Many turbomachinery diagrams are outdated and recommend axial machines over centrifugals, but modern technological advancements must be considered for industrial applications.

Klaus Brun is the Director of R&D at Elliott Group. He is also the past Chair of the Board of Directors of the ASME International Gas Turbine Institute and the IGTI Oil & Gas applications committee.

Many turbomachinery diagrams are outdated and recommend axial machines over centrifugals, but modern technological advancements must be considered for industrial applications.

The loss of experienced personnel, underdeveloped manufacturing locations, and bottlenecked supply chains are posing significant challenges for building gas turbine capacity.

Klaus Brun and Rainer Kurz offer differing opinions on the necessity of high-speed versus low-speed balancing, citing API standards and diving into operating-speed discussions.

The perfection trap is just that: a trap—and often a costly, inefficient trap that leads to delays and even diminished operational flexibility.

Although torsional vibrations in turbomachinery trains are usually well-controlled, issues should be addressed proactively during the design process.

Most transient surge analysis software relies on significant assumptions about one- versus three-dimensional effects and presumes steady-state compressor maps.

Hydrogen transport and storage are technically challenging and present significant operational and safety issues that must be addressed.

Klaus Brun and Rainer Kurz explain root-cause analysis and how it assists operators in diagnosing turbomachinery failures.

Part two of this myth on centrifugal compressor maps delves into the map’s extrema: surge and choke.

Part one of this two-part myth on a centrifugal compressor map covers the basic physics of the constant speed head-flow performance lines.

Supercritical CO2 (sCO2) may not have superpowers, but turbomachinery operators try to avoid working near the critical point at all costs.

Turbomachinery coatings are designed to be an added layer of protection for base materials, but even coatings wear down.

CFD is a great tool, but it takes experienced engineers to get accurate results.

Green hydrogen is receiving a lot of hype in the news, but a closer look reveals how impractical its future is for power generation.

Part one of this two-part myth on reciprocating versus centrifugal compressors addresses design and application differences.

Open and shrouded impellers both offer advantages, which are reflected in the respective applications they are used for.

Reciprocating and centrifugal compressors are viable options for hydrogen compression with enhanced and adapted sealing methods, alternative valve selections, and additional staging.

Dual drivers—a combination of an electric motor and a gas turbine to power a centrifugal compressor—play on the individual strengths of each driver in a single package.

What are cross-coupling forces really, and should I judge my rotor system stability on them?

Debunking the Myth: Embracing Gearboxes for Enhanced Efficiency in Compressor Applications

The current trend in manufacturing is toward single-piece manufacturing. However, in many cases, there is no justifiable reason or logic behind this.

ANALYSIS METHODOLOGY IS KEY

Closed loop compressor performance test comparisons

Upgrades required for LNG to meet demand

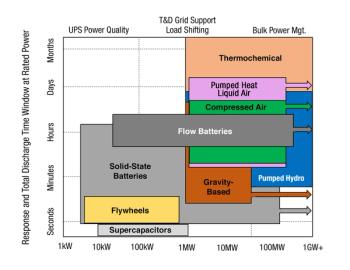

Klaus Brun and Rainer Kurz talk about summer electricity price gouging assumptions

Published: November 14th 2023 | Updated:

Published: July 25th 2022 | Updated:

Published: May 26th 2023 | Updated:

Published: October 7th 2022 | Updated:

Published: February 21st 2023 | Updated:

Published: October 28th 2022 | Updated: