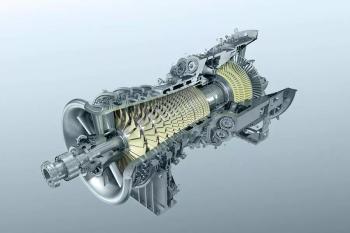

EthosEnergy’s Engineering Manager Philip Booth discusses available technology in reverse engineering for rotating equipment.

EthosEnergy’s Engineering Manager Philip Booth discusses available technology in reverse engineering for rotating equipment.

Blading Services Unlimited (BSU), an aftermarket manufacturer, focuses on producing new blading for all models of gas turbines, steam turbines, and compressors.

Phase 1 advanced gas path (AGP) upgrades can increase the Besmaya power plant’s output by 6%, as well as improve fuel consumption and extend asset lifespan.

The final turbine’s construction marks the on-time completion of a project awarded in 2018, featuring two gas turbine combined-cycle (GTCC) plants in Chonburi and Rayong.

On our Turbo Tour of EthosEnergy, Engineering Manager Philip Booth spoke about the repair, overhaul, and aftermarket markets.

The 10 integrated compressor line (ICL) units will be installed and increase energy capacity at the Margham gas storage facility in Dubai.

Turbocompressors with side streams are operated with tight tolerances on operational parameters compared to conventional compressors.

In this episode of the TurboTime podcast, Daniel Tegtmeier, Director of EthosEnergy’s Performance Center, talks about remote operations and monitoring.

The company acquired APSCO, a hydraulic and pneumatic provider; Blutek, a compressed air and nitrogen generation solutions designer; and UT Pumps, a screw and plunger pump manufacturer.

AI Wingmate provides GE Aerospace employees with an internal platform for instant information access, faster learning and discovery, and advanced support tools.

Modernization options for ammonia syngas trains can meet a wide range of plant requirements for uptime, efficiency, costs, and footprint.

The first phase capacity of 1.5 million tons of CO2 per year is fully booked, and the joint venture owners are working to further increase the transport and storage capacity.

The VS6 sensor features a cold-start suppression function, a protection class of IP67, and is compatible with most Eaton hydraulic filtration systems.

The agreement reorganizes the cooperation, accelerates processes, simplifies procedures, and defines common standards for yacht engines and propulsion systems overhauls.

The company’s local team will repair capital parts, supply spare parts, and provide turnkey on-site services in France and its overseas territories.

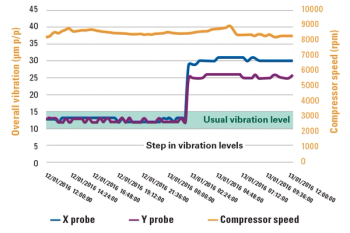

Machine learning techniques offer real-time anomaly detection that proactively identifies potential failures in turbomachinery.

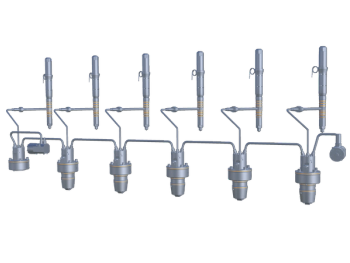

Initially installed on the MAN 49/60DF engine, the fuel-injection system comprises a uniform high-pressure pump, a newly developed injector, and the CR 1.6 valve group.

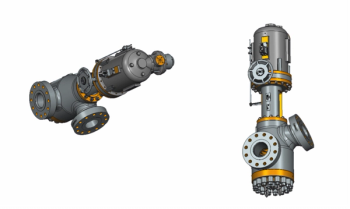

The high-pressure centrifugal pump is hermetically sealed and designed with a magnetic coupling that aids torque transmission from the motor.

Using hydrogen-capable H-class technology, the power plant produces up to 60% fewer emissions than plants powered by diesel, coal, and other fossil fuels.

Systems with Intelligence (SWI) will integrate its fixed infrared sensors with GE Vernova’s DGA 900 Plus—an early-detection gas transformer monitoring system.

EthosEnergy employs 3,600 individuals across three subdivisions: optimized solutions, operations and maintenance, and aerospace and defense MRO.

The September/October 2024 issue highlights the dynamic shifts in the global LNG market that are affecting exports, production, capacity growth, and more.

The JAC gas turbine is hydrogen-ready with more than 64% efficiency rate, providing the plant with flexibility, faster start-up times, and load-following capabilities.

The R3000 control panel is equipped with remote monitoring capabilities, offering a comprehensive data dashboard and customized reports to ensure reliable compressor operation.

Session speakers offer an analysis of gas turbines, including their working principles, thermodynamics, condition monitoring and maintenance, and bottom-cycle performance.