Ansaldo Energia Supplies AE94.3A Turbines, Generators for Al Dhafra Plant

The UAE-based 1-GW plant, connected to a nearby large-scale photovoltaic park, includes Ansaldo Energia’s 24/7 monitoring and technical support.

TAQA ordered four Ansaldo Energia AE94.3A gas turbines, generators, and associated services for its recently commissioned 1-GW Al Dhafra power plant in Abu Dhabi, United Arab Emirates (UAE). Under a long-term service agreement, Ansaldo Energia will provide continuous monitoring and technical support services for the Al Dhafra plant. The company will manage installation and commissioning work for the plant, which is expected to come online in May 2027.

“We are proud to contribute to this important project in the UAE,” said Stefano Gianatti, Executive Vice President of Thermal Power New Units, Ansaldo Energia. "The collaboration with TAQA is the crowning achievement of Ansaldo Energia's decades-long presence in the country. Abu Dhabi is home to Ansaldo Energia Gulf and our Middle East Service Hub, which play a key role in providing operational support to our customers in the area.”

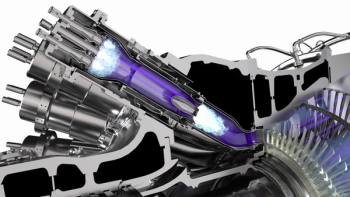

These AE94.3A gas turbines will strengthen the UAE’s overall energy infrastructure and security, offering high performance, operational flexibility, reliability, and cost efficiency. It can respond quickly to fluctuating grid demands, adapting to systems integrated with intermittent, non-dispatchable renewable energy sources. The Al Dhafra plant is connected to and supported by a large-scale photovoltaic park.

“Ansaldo Energia Gulf is also home to one of the two centers of our remote diagnostics system—Integrated Plant Support—which, in close contact with its twin in Genoa, ensures the continuous monitoring of turbines and generators installed in dozens of plants around the world,” said Gianatti.

In late April,

Once commercial operation starts, the 1,000-MW CCGT power plant will use its two-block construction to generate 7,500 GWh of electricity per year for Hungary’s power grid. In addition, the Tiszaújváros site offers current electricity grid connections, a cooling water system, and local natural gas access, making the MVM facility Hungary’s largest and most efficient plant to date. Ansaldo Energia gas turbine technology is hydrogen-suitable and operates with reliability, high efficiency, and operational flexibility.

Ansaldo’s MXL3

Last week, Ansaldo Energia installed its

The MXL3 upgrade resulted in:

- 2.3% increase in gas turbine efficiency

- 31-MW increase in power output

- Reduced fuel consumption and CO2 emissions

It also implemented a 45% hydrogen co-combustion capability with the potential to minimize emissions by up to 20%. Applicable across Ansaldo’s GT26 turbine fleet, the technology’s M and XL operation modes allow operators to alternate between optimized performance or optimized maintenance costs. This enhanced fuel flexibility is supported by the MXL3 combustor technology. Also, the upgrade extends maintenance intervals to 40,000 equivalent operating hours and minimizes scheduled or unscheduled plant downtime.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.