requires more turning within the buckets, which also increases the total pressure losses. Increased stage loading requires an increase in the pitch diameter if the stages are to operate at the optimum velocity ratio. If the required diameter cannot be met, the resulting operation at a sub-optimal velocity ratio reduces efficiency.

Too many stages also reduce efficiency due to increased wetted surfaces. An increased stage count requires a smaller diameter for stages operating at the optimum velocity ratio. This could require step changes in the mean diameter that add to the total pressure losses in the flow path. Such a situation is likely in condensing turbines, where the low-pressure stages will be on larger diameters due to the high specific volume.

Optimization

Once mean diameter of the flow path has been defined, the flow path can be optimized by:

- Minimizing the last stage exit swirl to within 5 degrees from the axial

- Minimizing the bucket incidence

- Maintaining the velocity ratio at or close to the optimum value for the design stage reaction

Optimization is an iterative process that can be achieved by applying the appropriate inlet and exit metal angles, followed by rotating the airfoils to reduce row incidence and making incremental changes to the mean diameter and height.

Summary

Optimizing the aerodynamic flow path is critical to steam turbine design. However, balancing aerodynamic optimization with mechanical design considerations is essential. Part 2 of this article will discuss mechanical optimization considerations and the advanced analysis tools needed to evaluate each unique application in order to balance the aerodynamic and mechanical design.

Adam Neil is Director, Global Technical Services, Ebara Elliott Energy; Nikhil Rao is Sr. Aerodynamics Engineer, Ebara Elliott Energy; and Paul Smith is Sr. Engineer, Research & Development, Ebara Elliott Energy.

Articles in this issue

3 months ago

Myth: High-Speed vs. Low-Speed BalancingNewsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.