Auxiliaries & Components

Latest News

Latest Videos

More News

The Ansan Smart Hub will be converted into a high-efficiency, eco-friendly power plant capable of accommodating a future fuel conversion from natural gas to hydrogen.

Mechanically sealed pumps are subject to cavitation damage, thermal shock, and more when operating with ammonia, so operators deploy sealless designs to counter corrosive effects.

The natural gas-fed pipeline system will be expanded in Texas, New Mexico, and Arizona, with potential bidders supporting markets in the Desert Southwest.

The Turbomachinery News Network, for the week of September 22, 2025, covers news from Rolls-Royce, Doosan Enerbility, Everllence, and Siemens Energy.

Dr. Marco Ernst of Everllence says that deploying multiple centrifugal compressor trains allows the company to cover compression from capture to offshore transmission.

The plant will capture, purify, and liquefy up to 30,000 tons of CO2 per year, which is then transported via tanker for use in the food industry.

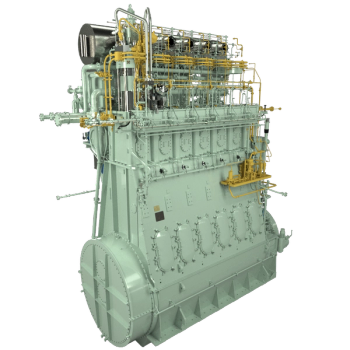

The dual-fuel engines will each supply 18.5 MW of power to build Mauritania’s electricity supply, while the 90-bore ME-LGIM engine successfully burned ethanol at all load points.

With some mechanical and hydraulic modifications, conventional centrifugal pumps can handle supercritical fluids better than most centrifugal compressor designs.

Korea Southern Power and Doosan Enerbility will use Korean-made products in its pumped-storage hydropower projects, strengthening local manufacturing and engineering industries.

The European Union’s Clean Aviation Joint Undertaking aims to transform aviation toward decarbonization, sustainability, and new propulsion concepts.

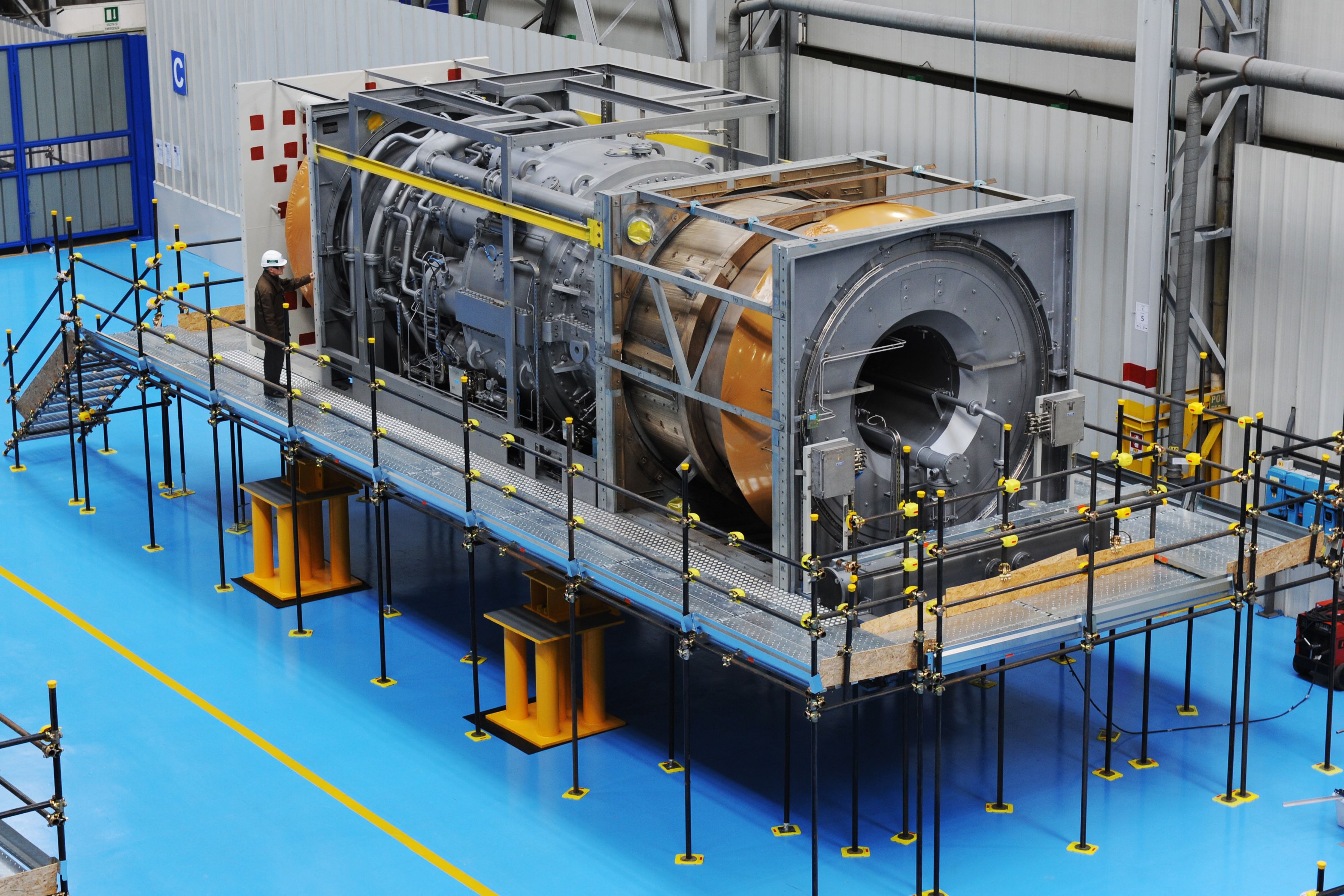

For mechanical testing, the compressor met API’s allowable vibration limit and performance guarantees, validating the design for high-speed applications.

