The plant will convert from cogeneration of heat and electricity to injecting biomethane into the local gas network in Belgium’s Flemish region.

The plant will convert from cogeneration of heat and electricity to injecting biomethane into the local gas network in Belgium’s Flemish region.

Upon completion, the 300-MW floating facility will produce up to 55,000 tons of green hydrogen and nearly 300,000 tons of green ammonia per year.

Koloma leverages its technology, proprietary data, and human capital advantages to discover and commercialize geologic hydrogen resources on a global scale.

Mitsubishi Heavy Industries built and supplied main power-generating equipment, including the steam turbines, circulating fluidized bed boiler, and more.

EthosEnergy’s Engineering Manager Philip Booth discusses available technology in reverse engineering for rotating equipment.

Blading Services Unlimited (BSU), an aftermarket manufacturer, focuses on producing new blading for all models of gas turbines, steam turbines, and compressors.

With the largest CO2 pipeline network in the United States, ExxonMobil will leverage its infrastructure for the newly leased 271,000-acre offshore storage site.

Phase 1 advanced gas path (AGP) upgrades can increase the Besmaya power plant’s output by 6%, as well as improve fuel consumption and extend asset lifespan.

Woodside Louisiana LNG, formerly the Driftwood LNG development opportunity, is an under-construction LNG production and export terminal with 27.6 MTPA permitted capacity.

The final turbine’s construction marks the on-time completion of a project awarded in 2018, featuring two gas turbine combined-cycle (GTCC) plants in Chonburi and Rayong.

On our Turbo Tour of EthosEnergy, Engineering Manager Philip Booth spoke about the repair, overhaul, and aftermarket markets.

The 10 integrated compressor line (ICL) units will be installed and increase energy capacity at the Margham gas storage facility in Dubai.

The H-class power generation equipment will increase plant efficiency and replace aging conventional assets: three boilers and three steam turbines.

Operated and non-operated interests in the Athabasca Oil Sands Project (AOSP) and Duvernay shale will be sold to Canadian Natural Resources in a $6.5 billion all-cash transaction.

The United States and Brazil will collaborate on various clean-energy initiatives: bioenergy-to-hydrogen, clean energy for remote communities, carbon and methane management, and more.

Related assets, manufacturing capability, and personnel have been transferred to Honeywell, including the coil-wound heat exchanger manufacturing facility in Port Manatee, FL.

The system will feature power-conversion technologies, including propulsion-load electric motors, E-houses, power electronic motor drives, load banks, transformers, and more.

In this episode of the TurboTime podcast, Daniel Tegtmeier, Director of EthosEnergy’s Performance Center, talks about remote operations and monitoring.

At full capacity, the new gigahub will enable the automated series production of PEM stacks with a potential total electrolysis capacity of more than 5 GW per year.

The company acquired APSCO, a hydraulic and pneumatic provider; Blutek, a compressed air and nitrogen generation solutions designer; and UT Pumps, a screw and plunger pump manufacturer.

The AE94.3A gas turbine delivers high flexibility, leveraging a ramp rate of 50 MW/min and reaching full load in 26 minutes.

The completion follows Woodside’s agreement to acquire OCI Clean Ammonia’s 1.1 MTPA Clean Ammonia Project, which is currently under construction with production planned for 2025.

AI Wingmate provides GE Aerospace employees with an internal platform for instant information access, faster learning and discovery, and advanced support tools.

The core equipment was manufactured and tested at Mitsubishi Heavy Industries Compressor Corp.’s facility in Hiroshima, Japan, and was delivered in April 2024.

The anaerobic digester at Synthica San Antonio will transform waste into renewable energy while removing methane and CO2 from the atmosphere.

The first phase capacity of 1.5 million tons of CO2 per year is fully booked, and the joint venture owners are working to further increase the transport and storage capacity.

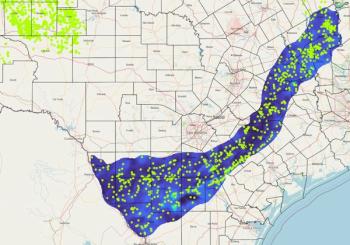

Marubeni will provide technical and financial assistance for Ozona to identify and acquire pore space, permit sequestration wells, and establish facilities and pipelines in Texas.

The AI Assistant—HySAGE—will enable modeling capability and flexibility for incorporating hydrogen codes, standards, and environmental scenarios.

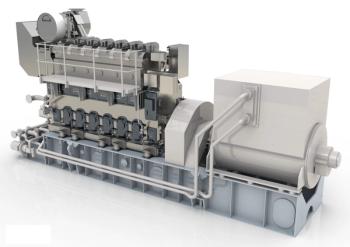

Two Arctic offshore patrol ships will be equipped with 6L32/44CR engines, common-rail electronic injection, turbochargers, electronic hardware, and variable valve timing.

In addition to powering the NH3 Kraken tugboat with green ammonia, Amogy demonstrated this technology in an aerial drone, commercial farm tractor, and semi-truck.