Guangdong Energy Group (GEG) will add up to 1.34 GW of grid electricity and industrial process steam for a chemical complex in Huizhou, north of Hong Kong.

Guangdong Energy Group (GEG) will add up to 1.34 GW of grid electricity and industrial process steam for a chemical complex in Huizhou, north of Hong Kong.

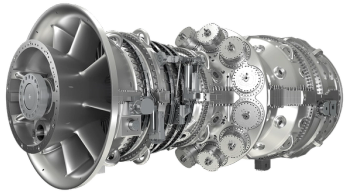

Top OEMs share progress made on new combustion systems for newly manufactured gas turbines and technology retrofits for existing fleets of gas turbines while the DOE shares updates on the regional hydrogen hubs.

The hydrogen-ready gas turbine will be installed at the Jafurah Cogeneration Independent Steam and Power Plant (ISPP).

The July/August 2024 issue offers comprehensive coverage on industrial and aeroderivative gas turbines, steam, and hydro turbines.

Part of Baker Hughes’ Panametrics product line, the measurement sensor solutions can be deployed across industries including hydrogen, oil and gas, power generation, and more.

Flexibility and turbine advancements were the focal point of Wednesday’s panel.

Phoenix project participants will develop components such as the injection system, piston group, ignition system, and a new lubricant for the hydrogen engine.

The Texas-based hydrogen production facility is expected to produce 1 billion cubic feet of low-carbon hydrogen daily and more than 1 million tons of ammonia per year.

Day two of Turbo Expo 2024 discusses how lower-carbon fuels, gas turbines, fuel-flexible advancements, electrolyzers, and more work together for a sustainable energy future.

Eight gas turbines will be delivered to the Taiba 1 and Qassim 1 power plants, which are expected to deliver up to 3.8 GW of electricity to the national grid.

ASME's European Turbomachinery Technical Conference & Exposition is expecting 2,500 attendees and more than 100 exhibitors from 22 countries.

The project will include carbon capture in the north of France, transportation via pipeline to a new liquefaction terminal, and export to storage sites in the North Sea.

As part of a memorandum of understanding (MoU), the companies aim to achieve a gas turbine hydrogen co-firing ratio of 20% at an EGAT power plant.

The hydrogen supply will allow TotalEnergies to reduce net greenhouse gas emissions by 40% from its oil and gas operations by the end of the decade.

Turbomachinery operators can prevent leakage at pressure stations and pneumatically operated valves along the length of the compressor by using leak- or loss-free technologies, says NETL.

The partners signed a letter of intent (LOI) to develop an integrated electrolysis solution to produce hydrogen.

The Element complex, located in the Port of Brownsville, TX, recycles and produces low-carbon fuels and hydrogen from high-gravity shale oil.

ACWA Power will install 4 GW of renewable energy units, 2 GW of electrolyzer capacity, and battery storage facilities to generate 200,000 tons of green hydrogen in the first phase.

Torghatten Nord A/S contracted MAN Cryo to design and integrate bunkering systems, hydrogen piping, vent masts, and a hydrogen process plant for two new-build vessels.

With Turbo Expo 2024 in London, held June 24 – 28, on the horizon, we’re looking back at insights from our interview with NETL at last year’s meeting.

In Part 2 of our interview with GE Vernova's John Intile and Shane Long, the two VPs share what their teams are most excited about in light of GE Vernova’s recent spin-off.

The project, co-led by Black & Veatch and the Grand River Dam Authority (GRDA), will install Unit 4 with Mitsubishi Power’s 426 MW J-class simple-cycle combustion turbine.

The ATS consortium received funding to develop a microturbine prototype that uses carbon-neutral fuels in micro-grids.

Ohmium is helping to decarbonize INA’s Rijeka Refinery and further Croatia’s net-zero goals with its proton membrane exchange (PEM) electrolyzers.

JERA aims to not just adapt to the evolving global energy landscape but to set the pace with its three-pillar growth strategy.