This partnership follows the commissioning of GAIL's green hydrogen plant, in which Accelera supplied a 10-MW proton exchange membrane electrolyzer system.

This partnership follows the commissioning of GAIL's green hydrogen plant, in which Accelera supplied a 10-MW proton exchange membrane electrolyzer system.

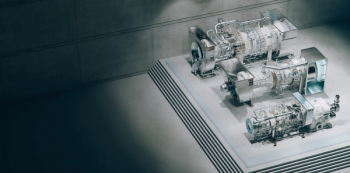

The company will deliver CO2 compression and monitoring technologies for the Sweetwater Carbon Storage Hub and gas turbines for power generation applications.

Bert Warner of the Propane Education & Research Council identifies three growth opportunities for propane: portable power generation, EV charging, and combined heat-and-power.

The company designed and supplied digesters, a prefabricated containerized pump-block system, heating and boiler containers, and a prefabricated factory-tested control container.

Initially, the venture will advance four natural gas, combined-cycle power plant projects totaling over 5 GW in the ERCOT & PJM markets.

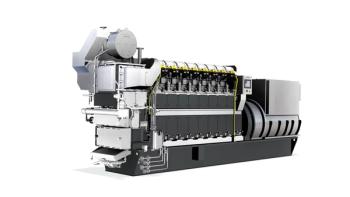

Bobby Noble of EPRI says gas turbines are “well sought after” thanks to data center power demands and shifts in the energy portfolio mix.

The contract’s wider resource opportunity across Kirkuk and the surrounding area is projected to include up to 20 billion barrels of oil equivalent.

The company's solution can capture over 95% of CO2 emissions from post-combustion sources, including gas-fired power plants, boilers, waste-to-energy, and biomass-to-energy sites.

Bert Warner of PERC and Jim Crouse of Capstone discuss propane’s greatest benefits: ease of deployment and transportation infrastructure.

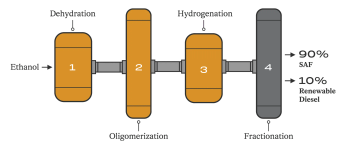

Cosmo Oil will combine its expertise in plant operations, fuel quality control, and logistics with Mitsui's capabilities in ethanol procurement to develop the project.

The IANUS project will also expand research laboratories and develop modular electrolyzers for large-scale, multi-MW industrial applications.

Kevin Lauzze of Sargent & Lundy discusses the rise of carbon-capture pilot projects and how technologies can successfully enter the market.

Kevin Clark of Clarion Events says, "Power generation is having its day ... again," with data centers, onshoring manufacturing, and electrification beefing up demand.

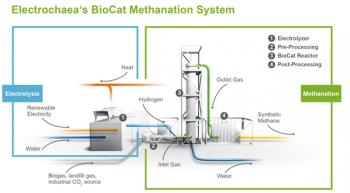

The deployment of Electrochaea´s technology will support Japan’s climate goals to achieve 5% carbon-neutralized gas via the injection of 1% synthetic methane by 2030.

Klaus Payrhuber and Michael Collins of INNIO Jenbacher detail hydrogen engine demonstration projects that may bridge the gap created by renewables.

The port fuel-injection methanol concept makes the 21/31DF-M medium-speed, small-bore engine suitable for genset and diesel-electric propulsion applications.

The test phase will also verify the safety and performance of MITSUI E&S’s ammonia fuel-supply system and peripheral systems.

Jeff Benoit and Bobby Noble discuss the reliability and flexibility of gas turbines and how they satisfy many needs within power generation.

OEMs are using AI- and ML-equipped software and control systems to improve data quality and reliability, automate tasks, monitor assets, assist smaller crews, and make predictive maintenance commonplace.

The Raven Field’s initial phase developed eight subsea wells, located up to 65 km offshore, at water depths ranging from 550 to 700 meters.

The engines and associated cooling systems will be available for purchase by independent OEMs for integration into their own genset designs.

Paul DiMascio of ProEnergy discusses how direct ammonia injection systems simplify NOx and CO removal.

Keynote speakers focused on power consumption and how it will be managed and sustained in the future.

POWERGEN International 2025 spotlights its reoccurring theme: Destination 2050.

INEOS, Royal Wagenborg, and Royal Niestern Sander shipyard will develop a liquefied CO2 carrier, expected to enter service by year-end 2025.