Ontario Power Generation’s Darlington site will host the first small modular reactor constructed in the Western Hemisphere.

Ontario Power Generation’s Darlington site will host the first small modular reactor constructed in the Western Hemisphere.

The Turbomachinery News Network, for the week of May 5, 2025, covers news from Rotating Machinery Services, Rolls-Royce, Ansaldo Energia, and Bosowa Energy Group.

The partnership includes LNG supply-chain integration, FSUs development, natural gas power generation, downstream energy applications, and more.

Bruno Monetti of GE Vernova details how local supply chain investments and strong supplier relationships can overcome market challenges.

The large-scale Asian buyer will obtain 1 MTPA of LNG over a 20-year term from the 9.5 MTPA LNG liquefaction and export facility in Cameron, LA.

Technip Energies’ design includes large-scale offshore platforms, flare platforms, connecting bridges, and related infrastructure.

The upgrades will improve electricity output, response time, fuel efficiency, and more as Michigan enters its summer peak-generation period.

Ansaldo Energia’s MXL3 upgrade lowers emissions by up to 20%, boosts power output and efficiency, and enables 45% hydrogen co-combustion on its GT26 gas turbine.

Supply and faster maintenance intervals are impacting the aeroderivative gas turbine market as OEMs try to keep up with demand.

Doosan and HD Hyundai Marine Engine will develop precision casting manufacturing technology and prototype blade materials for gas turbines.

Fusion Inc. joins RMS’s domestic repair network, offering customers thermal spray coatings, laser cladding, and other critical turbomachinery services.

Turbine Weld Industries will contribute to VSE’s aftermarket position with its repair specifications and technologies for hot-section components.

The new compressor line features improved corrosion resistance, thermal efficiency, and reduced tube blockage.

The Turbomachinery News Network, for the week of April 28, 2025, covers news from GE Vernova, ExxonMobil, Ansaldo Energia, and Woodside Energy.

Louisiana LNG will purchase approximately 640 Bcf of natural gas from bp, the primary natural gas supplier, with deliveries planned for 2029.

Hanwha Aerospace will assemble and test the eight LM500 marine gas turbine engines before installing them on four Korean patrol boats.

The May/June 2025 issue spotlights the gas turbine market, deep-diving into order activity, the impact of surging power demand, and how the industry is responding.

The Louisiana LNG facility is a three-train, 16.5 MTPA development scheduled for first LNG in 2029.

How accurate are advanced computational tools like CFD and FEA? Find out in part II of designing turbomachines with the Myth Busters.

Duke Energy is installing 11 of GE Vernova's 7HA turbines across numerous power projects using current infrastructure and transmission capabilities to satisfy AI-driven demand.

Taurus Energy will be the first to implement the AGP XPAND upgrades, which include improved materials and sealing of advanced gas path components.

Henrik Harksen of MTU Maintenance talks about its new MRO shop that will support a 30% increase in shop visit volumes.

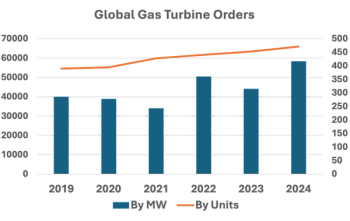

Order activity spiked in 2024, as the gas turbine market was driven by data center development and natural gas and LNG.

Nikon’s research program at the University of Waterloo will combine direct energy deposition and titanium powders to repair damaged or worn aerospace components.

Do engineers overrely on computational tools? The Myth Busters deep dive into engineering tools, such as CFD and FEA, used to design turbomachines.