Remote monitoring delivers comprehensive plant control/overview, but Tegtmeier says that it shouldn’t replace standard operating procedures, equipment criticality, and other fundamentals.

Remote monitoring delivers comprehensive plant control/overview, but Tegtmeier says that it shouldn’t replace standard operating procedures, equipment criticality, and other fundamentals.

The equipment will support Honeywell’s hydrogen purification system, ammonia processing, and syngas processing, addressing multiple stages of the clean ammonia value chain.

Per the company’s full-year results, the equipment and services of each segment obtained $59.3 billion in orders with approximately +34% organic, year-over-year growth.

The Alternative Technology Demonstration and Research Program obtains data from propane-fired combined heat and power installations and commercial facilities in the United States.

The permit authorizes construction and operation under state and federal air-quality requirements, closing the project’s permitting process with a major regulatory milestone.

The company installed its own ammonia vaporization system at the German Aerospace Center to enable partial- and full-load testing, helping to validate the new combustor’s architecture.

Prior to its designation as a reserve power source, the Birr test facility validated advanced gas turbine technologies and drove performance, emissions, and fuel flexibility improvements.

Daniel Tegtmeier, Director of EthosEnergy’s Performance Center, says that the energy transition shifted its focus from decarbonization and renewables to extending current assets.

The initial research collaboration, forged in 2020, focused on next-generation clean energy solutions and analyzed large-scale data volumes from Indonesian power plants.

The Propane Education & Research Council said that propane’s speed-to-power, extensive infrastructure, and readily available power equipment makes it a prime first-energy choice.

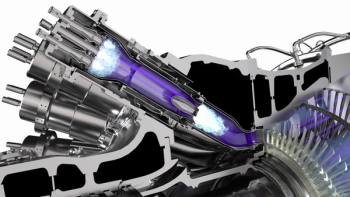

The company’s aftermarket combustor technology, FlameSheet and the MicroMixer, successfully demonstrated low NOx emissions and reliable flame stabilization with cracked ammonia.

The ACES Delta project uses hydrogen production, salt cavern storage, and gas turbines to deliver dispatchable power to California while supporting long-term decarbonization goals.

At POWERGEN International 2026, EPRI’s Stephen Storm covers several proactive approaches to manage flexible operations and performance for gas turbine-driven thermal plants.

The keynote highlighted how data center growth, rising electricity loads, and infrastructure constraints are accelerating changes across generation, transmission, and resource planning.

The final investment decision will boost production capacity at the Eastern Mediterranean project, supporting regional energy supply later this decade.

The agreement covers 1 MTPA of LNG and marks a key step toward financing and a final investment decision targeted for early 2026.

The Turbomachinery News Network, for the week of January 12, 2026, covers news from Ansaldo Energia, Duke Energy, Babcock & Wilcox, Oglethorpe Power, and Arabelle Solutions.

The compressor trains will perform two process duties—flash-gas compression and high-pressure gas injection—maintaining maximum production in Brazil’s Orca field.

The M701 JAC gas turbine features a flexible operating profile and hydrogen co-firing capability, playing a critical role in stabilizing Qatar’s electricity power grid.

Each half-speed steam turbine, featuring improved cycle efficiency, will be coupled to a hydrogen and water-cooled GIGATOP 4-pole generator synchronized to the 50-Hz Polish grid.

Once operational, the combined-cycle facility will support long-term, system-wide load growth for homes, businesses, and existing industries across Monroe County, GA.

The acquisition provides MIRATECH with increased catalyst production capacity, supporting growth across power generation, gas compression, and industrial/OEM applications.

Per Klaus Brun and Rainer Kurz, properly executed scheduled and condition-based maintenance methods are adequate to prevent failures, costly shutdowns, and interventions.

The FLEX4H2 technology uses the company’s Constant Pressure Sequential Combustion system, which burns fuel across two stages and allows independent control, lower emissions, and more.

Electrolyzer-derived green hydrogen will be stored and, when demand is highest, used in a combustion turbine equipped with GE Vernova’s hydrogen co-firing technology.

Additionally, Glenfarne and Donlin will jointly establish a method to develop and construct an approximately 315-mile-long natural gas pipeline from southcentral to southwest Alaska.

The Turbomachinery News Network, for the week of January 5, 2026, covers news from GE Vernova, Mitsubishi Power, Woodside Energy, Kawasaki, and Intensity Infrastructure.

The Applied Digital AI Factory project uses a proven plant configuration: A gas-fired boiler generates heat and steam to drive the turbines, producing reliable and dispatchable energy.

The system’s combined heat and power configuration supports a pyrolysis thermochemical reaction, which converts swine waste into biogas in a closed-loop design.

The acquisition broadens Encore Oilfield Services’ physical footprint with two 80-ton overhead cranes, 70-foot eave heights, and 103,000-square-feet of manufacturing space.