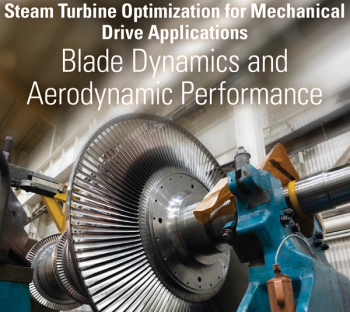

The September/October 2025 issue covers steam turbine optimization, a pump-centric conversation with the Hydraulic Institute, hybrid grid technology for stabilization, and much more.

The September/October 2025 issue covers steam turbine optimization, a pump-centric conversation with the Hydraulic Institute, hybrid grid technology for stabilization, and much more.

In addition to servicing critical oil and gas safety systems, EthosEnergy’s Approved Repair Facility designation will enable faster turnaround times and localized support.

The Turbomachinery News Network, for the week of October 6, 2025, covers news from Turboden America, Siemens Energy, Ansaldo Energia, Everllence, and Rolls-Royce.

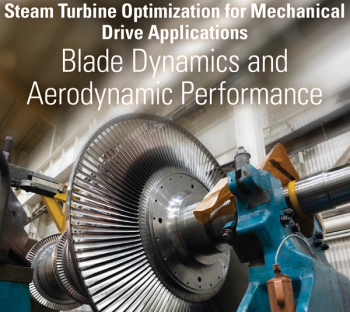

The refurbishment covers engineering studies, manufacturing, on-site dismantling, installation, and long-term maintenance operations for Unit 1 at Cernavoda Nuclear Power Plant.

The TCT40 turbocharger features a newly developed radial compressor and axial turbine, reinforcing a compact and lightweight design with superior charging efficiencies.

Following expansion in New Mexico and Texas, Cardinal now owns and operates approximately 150 miles of natural gas infrastructure in the Delaware Basin.

By using a fast-starting independent gas power plant, data center operators may come online faster with increased energy security and electricity to the grid.

In addition to providing heating and hot water supply for commercial facilities, the ETI-W can serve the electronics, automotive, food, chemical, and pharmaceutical industries.

Large-scale gas turbines will be installed at two Xcel Energy facilities, retiring an older coal plant and powering a new peaker plant that will respond to high-demand periods.

Cape Station’s Phase II engineering and procurement scope includes Turboden’s turbines and control system, expected to generate 300 MWe of power following delivery in 2028.

The Turbomachinery News Network, for the week of September 29, 2025, covers news from Mitsubishi Power, Kawasaki Heavy Industries, Baker Hughes, bp, and Rotating Machinery Services.

The company’s compressor testing suggested that single-piece rotor manufacturing enables higher tip speeds, which maintains an optimal pressure ratio for compressing hydrogen.

Following the upgrade, Alpiq’s San Severo power plant may operate with up to 25% hydrogen, improved operational flexibility, and lower CO2 emissions per year.

The new headquarters will house advanced capabilities such as laser scanning, virtual assembly, metrology, and much more, allowing RMS to serve Gulf Coast customers quickly.

The key liquefaction equipment, including Frame-7 turbines and centrifugal compressors, allows Sempra Infrastructure to expand LNG export capabilities in the United States.

Jiangsu Lihuai Steel’s gas turbine combined-cycle plant will use the M100S gas turbine, which can co-fire various gases generated as byproducts from steel plant equipment.

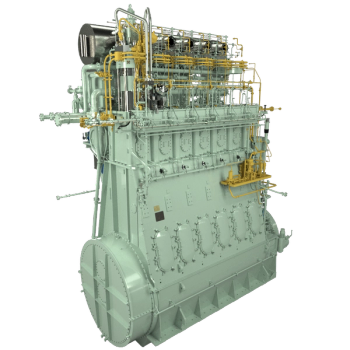

The large-scale hydrogen co-firing engine features hydrogen leak detectors and nitrogen purge systems, with the ability to adjust the co-firing ratio during operation.

The non-contacting, gas-lubricated seal offers simplicity of maintenance, reduced downtime, and significantly minimized power consumption—up to 90 – 95% less usage.

The company is using existing platform and subsea equipment designs to improve cost efficiencies for the hub’s construction, commissioning, and operations.

The Ansan Smart Hub will be converted into a high-efficiency, eco-friendly power plant capable of accommodating a future fuel conversion from natural gas to hydrogen.

Mechanically sealed pumps are subject to cavitation damage, thermal shock, and more when operating with ammonia, so operators deploy sealless designs to counter corrosive effects.

The natural gas-fed pipeline system will be expanded in Texas, New Mexico, and Arizona, with potential bidders supporting markets in the Desert Southwest.

The Turbomachinery News Network, for the week of September 22, 2025, covers news from Rolls-Royce, Doosan Enerbility, Everllence, and Siemens Energy.

The planned 11-GW AI campus will pair natural gas generation with nuclear power, leveraging Siemens Energy’s F-class gas turbines, steam turbines, and Westinghouse AP1000 reactors.

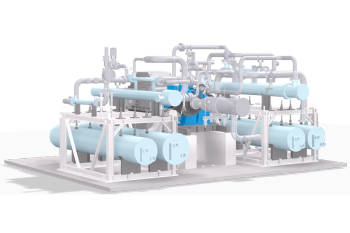

Dr. Marco Ernst of Everllence says that deploying multiple centrifugal compressor trains allows the company to cover compression from capture to offshore transmission.

The plant will capture, purify, and liquefy up to 30,000 tons of CO2 per year, which is then transported via tanker for use in the food industry.

The dual-fuel engines will each supply 18.5 MW of power to build Mauritania’s electricity supply, while the 90-bore ME-LGIM engine successfully burned ethanol at all load points.

With some mechanical and hydraulic modifications, conventional centrifugal pumps can handle supercritical fluids better than most centrifugal compressor designs.

Korea Southern Power and Doosan Enerbility will use Korean-made products in its pumped-storage hydropower projects, strengthening local manufacturing and engineering industries.

The European Union’s Clean Aviation Joint Undertaking aims to transform aviation toward decarbonization, sustainability, and new propulsion concepts.