Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

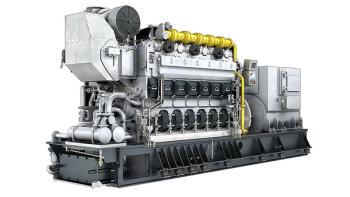

Amogy Combines Ammonia Cracking, Hydrogen Engine to Decarbonize South Korean Market

Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

Christian Kunkel of MAN Energy said ammonia integration in four-stroke internal combustion engines is possible with modified injection systems, but its inherent toxicity presents technical challenges for AmmoniaMot 2.

The studies targeted up to 32% by volume hydrogen blending with natural gas and identified modifications to the power generation assets, including exhaust gas recirculation to lower carbon-capture costs.

The gas turbine market is stable and will remain so among factors such as hydrogen, digitalization, and renewable energy.

Ebara obtained an additional sales base in Uruguay, capitalizing on a growing South American market for pumps in the agricultural, construction, and industrial sectors.

With Safety Integrity Level certification, the XMO2pro analyzer is explosion-proof, flame-proof, and weather-proof with a built-in compact display suitable for tight spaces.

The DCFlex initiative will conduct real-world flexibility demonstrations across data centers and electricity markets to streamline grid integration and manage growing electricity demand.

In addition to the hydrogen-capable 9HA.01 gas turbine, GE Vernova will supply an STF-A650 steam turbine, W88 generator, and heat recovery steam generator for the upcoming Singapore-based plant.

Mitsubishi Gas Chemical will receive ~1 mmtpa of methanol from the Mexican production facility, slated to open in 2028 producing green and blue methanol from natural gas with carbon capture.

Following the licensing agreement, Jiangsu Masada will begin manufacturing MET turbochargers in 2025 with an initial focus on assembly.

Powered by three 9HA.02 gas turbines, the plant will add 2.4 GW to the national grid, reduce fuel consumption and carbon emissions, and advance China’s coal-to-gas energy transition.

Tyler Clifford of Siemens Energy speaks on alternative fuels like methanol, gas turbines, 3D printing, and decarbonizing industrial markets.

The Emirates Central Cooling Systems Corp. (Empower) will supply chilled water for cooling to residential, commercial, healthcare, educational, and multi-use projects.

The plant will convert from cogeneration of heat and electricity to injecting biomethane into the local gas network in Belgium’s Flemish region.

The 2025 Handbook includes a comprehensive outlook of the power industry and gas turbine market as well as an industry-wide directory and specifications listings.

Methanol as an alternative fuel can cut CO2 emissions between 10 – 95% depending on how it’s produced.

Upon completion, the 300-MW floating facility will produce up to 55,000 tons of green hydrogen and nearly 300,000 tons of green ammonia per year.

Koloma leverages its technology, proprietary data, and human capital advantages to discover and commercialize geologic hydrogen resources on a global scale.

With the largest CO2 pipeline network in the United States, ExxonMobil will leverage its infrastructure for the newly leased 271,000-acre offshore storage site.

The final turbine’s construction marks the on-time completion of a project awarded in 2018, featuring two gas turbine combined-cycle (GTCC) plants in Chonburi and Rayong.

The H-class power generation equipment will increase plant efficiency and replace aging conventional assets: three boilers and three steam turbines.

Siemens Energy is developing three technologies—an advanced rotor hydrogen compressor, a Turbo Heater, and a rotating olefins cracker—to drive the energy transition and reduce carbon emissions.

The United States and Brazil will collaborate on various clean-energy initiatives: bioenergy-to-hydrogen, clean energy for remote communities, carbon and methane management, and more.

Related assets, manufacturing capability, and personnel have been transferred to Honeywell, including the coil-wound heat exchanger manufacturing facility in Port Manatee, FL.

At full capacity, the new gigahub will enable the automated series production of PEM stacks with a potential total electrolysis capacity of more than 5 GW per year.