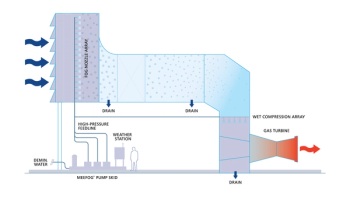

With U.S. power demand increasing due to data centers and ruled-out renewables, fogging and wet compression technology can help generate power quickly and inexpensively.

Turbomachinery Blog features postings from experts in all areas of turbomachinery, such as: gas turbines, machine diagnostics, materials, repairs, and aftermarket parts, and encourages users to participate, with reader engagement and interaction as its primary purpose.

With U.S. power demand increasing due to data centers and ruled-out renewables, fogging and wet compression technology can help generate power quickly and inexpensively.

Fogging and wet compression systems not only apply to gas turbines across power generation, oil and gas, and petrochemicals, but can also aid diesel and gas reciprocating engines.

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

Per Thomas Mee, installing fogging and wet compression technology may extract 10 – 20% more power output from the existing gas turbine fleet, countering longer lead times.

Although the upstream and midstream compressor markets are currently outperforming downstream, historic economic cycles suggest that a recession may arrive by 2031.

The relocation of North American manufacturing is driving the industrial compression trend in the Asia-Pacific region, as more gas and air compressors are needed to support growth.

Anthony Brough and Christean Kapp of Dora Partners & Co. address their new partnership with Turbomachinery International and highlight the centrifugal and reciprocating compressor markets.

Due to the low mole weight of hydrogen, one must increase impeller tip speed to generate higher pressure ratios and reduce overall stages.

With new power plants taking longer to come online, EthosEnergy helps customers extend their current assets through condition monitoring, refurbishment, and a commitment to efficiency.

Turbine Services Ltd. allows EthosEnergy to shorten component lead times, while the Operations & Maintenance division’s success is credited to reliability and consistency.

According to the CEO, EthosEnergy addresses long gas turbine-lead times and increasing power demand through maintenance, repair, overhaul, and lifecycle extension.

The May/June 2025 issue spotlights the gas turbine market, deep-diving into order activity, the impact of surging power demand, and how the industry is responding.

Matt Gentry of Airflow Sciences says faster processing speeds and improved computing allow flow models to present turbine data more quickly and accurately.

The March/April issue focuses on maintenance and repair and how data and AI are impacting the field and highlights our latest Turbo Tour.

The January/February 2025 issue gives readers an update on software and controls under the lens of AI and ML, the digitalization of compressor maintenance, and more.

This year, the turbomachinery industry was characterized by several trends—from technological innovation to gas turbines’ supporting role in renewably integrated grids.

The November/December 2024 issue highlights emerging decarbonization efforts that integrate hydrogen, ammonia, and new technologies into increasingly intermittent grids.

The 2025 Handbook includes a comprehensive outlook of the power industry and gas turbine market as well as an industry-wide directory and specifications listings.

The September/October 2024 issue highlights the dynamic shifts in the global LNG market that are affecting exports, production, capacity growth, and more.

At TPS 2024, Klaus Brun of Ebara Elliott addresses the company’s rebranding, prominent industry challenges, and upcoming products for sustainability and green energy.

The July/August 2024 issue offers comprehensive coverage on industrial and aeroderivative gas turbines, steam, and hydro turbines.

Turbomachinery operators can prevent leakage at pressure stations and pneumatically operated valves along the length of the compressor by using leak- or loss-free technologies, says NETL.

With Turbo Expo 2024 in London, held June 24 – 28, on the horizon, we’re looking back at insights from our interview with NETL at last year’s meeting.

The May/June 2024 issue features coverage of the growing carbon-capture industry, a tour of GE Vernova’s Facility in South Carolina, a Q&A on digital ecosystems with Emerson, and more.

The March/April 2024 issue features insight into how the oil and gas industry is reducing methane emissions, a micro-reactor Q&A with Rolls-Royce, a discussion with GE Vernova on decarbonization, and more.

Jean-Charles Bonaccorsi and Carolyn Woeber, Joint Application Engineering Directors at Cadence Design Systems, discuss the role of computational fluid dynamics in the design lifecycle, turbomachinery emissions, decarbonization, and more.

In part two of this two-part episode, Myth Busters Klaus Brun and Rainer Kurz cover the applications of digital twin technology, its advantages and limitations, and pairing it with AI.

In part one of this two-part episode, Myth Busters Klaus Brun and Rainer Kurz provide a background on digital twin technology and how it impacts the turbomachinery industry.

FS-Elliott's Dominic Sarachine discusses the company's takeaways from TPS 2023 and offers insights into air compressors and centrifugal compressor control systems.

The latest turbomachinery industry innovations.

Published: July 30th 2021 | Updated:

Published: September 28th 2021 | Updated:

Published: August 17th 2021 | Updated:

Published: February 22nd 2023 | Updated:

Published: August 24th 2021 | Updated:

Published: September 14th 2021 | Updated: