Lukas Biyikli of Siemens Energy discusses carbon capture, including the role of gas turbines, removing CO2 from flue gas, and boosting CO2 concentration in exhaust gas.

Lukas Biyikli of Siemens Energy discusses carbon capture, including the role of gas turbines, removing CO2 from flue gas, and boosting CO2 concentration in exhaust gas.

Federal investment allows manufacturers to produce additional residential heat pumps, residential heat pump water heaters, school heat pumps, and heat pump compressors.

To support the 2050 carbon-neutrality plan, Taiwan Fertilizer Co. (TFC) will use blue and green ammonia as fuel in Taiwan.

The composite tubing can reduce the chill-down time, hydrogen boil-off, and the dry mass of cryogenic fluid transfer lines.

The two companies are expanding their joint venture, MTU Yuchai Power, which manufactures gas engines for emergency power supply across Asia, to include oil and gas.

The King Abdullah University of Science and Technology (KAUST) will conduct sustainability research, which includes hydrogen, carbon capture and storage, renewables, and more.

Under the Small Business Innovation Research (SBIR) contract, Hyliion will develop and demonstrate an Unmanned Surface Vessel (USV) modular generator concept.

Test data from NASA’s Stennis Space Center informs the production configuration of the F130 engine’s Critical Design Review (CDR), scheduled for fall 2024.

The carbon-free, solid-oxide hydrogen fuel cell produces electricity through direct electrochemical conversion, emitting less environmental pollutants than combustion technology.

The LNG deliveries are subject to a positive final investment decision (FID) for the second train at Cheniere’s Sabine Pass Liquefaction Expansion Project.

Under a long-term service agreement with PETROS, Mitsubishi Power will ensure the power plant’s stable performance following commercial operation.

The Appalachian Regional Clean Hydrogen Hub (ARCH2) will produce hydrogen to decarbonize hard-to-abate industries, such as manufacturing and transportation.

The electrolysis system deploys proton exchange membrane (PEM) technology, which uses electricity to split water into its components: hydrogen and oxygen.

The artificial intelligence platform (AIP) combines siloed and disconnected data sources, logic assets, and systems of action to optimize organizational decision-making.

In addition to an improved flying range and reduced noise, the Trent XWB-84 engine has a 15% fuel-consumption advantage over first-generation Trent units.

The KARNO generator can use various fuels, including hydrogen, natural gas, biogas, and propane, utilizing a linear architecture to produce electricity with lower maintenance costs.

Approximately $100 million will be invested in the Yazoo City Complex to build a CO2 dehydration and compression unit, complementing its ammonia production process.

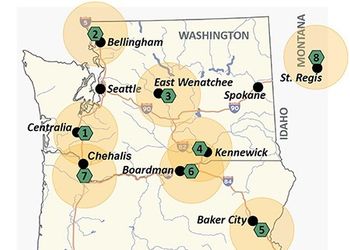

The Pacific Northwest Hydrogen Association (PNWH2) will have eight nodes across Washington, Oregon, and Montana, leveraging technology and renewable energy to decarbonize the industry.

The company’s methane pyrolysis method generates clean hydrogen at point-of-use, eliminating hydrogen transportation and CO2 storage to optimize industrial decarbonization.

In a series of recent aviation deals, Rolls-Royce agreed to deliver 14 Trent 7000 aircraft engines and signed TotalCare and SelectCare agreements with JSX and Vietjet.

Testing will demonstrate the technology integration required for 100% hydrogen fuel operation on Rolls-Royce’s modified Pearl 15 engine.

The facilities in Georgia and North Carolina will produce industrial gases, including liquid oxygen, liquid nitrogen, and liquid argon to supply growing regional markets.

Air Products Qudra’s Blue Hydrogen Industrial Gases Co. (BHIG) generates low-carbon hydrogen while capturing and storing CO2 emissions.

ETN Global’s Scientific Officer, Giuseppe Tilocca, talks about the association’s recent report on decentralized energy systems—their advantages and challenges, trends, and where and how gas turbines fit in.

Cryocap LQ technology is compact and uses a chemical-free, non-flammable process, enabling heat recovery and reuse to supply the district heating network.