Ansaldo Energia Improves Output, Efficiency at ENGIE Plant with MXL3 Tech

Ansaldo Energia’s MXL3 upgrade lowers emissions by up to 20%, boosts power output and efficiency, and enables 45% hydrogen co-combustion on its GT26 gas turbine.

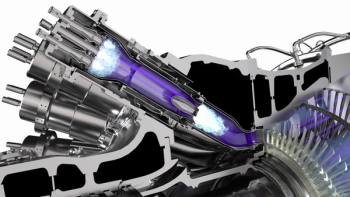

Ansaldo Energia installed its MXL3 upgrade at ENGIE’s Combigolfe power plant in Provence-Alpes-Côte d’Azur, France. The upgrade included a redesigned compressor with high-pressure-capable parts, an improved combustion chamber for Ansaldo’s GT26 gas turbine, H-class features to enhance performance in challenging conditions, and refined insulation. With these upgrades, ENGIE Flexible Generation France’s plant offers improved efficiency, performance, and a lower environmental footprint.

“We are proud of this achievement and grateful to ENGIE for our trusted and long-standing collaboration,” said Reto Furrer, Ansaldo Energia Executive Vice President Service. “This project strengthens the Combigolfe plant's role in delivering reliable and sustainable energy to the region and underscores Ansaldo Energia's commitment to innovation and sustainability in the power generation sector.”

The MXL3 upgrade resulted in:

- 2.3% increase in gas turbine efficiency

- 31-MW increase in power output

- Reduced fuel consumption and CO2 emissions

It also implemented a 45% hydrogen co-combustion capability with the potential to minimize emissions by up to 20%. Applicable across Ansaldo’s GT26 turbine fleet, the technology’s M and XL operation modes allow operators to alternate between optimized performance or optimized maintenance costs. This enhanced fuel flexibility is supported by the MXL3 combustor technology. Also, the upgrade extends maintenance intervals to 40,000 equivalent operating hours and minimizes scheduled or unscheduled plant downtime.

Installing the MXL3 technology required work from over 110 Ansaldo Energia experts and contributions from 20 additional companies across 10 nations.

Ansaldo in Hungary

Last week,

Once commercial operation starts, the 1,000-MW CCGT power plant will use its two-block construction to generate 7,500 GWh of electricity per year for Hungary’s power grid. In addition, the Tiszaújváros site offers current electricity grid connections, a cooling water system, and local natural gas access, making the MVM facility Hungary’s largest and most efficient plant to date. Ansaldo Energia gas turbine technology is hydrogen-suitable and operates with reliability, high efficiency, and operational flexibility.

Ansaldo in the News

The Hungarian contract follows Ansaldo Energia’s most recent turbine delivery in February, in which the company agreed to provide a hydrotreated vegetable oil (HVO)-fueled turbine for Ireland’s

The simple-cycle Tarbert Power Station will support and contribute to Ireland’s electricity supply, securing electrical power and providing critical electricity to the supply system during peak demand. Also, the plant will Ireland’s expanding renewable generation capacity. SSE Thermal’s project aligns with the European Union’s sustainability standards as Ireland moves toward cleaner energy solutions—HVO is lower carbon than traditional fossil fuels.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.