Assessing asset life cycle, condition, reliability, and performance

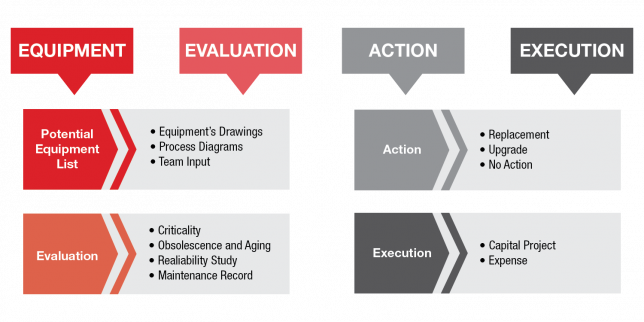

Comprehensive asset management consists of four main pillars: asset life cycle, asset condition management, asset reliability, and asset performance monitoring.

Asset Life Cycle:

Under this pillar, the equipment road map must be initiated. The first and most important step is setting a list of equipment. Information for equipment is gathered, such as drawings, data sheets, process diagrams, and input from different disciplines. The second step is the evaluation process, comprised of a criticality assessment. This includes equipment obsolescence and age, previous reliability studies, and maintenance records. The third step defines the action needed for each equipment item, such as replacement, upgrade, or no action is required. The final step is choosing how and when the action will be executed. Is it going to be through capital project or expense?

Asset Reliability:

The main purpose of this pillar is to monitor critical equipment reliability and interference before failures occur. There are two main programs under asset reliability; reliability technical alert and key performance indicator.

Reliability technical alert is a proactive recommendation that requires immediate attention to guarantee equipment reliability and availability. An example of this comes from the Abqaiq Plants facility in Saudi Arabia, one of the world’s largest oil stabilization plants that includes more than 840 pumps, 30 compressors, 110 steam turbines, and 10 gas turbines. A motor failed at the plant due to internal cable damage, causing electrical grounding. The repair cost of the first motor was $47,424, without including installation, and removal of the motor. During investigation of the cause of the fault, the team noticed an internal cable in contact with an internal support. This contact caused friction, cable insulation deteriorated and led to ground failure. A Reliability Technical Alert was issued to open and inspect the internal condition of sister motors. Signs of similar insulation deterioration were found. The team reinforced the insulation and returned the motor to service.

Key Performance Indicators

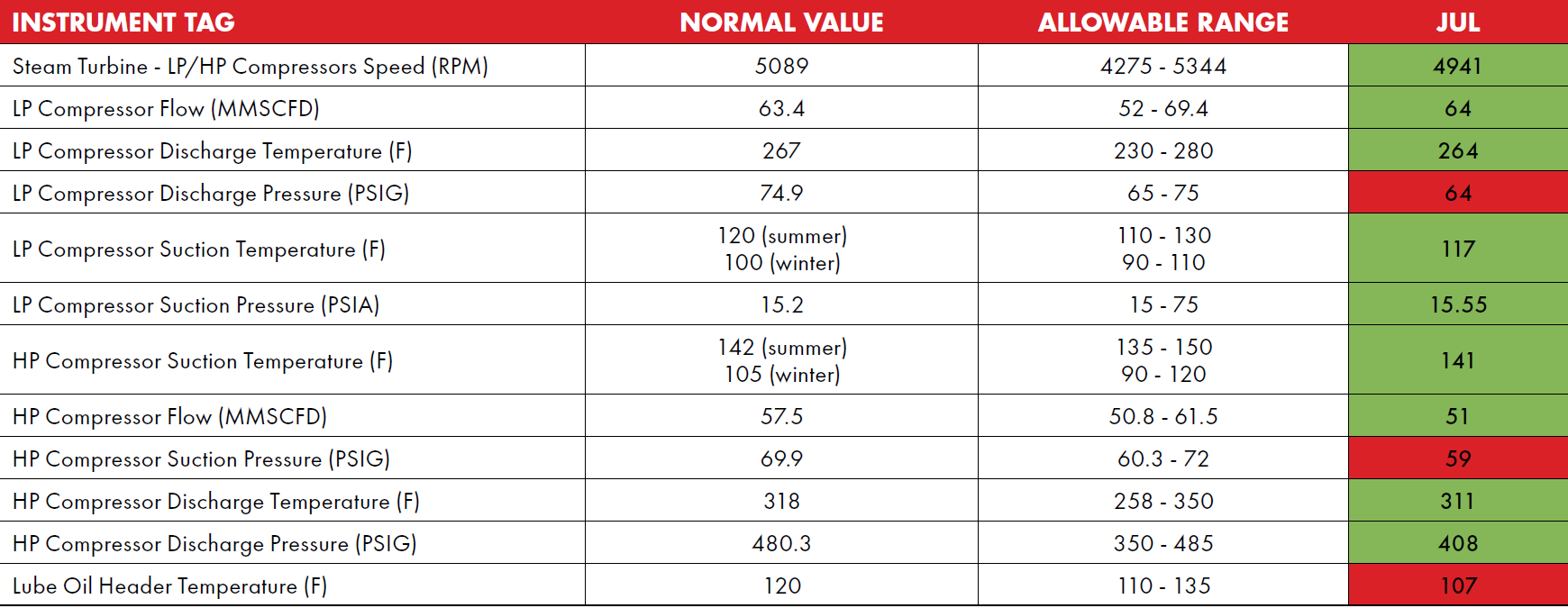

Key Performance Indicator Program:

Different processes and mechanical parameters are monitored on a monthly basis, such as suction/discharge pressures and temperatures, flow, and bearing vibration and temperature. The normal and allowable range of each parameter is defined to identify any abnormal reading. This allows the reliability engineer to compare values from different months, as well as acting on and providing recommendations before reaching alarm conditions.

