Tennessee Valley Authority’s Scott Hunnewell discusses nuclear’s reliability as a carbon-free energy source and its increased safety due to passive safety systems.

Tennessee Valley Authority’s Scott Hunnewell discusses nuclear’s reliability as a carbon-free energy source and its increased safety due to passive safety systems.

The test phase will also verify the safety and performance of MITSUI E&S’s ammonia fuel-supply system and peripheral systems.

Jeff Benoit and Bobby Noble discuss the reliability and flexibility of gas turbines and how they satisfy many needs within power generation.

The Pierrefonds waste-to-energy plant, using a 19-MW steam turbine, will process up to 148,000 tons of waste and generate 121,000 MWh of electricity annually.

Scott Hunnewell of the Tennessee Valley Authority discusses how nuclear is moving from talking about nuclear to actually building nuclear.

The Raven Field’s initial phase developed eight subsea wells, located up to 65 km offshore, at water depths ranging from 550 to 700 meters.

Billy Sanez, Director of Global Marketing at SpotSee, addresses the risks of aerospace component transportation and how asset condition monitoring may help.

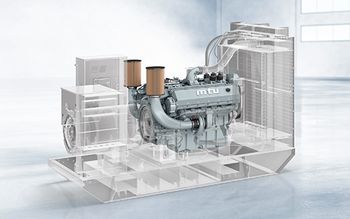

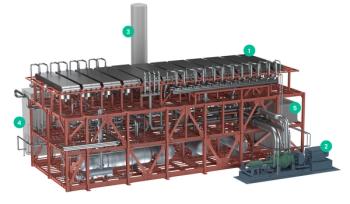

The engines and associated cooling systems will be available for purchase by independent OEMs for integration into their own genset designs.

Once operational, the plant's two gas turbines will generate a combined 990 MW, representing nearly 7% of Morocco's national grid capacity.

Boualem Hadjerioua of Mesa Associates addresses the benefits of hydro turbine technology, additive manufacturing, and low- and high-head operations.

Paul DiMascio of ProEnergy discusses how a direct ammonia injection system impacted emissions, costs, footprint, and efficiencies.

At POWERGEN 2025, Boualem Hadjerioua of Mesa Associates covers the roadblocks of hydropower buildout, latest tech innovations, modularity, and more.

Paul DiMascio of ProEnergy discusses how direct ammonia injection systems simplify NOx and CO removal.

INEOS, Royal Wagenborg, and Royal Niestern Sander shipyard will develop a liquefied CO2 carrier, expected to enter service by year-end 2025.

The facility includes existing dock infrastructure and onsite tankage with an LNG storage capacity of 107,000 m3.

The combined-cycle power station will feature two Siemens Energy SGT6-9000HL high-power-output gas turbines with hydrogen adaptability.

The project team identified which Royal Air Force Tornado components can be atomized into powders for additive manufacturing to make new engine parts.

The EC-8 control system uses the BACnet protocol and Modbus to enable communication and information exchange between machines and sensors.

The company will deliver gas compression trains, propane compressors, liquefaction trains, and a power island to the Jafurah Gas Field and Plaquemines LNG.

GE Vernova installed advanced gas path upgrades on 9.E gas turbines and MXLII upgrades on 13E2 gas turbines, increasing power output up to 6%.

Roots Blowers Systems manufactures displacement blowers engineered to deliver a steady volume of air with each rotation.

The simple-cycle, bio-fueled station will be powered by Ansaldo’s AE94.3A turbine.

Arrow Engine distributes natural gas-powered engines through a global distribution network, with primary focus on the United States and Canada.

The company’s modular capture plant design reduces capital costs, minimizes the impact on existing factory operations, and easily facilitates integration with pulp mills.

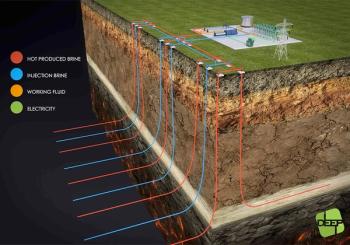

The approach will leverage the natural permeability of the sedimentary rock formation and enable reliable, cost-efficient, and sustainable geothermal energy production.

The next phase of testing will focus on performance and emission optimization, including injection, selective catalytic reduction systems, and control strategies.

The digiPrime pump, anchored by a 3,000 hp Cummins natural gas variable-speed engine, is a direct drive solution with significant thermal efficiency.

The investment will satisfy increasing customer demand, bolster national supply chains, and allow GE Vernova to continue developing its power technologies.

The company completed and commissioned 70 km of gas pipelines and 21 modular compressor units across seven Uzbekistani oilfields.

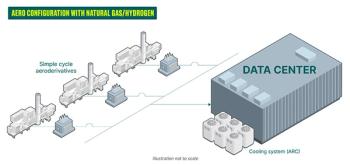

The multi-GW scale power plant, co-located to a data center, will use flexible power to support lower carbon solutions and renewable energy.