Hanwha Power Systems, TC Energy Commercialize sCO2 Power Generation with Waste Heat Recovery

The sCO2 power generation system will be installed at TC Energy’s compressor station in West Virginia, recovering unused waste-heat exhaust from a gas turbine compressor.

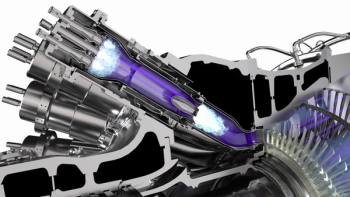

Hanwha Power Systems Co. (Hanwha) and TC Energy signed a memorandum of understanding to develop a supercritical CO2 (sCO2) waste heat recovery project to leverage the heat stream at a natural gas pipeline compressor station. An unspecified gas turbine OEM will also participate by verifying a combined power generation solution, integrating gas turbines with Hanwha’s sCO2 system.

Hanwha will install its sCO2 power generation system at a compressor station owned and operated by TC Energy in West Virginia. The system will offer a lower cost and carbon-free renewable generation solution, recovering unutilized waste-heat exhaust from a gas turbine compressor.

Hanwha’s sCO2 System

Under conditions exceeding 31ºC and 74 bar, sCO2 is a fluid that exhibits both liquid and gas properties. Hanwha’s system combines the properties of sCO2 with its integrally geared turbomachinery technology to contain the fluid in a closed-loop system and utilize waste heat. Additional aspects and features include:

- High efficiency

- Small footprint

- Modularity

- 100% water-free

- Does not require fossil-fuel combustion

Project Significance

According to Hanwha, the installation will reduce the carbon intensity of natural gas pipeline operations while producing clean, emissions-free electricity. This project—expanding Hanwha’s sCO2 power generation business in the North American pipeline market—will assist commercial viability and large-scale deployment in the industry.

“This memorandum of understanding with TC Energy brings us one step closer to the successful commercialization of sCO2 power generation systems,” said Justin (Koo Yung) Lee, CEO of Hanwha Power Systems. “We will continue to contribute to carbon reduction in the oil and gas market by successfully expanding the application of sCO2 power generation systems across a wide range of compressor stations. Hanwha is excited moving forward as this partnership shall accelerate Hanwha Power Systems' progress towards developing clean power generation solutions.”

More Hanwha News

In August 2023,

And, in October 2023, Kawasaki Heavy Industries (KHI) received an order for a singular 8 MW-class

This steam turbine generator set will replace an older model delivered by Kawasaki in 1987, which had been utilized for captive power generation by Hanwha. Power generated by the steam turbine unit will be consumed within the plant and heat will be managed for energy savings and CO2 emissions reduction.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.