GE Vernova installed advanced gas path upgrades on 9.E gas turbines and MXLII upgrades on 13E2 gas turbines, increasing power output up to 6%.

GE Vernova installed advanced gas path upgrades on 9.E gas turbines and MXLII upgrades on 13E2 gas turbines, increasing power output up to 6%.

Roots Blowers Systems manufactures displacement blowers engineered to deliver a steady volume of air with each rotation.

In his opening keynote, Lorenzo Simonelli, CEO of Baker Hughes, echoed the theme of an “affordable, sustainable, and secure” energy landscape.

The simple-cycle, bio-fueled station will be powered by Ansaldo’s AE94.3A turbine.

Arrow Engine distributes natural gas-powered engines through a global distribution network, with primary focus on the United States and Canada.

During its Annual Meeting, Baker Hughes signed agreements with Eden Geothermal, PETROVIETNAM, Microsoft, and NNPC/FIRST E&P.

The company’s modular capture plant design reduces capital costs, minimizes the impact on existing factory operations, and easily facilitates integration with pulp mills.

At Baker Hughes Annual Meeting 2025, the company announced partnerships to support LNG, ammonia, and offshore greenfield developments.

This year’s theme, Progress at Scale, explores how innovations can drive lasting change in the energy industry.

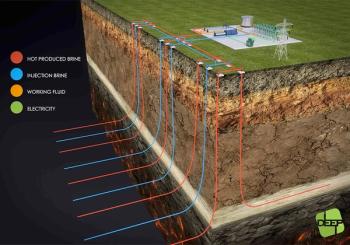

The approach will leverage the natural permeability of the sedimentary rock formation and enable reliable, cost-efficient, and sustainable geothermal energy production.

The next phase of testing will focus on performance and emission optimization, including injection, selective catalytic reduction systems, and control strategies.

The digiPrime pump, anchored by a 3,000 hp Cummins natural gas variable-speed engine, is a direct drive solution with significant thermal efficiency.

The investment will satisfy increasing customer demand, bolster national supply chains, and allow GE Vernova to continue developing its power technologies.

The company completed and commissioned 70 km of gas pipelines and 21 modular compressor units across seven Uzbekistani oilfields.

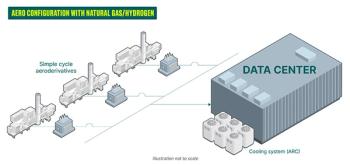

The multi-GW scale power plant, co-located to a data center, will use flexible power to support lower carbon solutions and renewable energy.

The Surface Effect Ships are said to be “the fastest of their kind”, with a high speed of 53 knots.

The carbon-capture plant is expected to capture 350,000 mtpa of CO2 with SLB Capturi’s modularized Just Catch 400 technology.

The acquisition strengthens Shell’s presence in New England and continues its 2019 energy supply agreement, securing long-term energy offtake from RISEC’s plant.

This milestone follows the completion of the Wellhead Pressure Management Project in 2024, designed to optimize the Tengiz oil field and processing plants.

MFM generates an alert and technical recommendations for the operator, preventing further degradation that may cause damage and unplanned shutdowns.

The Netherlands-based plant uses SLB Capturi’s Just Catch modular system, which reduces onsite installation and outfitting work for lower costs and ease-of-deployment.

Cryo-Mach will expand Dover's participation in liquified oxygen, argon, and nitrogen in the industrial gas and transportation markets.

The plant will produce approximately 200 GWh of e-methane for heavy road and maritime transport per year, as well as 180 GWh of CO2-free district heating for Tampere’s system.

The tool has been re-engineered to have a smaller footprint, a better price-point, and testing on angle.

The company will provide long-term turbine maintenance under a 25-year agreement.

Michael Stipa and Aslan Karaismailoglu of Rolls-Royce share how mtu gas-fired gensets help customers operate independently from the national grid.

Users can transition toward measurement-supported methane accountability, improving operational efficiency and safeguarding their market position.

These awards kick off Phase 1 activities and the hubs’ use of energy resources, existing infrastructure, electrolyzers, and more to reduce carbon emissions across heavy industries.

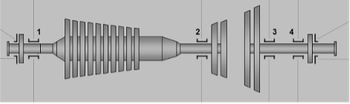

Managers from a gas-treating company investigated the effects of varnish on the vibration of bearing No.2 of a Siemens SGT 600 gas turbine.

The East Texas facility will serve as a buffer to balance natural gas supply and demand, ensuring continuous service during times of peak electricity demand.