The contracts open the door for lower-carbon chemicals exports and the development of storage facilities, tank-to-jetty pipelines, inter-site pipelines, and liquid product storage.

The contracts open the door for lower-carbon chemicals exports and the development of storage facilities, tank-to-jetty pipelines, inter-site pipelines, and liquid product storage.

EthosEnergy will replace exhaust systems and additional auxiliary equipment on Trapani Unit 1 at the historic Sicilian plant.

United Aerospace Maintenance Co. will fulfill the customers’ CFM LEAP maintenance needs in Europe, the Middle East, and Africa by conducting on-wing-support and near-wing retrofits.

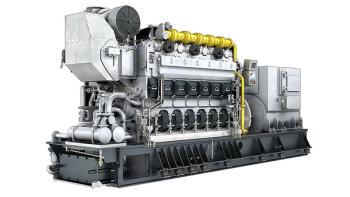

The generator sets will be deployed at five distributed energy sites across Alberta, providing power to the grid during times of peak electrical demand.

Jeremee Wetherby, the Carbon Solutions Director at GE Vernova, offers deeper insights into the benefits of retrofitting carbon-capture systems with an exhaust gas recirculation system.

HD Hyundai Infracore, SK Innovation, and Amogy will explore the long-term commercial viability of their combined ammonia-to-power generation system.

GE Vernova signed a maintenance contract and installed two 7HA.02 gas turbines, one STF-D600 steam turbine, two heat recovery steam generators, and three H65 generators.

Under the joint venture, GLJ will provide consulting services, resource evaluation, and emissions management, and Energy Fuse will contribute its experience in geoscience and engineering.

Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

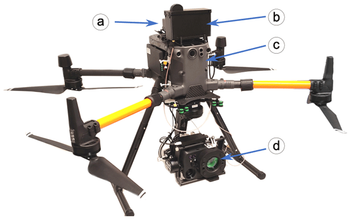

The AI-assisted borescope inspection technology raised model recall rates by 33.6% and increased model precision rates by 13.5% compared to the previous Gas Power-assist model.

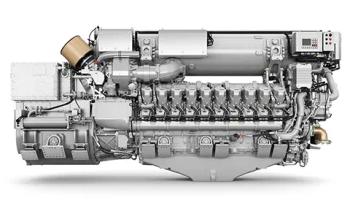

Christian Kunkel of MAN Energy said ammonia integration in four-stroke internal combustion engines is possible with modified injection systems, but its inherent toxicity presents technical challenges for AmmoniaMot 2.

The studies targeted up to 32% by volume hydrogen blending with natural gas and identified modifications to the power generation assets, including exhaust gas recirculation to lower carbon-capture costs.

Ebara obtained an additional sales base in Uruguay, capitalizing on a growing South American market for pumps in the agricultural, construction, and industrial sectors.

With Safety Integrity Level certification, the XMO2pro analyzer is explosion-proof, flame-proof, and weather-proof with a built-in compact display suitable for tight spaces.

Investments include an additional horizontal boring mill, a commutator repair system, and expanding the Wyoming shop’s footprint with a new test stand and 40-ton crane.

Leveraging data from its quantification, monitoring, reporting, and verification projects, Cheniere’s new methane target is 0.03% per ton of LNG produced at two liquefaction facilities.

The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

With future submarines expected to require increased electrical power, the mtu charging unit and NautIQ automation system will enable higher power output and integrated control, respectively.

The DCFlex initiative will conduct real-world flexibility demonstrations across data centers and electricity markets to streamline grid integration and manage growing electricity demand.

In addition to HA combined-cycle equipment, GE Vernova signed a 12-year service agreement to manage the project lifecycle, training, and maintenance at the Gryfino Dolna Odra plant.

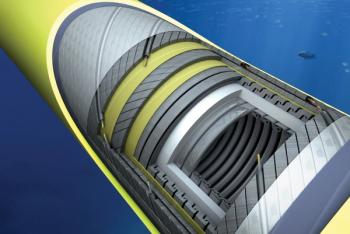

Petrobras signed contracts with Baker Hughes for risers and flowlines for hydrocarbon production and gas and water injection; and support for equipment storage, maintenance, and installation.

In addition to the hydrogen-capable 9HA.01 gas turbine, GE Vernova will supply an STF-A650 steam turbine, W88 generator, and heat recovery steam generator for the upcoming Singapore-based plant.

Mitsubishi Gas Chemical will receive ~1 mmtpa of methanol from the Mexican production facility, slated to open in 2028 producing green and blue methanol from natural gas with carbon capture.

Peru LNG owns and operates the only LNG export facility in South America, consisting of a natural gas liquefaction plant, pipeline, storage tanks, and additional assets.

Following the licensing agreement, Jiangsu Masada will begin manufacturing MET turbochargers in 2025 with an initial focus on assembly.

Supported by the European Innovation Fund (EIF), ACCSION will receive €220M and, using its Cryocap technology, will capture, purify, and liquefy approximately 95% of the CO2 emitted by the cement kilns at the Denmark plant.

Powered by three 9HA.02 gas turbines, the plant will add 2.4 GW to the national grid, reduce fuel consumption and carbon emissions, and advance China’s coal-to-gas energy transition.

Koch-Glitsch will deliver proprietary separation equipment for ION’s post-combustion carbon-capture projects, increasing performance while minimizing cost and physical footprint.

The investment will fund additional engine test cells and new equipment and technology, including AI-enabled inspection techniques.

The Gillis Treating Plant will treat off-spec natural gas with services such as CO2 amine treating, gas dehydration, CO2 compression, and related utility and power systems.