“Build Baby Build” has brought about the remake of the energy transition to the energy addition.

“Build Baby Build” has brought about the remake of the energy transition to the energy addition.

The project is subject to Nuclear Regulatory Commission approvals and is the first American reactor to restart after ceasing operations.

CO2-induced corrosion is common in Brazil’s pre-salt fields, where Petrobras reinjects CO2 from its production operations into wells to decrease flaring and boost oil recovery.

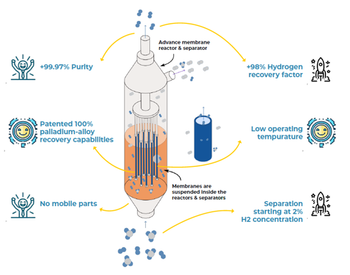

The membrane efficiently separated hydrogen from the natural gas stream, enabling the production of high-purity hydrogen and cleaner streams.

Corpus Christi Liquefaction Stage 3 consists of seven midscale trains, with an expected total production capacity of over 10 MTPA of LNG.

Recently, Chart Industries completed the front-end engineering and design for the nitrogen rejection unit and helium plant.

This ship design satisfies Japan’s port entry restrictions at major power plants and ensures compatibility between ammonia loading/unloading terminals and cargo handling connections.

The Phase 1 expansion will increase total treating capacity to 200 MMcf/d, with plans to increase it further to 400 MMcf/d by 2026.

With engineering, manufacture, and demonstration complete, reliability and safety evaluations will be rendered prior to commercialization and final production.

The 1.2-GW Malaysian plant started commercial operation with GE Vernova’s equipment and control system software.

The NovaLT gas turbine will allow data center customers to adapt and meet their specific, reliable, and sustainable power requirements.

Felix Aschendorf from Siemens Energy says there is one top priority among nuclear developers: reducing construction time and costs.

The delivery of mtu-brand emergency gensets contributes to the European Union’s construction project, which is expected to be finalized in 2025.

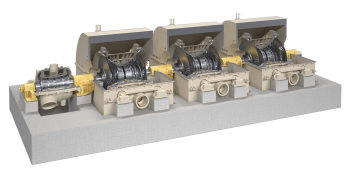

David Valette of MAN Energy Solutions says its Multi Fluid Monitor works in tandem with laboratory oil analysis and traditional detection systems.

Baker Hughes submitted its solution to the Tradewinds Solutions Marketplace and can now develop geothermal plants for baseload power.

The contract represents over 100,000 hours of annual maintenance executed by a 30-person team, so EDF PEI can achieve 95% availability on power assets.

The Sea Dragon will conduct a range of operations, including gas crew changes, drilling support, field-safety standby, emergency towing, and ice management.

Once NextDecade permits, constructs, and operates Trains 6 through 8, the total liquefaction capacity will increase by approximately 18 MTPA.

The acquisition will expand the range of high-performance components, shorten lead times, and offer greater service flexibility for customers in critical industries.

Preparatory construction work is underway next to the Niehl harbour basin, where Rhine water will be extracted to serve as the plant's environmental energy source.

The company plans to tie back the discovery to bp’s operated West Nile Delta Gas Development project, which includes the Raven and El King-2 gas wells.

The Net Power platform will use lessons learned from the development and testing at Net Power’s demonstration facility and the company’s power plant.

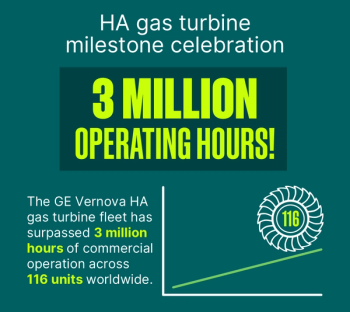

The transition from coal, increased electrification, and rise of AI computational demand may allow the turbine fleet to achieve 10 million hours of cumulative runtime.

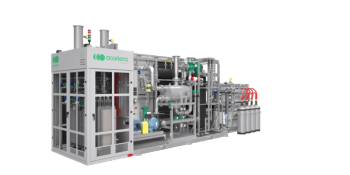

Electrolysis-generated green hydrogen will be converted into e-methane, allowing the fuel to integrate within current natural gas infrastructures.

The issuance to Golden Pass marks the Department of Energy’s third LNG-related approval since the new administration took office, with Commonwealth and JAX LNG certified prior.

The prior administration’s order issued to JAX LNG asserted new oversight for the use of LNG to power marine vessels, also known as LNG bunkering.

The Honeywell Forge software platform will enable the digitalization of Sundyne's equipment, improving reliability and predictive maintenance operations.

This partnership follows the commissioning of GAIL's green hydrogen plant, in which Accelera supplied a 10-MW proton exchange membrane electrolyzer system.

The next-gen engine features two stages of variable stator vanes, cooled high-pressure turbine blades, and additively manufactured components.

The company will deliver CO2 compression and monitoring technologies for the Sweetwater Carbon Storage Hub and gas turbines for power generation applications.