Although hydrogen projects have slowed down since the Trump Administration took office, Siemens Energy will continue technology demonstrations to ensure future-fuel readiness.

While canned motor pumps are suitable for high-pressure ammonia applications, magnetically coupled pumps are typically deployed for higher flow, lower pressure services.

Sealless ammonia pumps ensure safety for nearby personnel by containing leakage and managing the fuel’s inherent toxicity, flammability, and pungent odor.

Facing rising demand, decarbonization targets, and supply chain volatility, John Crane’s Nico Schmaeling urged turbomachinery professionals at the 2025 Turbomachinery & Pump Symposium to address the energy trilemma—security, affordability, and sustainability—through smarter design, efficiency upgrades, and cross-industry collaboration.

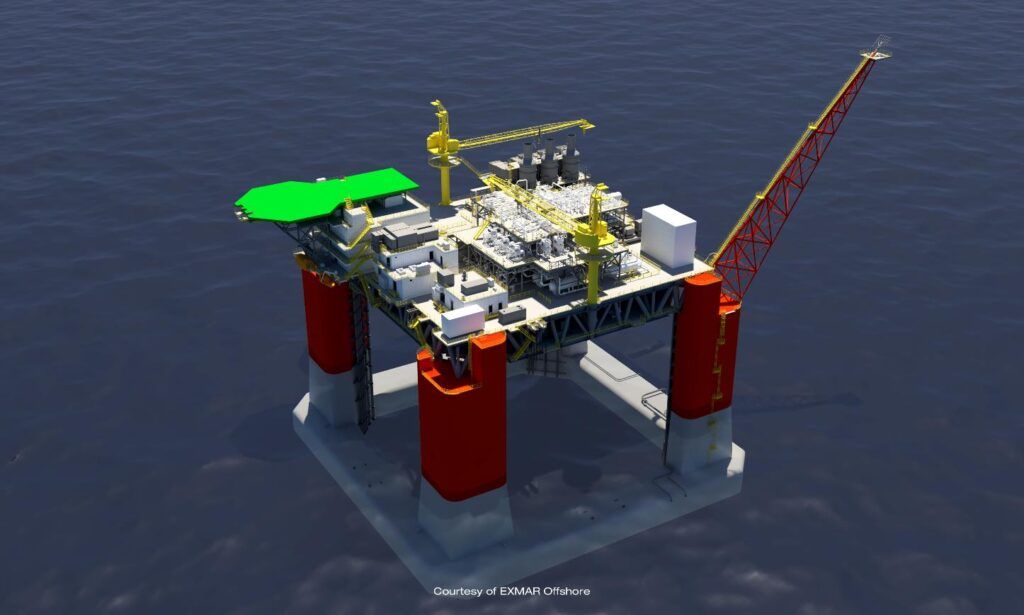

Once operational, the project will capture up to 800,000 tons of CO2 per year for permanent sequestration beneath the North Sea via the Northern Lights facility.

The company’s gas turbine and refrigerant compressor technology supports an additional 6 MTPA of LNG capacity and lower emissions at the Texas-based facility.

The Turbomachinery News Network, for the week of September 8, 2025, covers news from GE Vernova, Mitsubishi Power, Rolls-Royce, and NextDecade.

A major ethane transmission company installed the Type 8628VL seals on inconsistent pump equipment, achieving non-contact performance, low leakage, and zero failures.

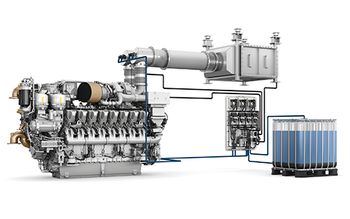

With the new Flex selective catalytic reduction system, ship operators may reduce their physical footprint by up to 42% and cut NOx by 75% compared to IMO II limits.

The new gas turbines, steam turbines, and auxiliary equipment will increase power generation capacity to meet rising industrial and residential electricity demand.

The international consortium partners are progressing on the engine demonstrator, technologies for additive manufacturing, cooling systems, and high-pressure compressor design.

Following Mitsubishi’s large-frame turbine deliveries, the O Mon 4 power plant will raise Petrovietnam’s total installed capacity to over 9,300 MW.

The life-extension project will add up to 30 MW of additional power, with 1.8% efficiency gains, a 5% reduction in CO2 emissions, and improved grid stability.

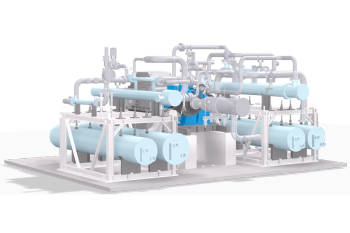

In addition to five centrifugal compressor trains, the supply includes dynamic process simulations and a digital twin with virtual sensors for the integrally geared compressors.