Maintenance & Repair

Latest News

Latest Videos

Podcasts

More News

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

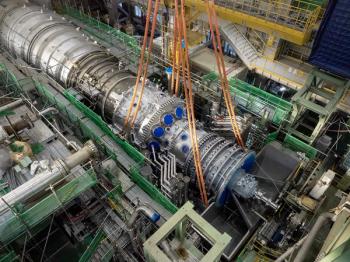

Kozienice is transitioning away from coal-fired power generation, instead using natural gas to generate up to 60% less emissions compared to fossil-fired plants of a similar size.

The magnetic bearing technology reinforces an oil-free design, eliminating the need for a lubrication oil system and preventing wear on sliding parts.

The Turbomachinery News Network, for the week of November 10, 2025, covers news from Arabelle Solutions, Baker Hughes, ExxonMobil, and John Crane.

Performance Plus combines data-driven monitoring, expert consultancy, and hands-on training to help turbomachinery users reduce downtime and boost reliability and long-term resilience.

Following over 250,000 hours of testing, the Jenbacher NX Oil 40 demonstrated significantly reduced soot formation, lower particle counts, and improved dispersion over oil drain intervals.

Per Dora Partners’ Christean Kapp, the Chinese compressor market is acquiring foreign technologies, making improvements, and beginning exports to the Middle East and Asia.

With Antea’s mechanical integrity capabilities, Cordant will link inspection data to asset strategy and performance to optimize maintenance and reduce OPEX costs.

The company will service and maintain multiple units at the Taishan nuclear power plant, in addition to supplying a steam turbine, generator, and controls for the Natrium Wyoming plant.

The Turbomachinery News Network, for the week of November 3, 2025, covers news from Yokogawa Electric, GE Vernova, Everllence, Concepts NREC, and Mitsubishi Heavy Industries.

The new update improves volute modeling with enhanced 3D models and tongue geometries, in addition to expanded leakage path capabilities with a secondary network solver.

When using gear units within turbomachinery trains, operators should consider wear and degradation, torsional problems, lubrication, and more.

By 2030, the Jafurah gas field may produce up to 630,000 barrels of natural gas liquids and condensates, in addition to over 420 million cubic feet of ethane per day.

Since installation, the Fadhili Gas Plant has demonstrated a 10 – 15% reduction in amine and steam usage and an approximately 5% reduction in power usage.

The company’s coiled-tube drilling operations include its CoilTrak bottomhole assembly system and enhanced reservoir analysis driven by the GaffneyCline energy advisory.

The 2026 Handbook includes a comprehensive outlook of the U.S. power industry and gas turbine market, as well as an industry-wide directory and specifications listings.

The newly opened facility is expected to boost aeroderivative repair capabilities and reduce component lead times across Argentina, Brazil, Chile, and Uruguay.

The motor pipeline compressor design eliminates the need for dry gas seals and lubrication systems, leading to higher reliability and minimized lifecycle costs.

This win marks the company’s first overseas export deal for gas turbines, with Doosan Turbomachinery Services performing maintenance at its Houston-based location.

With the energy transition accelerating and much of the existing infrastructure reaching the end of its operational life, modernization has become essential for the gas transmission sector to maintain safety, capacity, and environmental performance. One standout example is the recent Cab Infrastructure Project undertaken by Braden, a global leader in gas turbine auxiliary equipment for Gas Turbine Systems. Tasked with revitalizing a Gas Turbine compressor unit at a critical site in the South of England, Braden delivered a solution that not only extended the unit’s operational life but also prepared it for a cleaner energy future.

Thin-wall casings and shell bodies play a critical role in turbomachinery, but their susceptibility to imperfections and buckling raises leakage and failure risks.

The new infrastructure includes a new power line, main 138-Kv breaker, 100-MVA power transformer, and numerous capacitor banks to allow full-speed, full-load testing.

Using a proprietary mix of sand and other particles, the dust-ingestion testing aims to replicate how parts may withstand flight conditions in harsh operating environments.

The September/October 2025 issue covers steam turbine optimization, a pump-centric conversation with the Hydraulic Institute, hybrid grid technology for stabilization, and much more.

In addition to servicing critical oil and gas safety systems, EthosEnergy’s Approved Repair Facility designation will enable faster turnaround times and localized support.