The Honeywell Forge software platform will enable the digitalization of Sundyne's equipment, improving reliability and predictive maintenance operations.

The Honeywell Forge software platform will enable the digitalization of Sundyne's equipment, improving reliability and predictive maintenance operations.

Scott DeNeale of Oak Ridge National Lab shares trends in hydropower—from modular designs to additive-manufactured Francis turbines.

Initially, the venture will advance four natural gas, combined-cycle power plant projects totaling over 5 GW in the ERCOT & PJM markets.

The contract’s wider resource opportunity across Kirkuk and the surrounding area is projected to include up to 20 billion barrels of oil equivalent.

Combining 3D laser scanning and generative AI automates inspection processes, enhances service quality, and expedites equipment overhauls.

The M701 JAC gas turbine represents the first deployment of this technology in a Middle Eastern aluminum smelter, contributing to Aluminum Bahrain’s decarbonization goals.

OEMs are using AI- and ML-equipped software and control systems to improve data quality and reliability, automate tasks, monitor assets, assist smaller crews, and make predictive maintenance commonplace.

Billy Sanez, Director of Global Marketing at SpotSee, addresses the risks of aerospace component transportation and how asset condition monitoring may help.

Once operational, the plant's two gas turbines will generate a combined 990 MW, representing nearly 7% of Morocco's national grid capacity.

Megan Reusser of Burns & McDonnell said mechanical, thermal, electrochemical, and chemical LDES could help reduce the need for grid expansion, but each has its challenges.

Paul DiMascio of ProEnergy discusses how direct ammonia injection systems simplify NOx and CO removal.

Ansaldo will design, supply, commission, maintain, and service its five 250-MVAR synchronous condensers.

INEOS, Royal Wagenborg, and Royal Niestern Sander shipyard will develop a liquefied CO2 carrier, expected to enter service by year-end 2025.

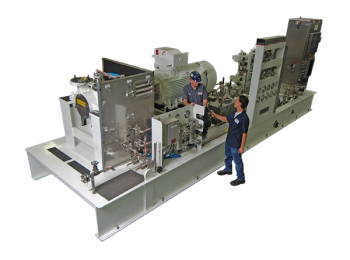

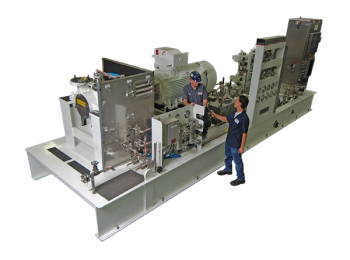

The company will deliver gas compression trains, propane compressors, liquefaction trains, and a power island to the Jafurah Gas Field and Plaquemines LNG.

The January/February 2025 issue gives readers an update on software and controls under the lens of AI and ML, the digitalization of compressor maintenance, and more.

GE Vernova installed advanced gas path upgrades on 9.E gas turbines and MXLII upgrades on 13E2 gas turbines, increasing power output up to 6%.

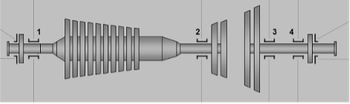

Roots Blowers Systems manufactures displacement blowers engineered to deliver a steady volume of air with each rotation.

In his opening keynote, Lorenzo Simonelli, CEO of Baker Hughes, echoed the theme of an “affordable, sustainable, and secure” energy landscape.

The digiPrime pump, anchored by a 3,000 hp Cummins natural gas variable-speed engine, is a direct drive solution with significant thermal efficiency.

The Surface Effect Ships are said to be “the fastest of their kind”, with a high speed of 53 knots.

This milestone follows the completion of the Wellhead Pressure Management Project in 2024, designed to optimize the Tengiz oil field and processing plants.

MFM generates an alert and technical recommendations for the operator, preventing further degradation that may cause damage and unplanned shutdowns.

The company will provide long-term turbine maintenance under a 25-year agreement.

Michael Stipa and Aslan Karaismailoglu of Rolls-Royce share how mtu gas-fired gensets help customers operate independently from the national grid.

Managers from a gas-treating company investigated the effects of varnish on the vibration of bearing No.2 of a Siemens SGT 600 gas turbine.