The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

In addition to HA combined-cycle equipment, GE Vernova signed a 12-year service agreement to manage the project lifecycle, training, and maintenance at the Gryfino Dolna Odra plant.

In addition to the hydrogen-capable 9HA.01 gas turbine, GE Vernova will supply an STF-A650 steam turbine, W88 generator, and heat recovery steam generator for the upcoming Singapore-based plant.

Powered by three 9HA.02 gas turbines, the plant will add 2.4 GW to the national grid, reduce fuel consumption and carbon emissions, and advance China’s coal-to-gas energy transition.

TPS 2024 tackled the latest challenges, solutions, and technologies in the turbomachinery industry.

John Bartos, CEO of RMS, says acquiring precision engineering, advanced metrology, and more allows the company to provide end-to-end solutions.

The 2025 Handbook includes a comprehensive outlook of the power industry and gas turbine market as well as an industry-wide directory and specifications listings.

Mitsubishi Heavy Industries built and supplied main power-generating equipment, including the steam turbines, circulating fluidized bed boiler, and more.

Integrating an exhaust gas recirculation system reduces the cost and footprint of a carbon-capture system and lowers operating costs.

Blading Services Unlimited (BSU), an aftermarket manufacturer, focuses on producing new blading for all models of gas turbines, steam turbines, and compressors.

The final turbine’s construction marks the on-time completion of a project awarded in 2018, featuring two gas turbine combined-cycle (GTCC) plants in Chonburi and Rayong.

The H-class power generation equipment will increase plant efficiency and replace aging conventional assets: three boilers and three steam turbines.

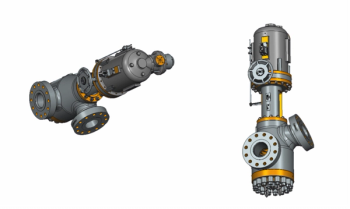

Turbocompressors with side streams are operated with tight tolerances on operational parameters compared to conventional compressors.

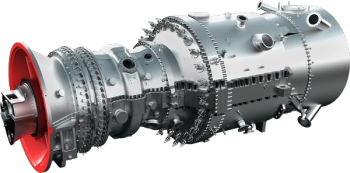

The AE94.3A gas turbine delivers high flexibility, leveraging a ramp rate of 50 MW/min and reaching full load in 26 minutes.

Modernization options for ammonia syngas trains can meet a wide range of plant requirements for uptime, efficiency, costs, and footprint.

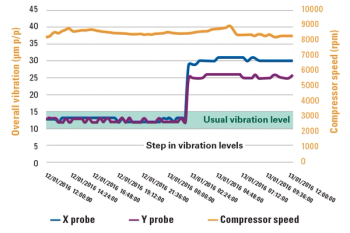

Machine learning techniques offer real-time anomaly detection that proactively identifies potential failures in turbomachinery.

Using hydrogen-capable H-class technology, the power plant produces up to 60% fewer emissions than plants powered by diesel, coal, and other fossil fuels.

The September/October 2024 issue highlights the dynamic shifts in the global LNG market that are affecting exports, production, capacity growth, and more.

The JAC gas turbine is hydrogen-ready with more than 64% efficiency rate, providing the plant with flexibility, faster start-up times, and load-following capabilities.

At TPS 2024, Klaus Brun of Ebara Elliott addresses the company’s rebranding, prominent industry challenges, and upcoming products for sustainability and green energy.

Session speakers offer an analysis of gas turbines, including their working principles, thermodynamics, condition monitoring and maintenance, and bottom-cycle performance.

A steam turbine’s control system should ensure stable operation throughout each phase: start-up, shutdown, and parallel operation.

Under a long-term service agreement with PETROS, Mitsubishi Power will ensure the power plant’s stable performance following commercial operation.

Implementing phased array ultrasonic testing (PAUT) in turbine inspection and maintenance marks an evolution from traditional maintenance to more advanced solutions that ensure efficiency and reliability.

The power generation equipment will be installed at a simple-cycle power plant to boost the operational stability of Ireland’s power system.