Koloma leverages its technology, proprietary data, and human capital advantages to discover and commercialize geologic hydrogen resources on a global scale.

Koloma leverages its technology, proprietary data, and human capital advantages to discover and commercialize geologic hydrogen resources on a global scale.

With the largest CO2 pipeline network in the United States, ExxonMobil will leverage its infrastructure for the newly leased 271,000-acre offshore storage site.

The final turbine’s construction marks the on-time completion of a project awarded in 2018, featuring two gas turbine combined-cycle (GTCC) plants in Chonburi and Rayong.

The H-class power generation equipment will increase plant efficiency and replace aging conventional assets: three boilers and three steam turbines.

Siemens Energy is developing three technologies—an advanced rotor hydrogen compressor, a Turbo Heater, and a rotating olefins cracker—to drive the energy transition and reduce carbon emissions.

The United States and Brazil will collaborate on various clean-energy initiatives: bioenergy-to-hydrogen, clean energy for remote communities, carbon and methane management, and more.

Related assets, manufacturing capability, and personnel have been transferred to Honeywell, including the coil-wound heat exchanger manufacturing facility in Port Manatee, FL.

At full capacity, the new gigahub will enable the automated series production of PEM stacks with a potential total electrolysis capacity of more than 5 GW per year.

The AE94.3A gas turbine delivers high flexibility, leveraging a ramp rate of 50 MW/min and reaching full load in 26 minutes.

The core equipment was manufactured and tested at Mitsubishi Heavy Industries Compressor Corp.’s facility in Hiroshima, Japan, and was delivered in April 2024.

The first phase capacity of 1.5 million tons of CO2 per year is fully booked, and the joint venture owners are working to further increase the transport and storage capacity.

The AI Assistant—HySAGE—will enable modeling capability and flexibility for incorporating hydrogen codes, standards, and environmental scenarios.

In addition to powering the NH3 Kraken tugboat with green ammonia, Amogy demonstrated this technology in an aerial drone, commercial farm tractor, and semi-truck.

The initial facility will sequester and permanently store 75,000 tons of CO2 per year while generating 5 MW of clean electricity with plans for full-scale operation in 2030.

Ammonia-cracking technology uses catalyst materials to crack ammonia into hydrogen and nitrogen at lower reaction temperatures, reducing heating and maintenance requirements.

Green hydrogen produced through water electrolysis will support the Castellón refinery’s transition to an integrated energy hub.

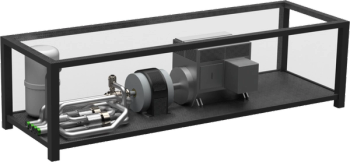

Peru LNG’s assets consist of a natural gas liquefaction plant, a 490-km pipeline, two storage tanks, a marine terminal, and a truck loading facility.

As part of the center’s equipment testing, development, and quality assurance work, liquid hydrogen pumps will be tested with hydrogen at -253°C.

CarbonEdge, leveraging an integrated dashboard, delivers real-time data and CO2 flow alerts across carbon capture, utilization, and storage (CCUS) infrastructure.

The mtu Series 1163 and 8000 engines are now equipped with exhaust gas aftertreatment, which reduces NOx emissions by 75% compared to the previous IMO II limits.

ADNOC will acquire a 35% equity stake in the Baytown facility, which is slated to be the world’s largest, upon startup, low-carbon hydrogen and ammonia production plant.

Small modular reactors (SMRs) and advanced modular reactors (AMRs) benefit from lower investment costs, operational flexibility, and construction modularity.

Using hydrogen-capable H-class technology, the power plant produces up to 60% fewer emissions than plants powered by diesel, coal, and other fossil fuels.

The theme of this year’s show was achievements and needs to unlock a net-zero future in propulsion and power.

With a growing demand for liquefied CO2 carriers with emerging carbon capture and storage (CCS) projects, the partners will build and supply LCO2 carriers for the Japanese market.