MIRATECH Acquires Advanced Catalyst Systems, Expands Manufacturing Capacity

Key Takeaways

- MIRATECH's acquisition of ACS expands catalyst manufacturing capacity, supporting growth in power generation, gas compression, and industrial applications.

- The integration of ACS enhances delivery speed, flexibility, and supply chain reliability, creating a catalyst center of excellence in East Tennessee.

The acquisition provides MIRATECH with increased catalyst production capacity, supporting growth across power generation, gas compression, and industrial/OEM applications.

MIRATECH recently acquired

“Our work at MIRATECH has always been focused on protecting people and improving the environments where they live and work,” said David Zenthoefer, CEO of MIRATECH. “Bringing ACS into the MIRATECH family allows us to extend that impact and meet the growing demand for our proprietary solutions. Their team, their technology, and their legacy of performance make this an exciting step forward for our customers and our industry.”

Combining MIRATECH and ACS will increase catalyst production capacity, supporting growth across power generation, gas compression, industrial/OEM, and emerging applications. The benefits also include improved delivery and supply resilience, with integrated operations across Knoxville and Maryville that enhance delivery speed, flexibility, and supply chain reliability.

“ACS has built its reputation by solving hard problems for customers who can't afford uncertainty in compliance or performance,” said Doug Campbell, President of Advanced Catalyst Systems. “Joining MIRATECH is a natural next step and, by combining our local knowledge with MIRATECH's global reach, we're well positioned to deliver greater value to customers worldwide.”

The ACS acquisition delivers accelerated catalyst innovation: Combined R&D teams and advanced coating and substrate technologies enable the faster development of next-generation catalyst solutions for stricter global emissions standards. MIRATECH will create a catalyst center of excellence in East Tennessee, supporting a stronger regional footprint in North America and internationally.

“The pace of change in our markets is accelerating,” said Zenthoefer. “Customers need partners who can innovate quickly and deliver solutions they can trust. Together with ACS, we are building one of the most capable catalyst development and manufacturing platforms in our industry.”

MIRATECH’s long-term initiative to expand its global footprint is reinforced by the acquisition, providing customers with regional expertise, manufacturing, and service support. ACS has served as a MIRATECH supplier and partner for many years, lending its technical capabilities, proprietary coating processes, and reputation for quality.

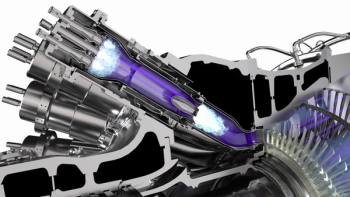

Ammonia Cracking Catalysts

In late October 2025, Mitsubishi Heavy Industries (MHI) and Nippon Shokubai

The ammonia cracking technology uses steam and exhaust gases and leverages an independently developed, low-temperature, highly active and highly durable cracking catalyst without deploying the noble metals typically used in conventional low-temperature active catalysts. Following NEDO’s approval, MHI and Nippon will conduct project activities through fiscal 2027 with long-term testing in mind, using a commercial-scale demonstration plant.

MHI will leverage its experience in ammonia plant construction and ammonia handling to execute the basic design and front-end engineering design. Hokkaido Electric Power will assist MHI in finalizing demonstration plant specifications, resolving technical challenges, and reaching commercialization. Nippon Shokubai will promote the development of elemental technologies to verify the durability of ammonia cracking catalysts, leveraging its experience and expertise in catalyst development and practical application.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.