Asset performance monitoring: Critical assets are monitored. If a certain item failed more than twice a year, it is included in the bad actor program. Long- and short-term recommendations are tracked until the equipment graduates from the bad actor program. Once graduated, it remains on the list for three months under monitoring to ensure the effectiveness of recommendations to solve and tackle the root cause of the failures.

Asset condition monitoring:

This is the most important pillar. It must be understood that one technology cannot do everything. Each technology has a specific field and benefits. All condition monitoring tools require a strong foundation based on establishing a guideline, creating new inspection routes and baselines for each tool, selecting the best reporting mechanism, and establishing a database. Further, all tools must be synchronized with the maintenance management system.

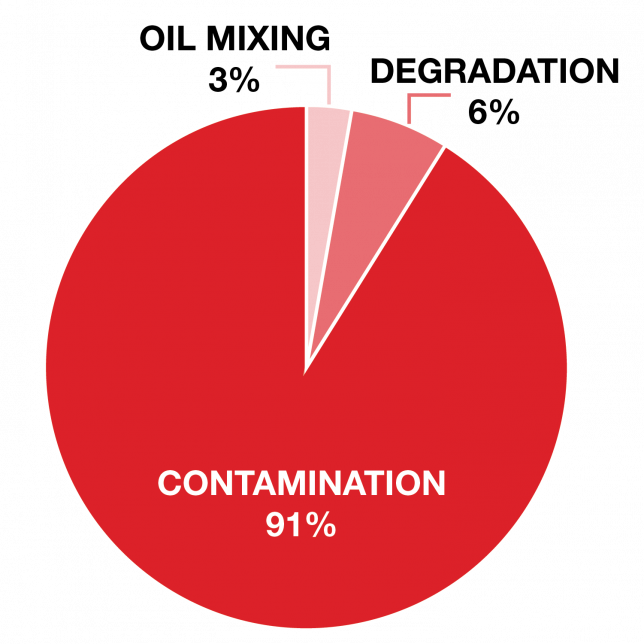

Lubrication analysis highlighted problems with water contamination due to the high number of steam turbines at the plant.

Condition monitoring

Different condition monitoring programs

utilize specific tools. This includes lubrication monitoring, thermography inspection, ultrasound, and vibration monitoring.

Lubrication monitoring is one of the fundamental condition monitoring programs as lubrication decreases friction, reduces wear, protects from corrosion, and absorbs heat. According to SKF, over 40% of maintenance costs are related to poor lubrication.

In the Abqaiq Plants oil samples are monitored for 89 equipment items. Physical and chemical property analysis is performed quarterly to look for issues such as bearing particles in the oil. Failure modes of lube oil samples are categorized as follows: oil mixing, degradation, and contamination.

Thermography inspection incorporates a multifunction noncontact application that can be applied for different condition monitoring programs (electrical system faulty electrical connection and overload, mechanical equipment abnormal heat, fluid systems line blockage, and temperature). The Abqaiq plant monitors two hundred items through thermography technology.

For example, thermography was used to detect a mechanical seal cooling blockage for a 500 HP pump. The team noticed low temperature on one side of the mechanical seal flushing line after the cyclone separator. This gave an indication of low flow on the pipe. The pipe was opened for inspection, finding dirt accumulated on the circulation line of the mechanical seal. This would cause a mechanical seal failure due to low flow, which would then lead to mechanical seal face damage. The cost avoidance of this case was $27,000

(without considering man hours).

Ultrasound is used on 400 equipment items on a monthly basis at the Abqaiq Plants. Although it can be used to predict different failures, such as passing valves, steam trap defects, and a lack of lubrication on rotating equipment, it is mainly utilized to monitor the lubrication condition of the rotating equipment, especially bearings that are lubricated with grease. In most cases, ultrasound can determine the lack of lubrication before vibration occurs. A baseline (dB) must be determined for each bearing, and this can be a challenge. In ideal conditions, the dB should be set based on newly installed bearings. If not possible, set it by comparing the dB reading of sister machines with the same species.

Vibration monitoring is used on equipment that lacks an online monitoring system. More than 1,100 equipment items are monitored on a monthly basis at the Abqaiq plant.

Asset management can reduce downtime, unplanned failures, and maintenance costs while improving asset life, prioritizing maintenance activities, and increasing the effectiveness of maintenance management. ■