MFM generates an alert and technical recommendations for the operator, preventing further degradation that may cause damage and unplanned shutdowns.

MFM generates an alert and technical recommendations for the operator, preventing further degradation that may cause damage and unplanned shutdowns.

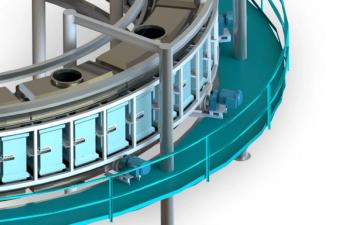

The Netherlands-based plant uses SLB Capturi’s Just Catch modular system, which reduces onsite installation and outfitting work for lower costs and ease-of-deployment.

Cryo-Mach will expand Dover's participation in liquified oxygen, argon, and nitrogen in the industrial gas and transportation markets.

The plant will produce approximately 200 GWh of e-methane for heavy road and maritime transport per year, as well as 180 GWh of CO2-free district heating for Tampere’s system.

The tool has been re-engineered to have a smaller footprint, a better price-point, and testing on angle.

The company will provide long-term turbine maintenance under a 25-year agreement.

Michael Stipa and Aslan Karaismailoglu of Rolls-Royce share how mtu gas-fired gensets help customers operate independently from the national grid.

Users can transition toward measurement-supported methane accountability, improving operational efficiency and safeguarding their market position.

These awards kick off Phase 1 activities and the hubs’ use of energy resources, existing infrastructure, electrolyzers, and more to reduce carbon emissions across heavy industries.

The East Texas facility will serve as a buffer to balance natural gas supply and demand, ensuring continuous service during times of peak electricity demand.

This project will enable oil and gas operators, tribes, and other U.S.-based entities to reduce, monitor, measure, and quantify oil and gas methane emissions.

Svante will capture, compress, condition, and liquefy CO2 emissions, and Tenaska will manage CO2 transportation and sequestration.

Brightmark partners with farmers to produce RNG through anaerobic digestion to collect and digest organic waste to extract methane and upgrade it into RNG for use as fuel.

With new financing, Amogy will continue developing and commercializing its ammonia-to-power systems in the maritime shipping and stationary power generation markets.

The facility will produce up to 800,000 MTPA of clean ammonia and connect to nearby natural gas and CO2 sequestration infrastructure.

Celeros and Flowserve will develop high-pressure injection packages for ADNOC’s Habshan gas plant, capturing and storing 1.5 million tons of CO2.

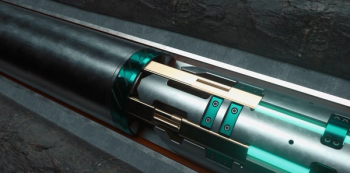

SureCONNECT FE allows operators to implement fiber-optics monitoring, electronic monitoring, and electric intelligent completion systems in land- and sea-based wellbores.

Rotating Machinery Services conducts specialty repair, maintenance, overhaul, and custom manufacturing for critical OEM and non-OEM turbomachinery infrastructure.

The 104-mile, high-pressure gas gathering pipeline connects natural gas supplies from the Williston Basin to high-demand markets in the northern United States.

The turboshaft engines will be built and delivered under a contract with the U.S. Army through the government’s Foreign Military Sales process.

The Whale’s estimated peak production is 100,000 gross boe/d, with up to 15 wells under development and equipped with energy-efficient gas turbines and compression systems.

Rolls-Royce’s Trent XWB-97 aero engine powers short- and long-haul flights across passenger and freighter operations.

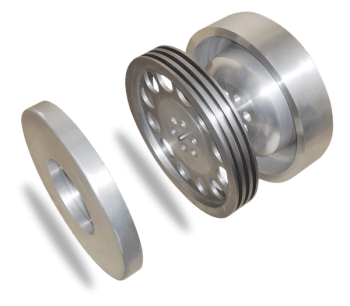

Global Compression Services issues OEM and aftermarket components and manufactures specialized parts tailored to the natural gas sector.

Ana Amicarella, CEO of EthosEnergy, said One Equity Partners’ expertise in mergers and acquisitions will help expand service offerings and improve operational efficiencies.

Harbin Electric and GE Vernova delivered steam turbines, generators, and three 9HA.01 gas turbines, producing 2 GW of power to satisfy China’s decarbonization goals.

The plant has no access to the public grid, so each Rolls-Royce mtu genset supplies 2,500 kW of electric power to manufacture medium-density fiberboard.

Residential and commercial heat pump programs aim to develop pumps that perform at sub-zero temperatures and as emissions-effective rooftop units.

The new power plant replaces the current facility and reduces natural gas consumption by 15%.

The new lubricants and additives include FSE-TurboCool 32 and 46; FSE-TurboCool PG; FSE-TurboCool FG; and FSE-TurboCool CC to minimize downtime and extend lifespan.

The project adds 423,400 Dth/d of fully contracted pipeline capacity, two new all-electric compressor stations, and upgraded metering stations to accommodate demand.