TurboTime Podcast: Scheduled and Condition-Based Maintenance to Avoid Failures

Per Klaus Brun and Rainer Kurz, properly executed scheduled and condition-based maintenance methods are adequate to prevent failures, costly shutdowns, and interventions.

In this episode of the TurboTime Podcast, the Myth Busters Klaus Brun and Rainer Kurz address the most tried-and-true methods of avoiding turbomachinery failures: scheduled and condition-based maintenance. According to Brun, the AI emergence is generating discussions about improving these maintenance methods; however, Klaus and Rainer still stress that the primary way to avoid failures and/or shutdowns is to correctly perform timely maintenance, repair, and overhauls.

Kurz: Failures come in different flavors and severities, so you must examine the impact from an operator’s perspective. There are plants with redundant machinery, which makes their maintenance aspects seem more relaxed than plants with one critical piece of machinery—if this machine fails, production is down. It’s not just failure detection and failure prevention, [maintenance] also involves the logistics of spare parts: how they get onsite, sourcing locally, shipping internationally, and how the machine is maintained.

You’re not just trying to prevent your machinery from catastrophic failures—where things break and make the machine inoperable for extended periods of time—but you also have the degradation issue. The machine’s performance may not be good as new, so the question is: Do you want to fix it or live with it? For example, leakages in some systems don’t make the machine inoperable, but may lead to more serious problems in the long run. It’s a fact that any type of machinery eventually degrades and fails.

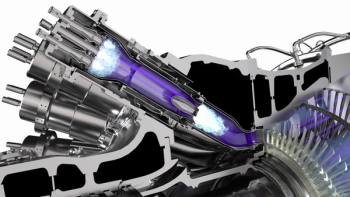

Brun: In most applications using a turbomachine, you’d want to run it continuously and you only have three types of interventions. One is when the machine trips, displays an alarm, and you must shut down. Next is a scheduled intervention; for example, after a certain time a combustor will have enough mechanical fatigue and you have to overhaul it. Then there is condition-based maintenance, which requires knowing the machine enough to potentially extend [time before overhaul] from 24,000 hours to 32,00 hours or even 48,000 hours.

There are three types of pieces. One is a piece that lasts forever—a compressor casing may last up to 25 – 40 years and never fail. There are also wear parts, like O-rings, seals, lube oil, and filters, and we know the lifetime of these pieces…you understand these lifecycles when you run the unit. Lastly, Rainer mentioned life-limiting parts. Pieces that—due to creep, thermo-mechanical fatigue, operating cycles, and an accumulation of stress factors—reach end-of-life and there’s not much to do about it besides replacement.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.