Sixteen gas engines will be installed across two power plants and an LNG terminal in East Malaysia and Indonesia.

Sixteen gas engines will be installed across two power plants and an LNG terminal in East Malaysia and Indonesia.

ADNOC will acquire a 35% equity stake in the Baytown facility, which is slated to be the world’s largest, upon startup, low-carbon hydrogen and ammonia production plant.

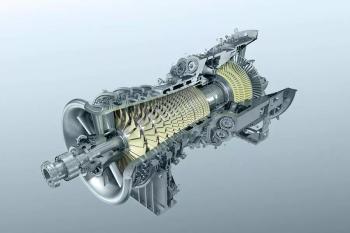

General Electric Saudi Advanced Turbines (GESAT) manufactures and supplies gas turbines for power generation plants in up to 10 countries, including Saudi Arabia.

In addition to Fast LNG’s Free Trade Agreement authorization from the Department of Energy (DOE), the asset can now export LNG to global customers and markets.

The high-pressure centrifugal pump is hermetically sealed and designed with a magnetic coupling that aids torque transmission from the motor.

Small modular reactors (SMRs) and advanced modular reactors (AMRs) benefit from lower investment costs, operational flexibility, and construction modularity.

The company will study and deploy advanced drilling, completion, and production technologies during future development phases at the Tahiti and Jack/St. Malo facilities.

Using hydrogen-capable H-class technology, the power plant produces up to 60% fewer emissions than plants powered by diesel, coal, and other fossil fuels.

Systems with Intelligence (SWI) will integrate its fixed infrared sensors with GE Vernova’s DGA 900 Plus—an early-detection gas transformer monitoring system.

With a growing demand for liquefied CO2 carriers with emerging carbon capture and storage (CCS) projects, the partners will build and supply LCO2 carriers for the Japanese market.

EthosEnergy employs 3,600 individuals across three subdivisions: optimized solutions, operations and maintenance, and aerospace and defense MRO.

The ME-GI models are two-stroke propulsion engines operating on RoRo vessels, PCTCs, container vessels, bulk carriers, tankers, and LNG carriers.

The agreement builds on a previous long-term LNG sale and purchase agreement (SPA), aiding bilateral trade between the states of Qatar and Kuwait.

The JAC gas turbine is hydrogen-ready with more than 64% efficiency rate, providing the plant with flexibility, faster start-up times, and load-following capabilities.

In addition to Piñon’s two acid gas injection wells in the Delaware Basin, Enterprise will evaluate a third location to support up to 750 MMcf/d in total treating capacity.

The R3000 control panel is equipped with remote monitoring capabilities, offering a comprehensive data dashboard and customized reports to ensure reliable compressor operation.

Chevron will hold a 70% participating interest; Woodside Energy will hold a 30% stake; GS Caltex will potentially own a 5% interest upon regulatory approvals.

The Polish Ministry of National Defense will obtain a full engine depot and engine training capabilities, ensuring supply security for platforms using T700/CT7 engines.

Federal investment allows manufacturers to produce additional residential heat pumps, residential heat pump water heaters, school heat pumps, and heat pump compressors.

To support the 2050 carbon-neutrality plan, Taiwan Fertilizer Co. (TFC) will use blue and green ammonia as fuel in Taiwan.

The composite tubing can reduce the chill-down time, hydrogen boil-off, and the dry mass of cryogenic fluid transfer lines.

The two companies are expanding their joint venture, MTU Yuchai Power, which manufactures gas engines for emergency power supply across Asia, to include oil and gas.

The geopressured geothermal system (GGS) facility will store energy for 6-to-10-hour durations with a round-trip efficiency (RTE) of 70-75% and water losses less than 2%.

The King Abdullah University of Science and Technology (KAUST) will conduct sustainability research, which includes hydrogen, carbon capture and storage, renewables, and more.

The Anchor floating production unit (FPU) is an all-electric facility with electric motors and electronic controls to reduce carbon emissions.

The Sutter Decarbonization Project utilizes carbon-capture technology with high-capture efficiency, solvent stability, low emissions, and low energy use.

Under the Small Business Innovation Research (SBIR) contract, Hyliion will develop and demonstrate an Unmanned Surface Vessel (USV) modular generator concept.

During testing at the National Carbon Capture Center (NCCC), FrostCC successfully captured CO2 and co-pollutants from flue gas.

Test data from NASA’s Stennis Space Center informs the production configuration of the F130 engine’s Critical Design Review (CDR), scheduled for fall 2024.

The carbon-free, solid-oxide hydrogen fuel cell produces electricity through direct electrochemical conversion, emitting less environmental pollutants than combustion technology.