The Homer City Energy Campus will utilize natural gas extracted from the Marcellus Shale, delivering up to 4.5 GW to address local data center-driven energy demand.

The Homer City Energy Campus will utilize natural gas extracted from the Marcellus Shale, delivering up to 4.5 GW to address local data center-driven energy demand.

The GTF Advantage engine increases payload capacity, extends flight range, and lowers CO2 emissions with improved take-off thrust and fuel efficiency.

Andres Galnares, CEO of H2SITE, says the palladium-alloy membrane simplifies hydrogen transportation through onsite generation with carrier molecules.

Dr. Delgado says Turbo Lab graduates are engaged with classes and real-life operating experience before entering the OEM and end-user workforce.

Rolls-Royce will install the NautIQ Foresight system on a pilot vessel, collecting performance data to improve automation for future testing.

Natural gas-powered thermal generation, carbon capture, and hydrogen must complement renewable energies as grid stability and capacity becomes paramount.

The TM2500 turbine will provide emergency power for utilities, municipalities, data centers, and other industries with its rapid start-up cycle.

Industry leaders are adapting maintenance strategies to incorporate data-driven insights and provide rapid, efficient solutions that keep critical equipment running.

The new industrial gas turbine field-service shop will house an engine dock and apprentice workshop to train and qualify mechanics.

The gas-bearing equipped system maintains stable performance during changes in atmospheric pressure, specifically in low-density air flights.

Springfield City Utilities will require increased power generation capacity by 2026 due to higher electricity demand, aging power assets, and extreme weather events.

The Turbomachinery News Network, for the week of March 24, 2025, covers news from GE Vernova, GE Aerospace, Baker Hughes, Kawasaki Heavy Industries, and LNGameChanger.

The maritime LNG-fired power train combines solid-oxide fuel cells with onboard CO2 liquefaction and storage, decarbonizing maritime transport vessels.

The funding covers new machines, test cells, inspection technologies, and more across Italy, Poland, the Czech Republic, the United Kingdom, and Romania.

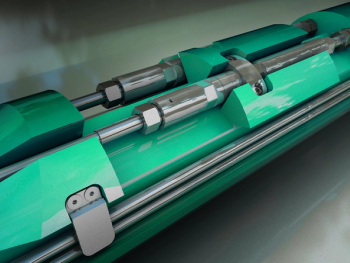

The CoilTrak coiled-tubing system, in combination with integrated compressor lines, establishes a reliable power system with reduced CO2 emissions at the Margham project.

The centrifugal hydrogen compressor uses a newly developed impeller to handle high flow rates, boost hydrogen pressure, and improve liquefaction efficiency.

XEOS is currently supporting LEAP-1B and 1A shop visits, module work, and engine testing, and it plans to expand overhaul capacity and repair capability in the coming months.

The dual-fuel engines will allow Karpowership’s power-plant barges to use various available fuels specific to their operating locations in energy-starved regions.

Increased vehicle loading and transport capacities allow greater leeway in the ship allocation schedule, securing more holiday and rest time for the crew.

The Turbomachinery Laboratory at Texas A&M researches compressors, turbines, and pumps, fostering collaboration between academia and industry.

The project demonstrated the culmination of Saudi Arabia's engineering talent development, including training, certifications, practical experience, and more.

Four key distributors will expand their parts, compressors, and additional products and services across Ohio, Pennsylvania, West Virginia, and more.

John Bartos of Rotating Machinery Services says South Houston’s BJ Superior contributes its in-house inspection, manufacturing, and refurbishment capabilities.

Petrobras will use the SureCONTROL Premium interval control valve to enhance operational reliability in its high-flowrate offshore fields.

The Turbomachinery News Network, for the week of March 17, 2025, covers news from Chart Industries, Cheniere Energy, the U.S. Department of Energy, Rolls-Royce, and Baker Hughes.

Greg Gammon of Texas A&M says that partnerships across hydraulics, vibration, power, and propulsion allow for direct industry engagement.

The duplex and in-line pressure filters suit industries requiring minimized downtime, uninterrupted operation, and tight operational schedules.

The first commissioned vessel is powered by four mtu Series 4000 gas engines and two controllable pitch propellers, reaching a max speed of 23 knots.

The project is subject to Nuclear Regulatory Commission approvals and is the first American reactor to restart after ceasing operations.

CO2-induced corrosion is common in Brazil’s pre-salt fields, where Petrobras reinjects CO2 from its production operations into wells to decrease flaring and boost oil recovery.