A 35-MW steam pump system at Vicinity’s Kendall Station will use thermal energy from the Charles River to produce high-pressure steam and lower fossil fuel emissions.

A 35-MW steam pump system at Vicinity’s Kendall Station will use thermal energy from the Charles River to produce high-pressure steam and lower fossil fuel emissions.

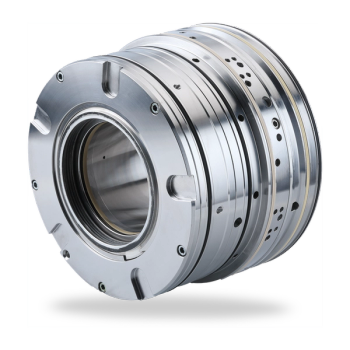

EthosEnergy will join its seal system design, project management, and compressor maintenance with EagleBurgmann’s industrial sealing technology to support customer needs.

MAN Energy Solutions will provide eight 18V51/60 engines and its after-sales brand will provide spare parts, technical services, and more over 25 years.

The CO2-based seawater heat pump operates with a wood chip boiler and electric boiler plant to provide heat year-round.

EthosEnergy’s turbine workshop and Performance Center work hand-in-hand to maintain operators’ turbine equipment and provide remote operations and monitoring.

Dominion Energy is updating the South Carolina-based hydro plant to boost its longevity and performance and better maintain water quality.

The expansions include six compressor overhaul stations, two drive-through loading bays, an extruder overhaul station, and additional storage and maintenance spaces.

The high-precision, non-contact displacement sensors complement condition monitoring systems by measuring and monitoring runout, speed, and changes in machine vibration profiles.

When deciding to refurbish or renew, gas turbine plant owners have to weigh engineering and economic factors, including the turbine’s footprint.

Warwood delivers electric motor and gearbox repair, sales, and field services that focus on coal, steel, shale, and industrial customers in the Appalachian region.

The November/December 2024 issue highlights emerging decarbonization efforts that integrate hydrogen, ammonia, and new technologies into increasingly intermittent grids.

DOE awarded GE Aerospace, Boeing, and NASA supercomputer access to study open-fan aerodynamics to reduce drag and improve fuel efficiency.

A compressor’s seal system is the culprit of most common unscheduled shutdowns.

To capture and reinject natural gas into oil reservoirs, Air Source One uses rotary screw compressors, an integrated heater, and a ventilation system.

GE Aerospace’s lean operating model and overall industry growth have spurred investments by standardizing processes and fostering operational efficiency and reliability.

The SolveBright scrubbing system—to be installed at Mälarenergi AB’s waste-to-energy plant—is a post-combustion carbon-capture technology that absorbs CO2 from flue gas.

EthosEnergy will replace exhaust systems and additional auxiliary equipment on Trapani Unit 1 at the historic Sicilian plant.

United Aerospace Maintenance Co. will fulfill the customers’ CFM LEAP maintenance needs in Europe, the Middle East, and Africa by conducting on-wing-support and near-wing retrofits.

GE Vernova signed a maintenance contract and installed two 7HA.02 gas turbines, one STF-D600 steam turbine, two heat recovery steam generators, and three H65 generators.

The AI-assisted borescope inspection technology raised model recall rates by 33.6% and increased model precision rates by 13.5% compared to the previous Gas Power-assist model.

The gas turbine market is stable and will remain so among factors such as hydrogen, digitalization, and renewable energy.

Investments include an additional horizontal boring mill, a commutator repair system, and expanding the Wyoming shop’s footprint with a new test stand and 40-ton crane.

The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

In addition to HA combined-cycle equipment, GE Vernova signed a 12-year service agreement to manage the project lifecycle, training, and maintenance at the Gryfino Dolna Odra plant.

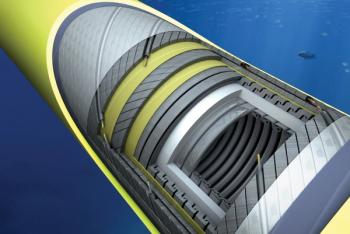

Petrobras signed contracts with Baker Hughes for risers and flowlines for hydrocarbon production and gas and water injection; and support for equipment storage, maintenance, and installation.