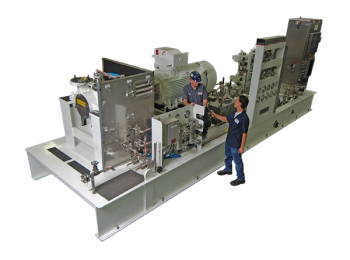

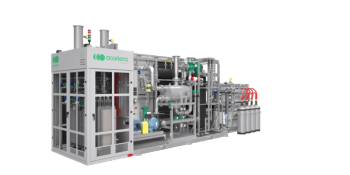

The centrifugal hydrogen compressor uses a newly developed impeller to handle high flow rates, boost hydrogen pressure, and improve liquefaction efficiency.

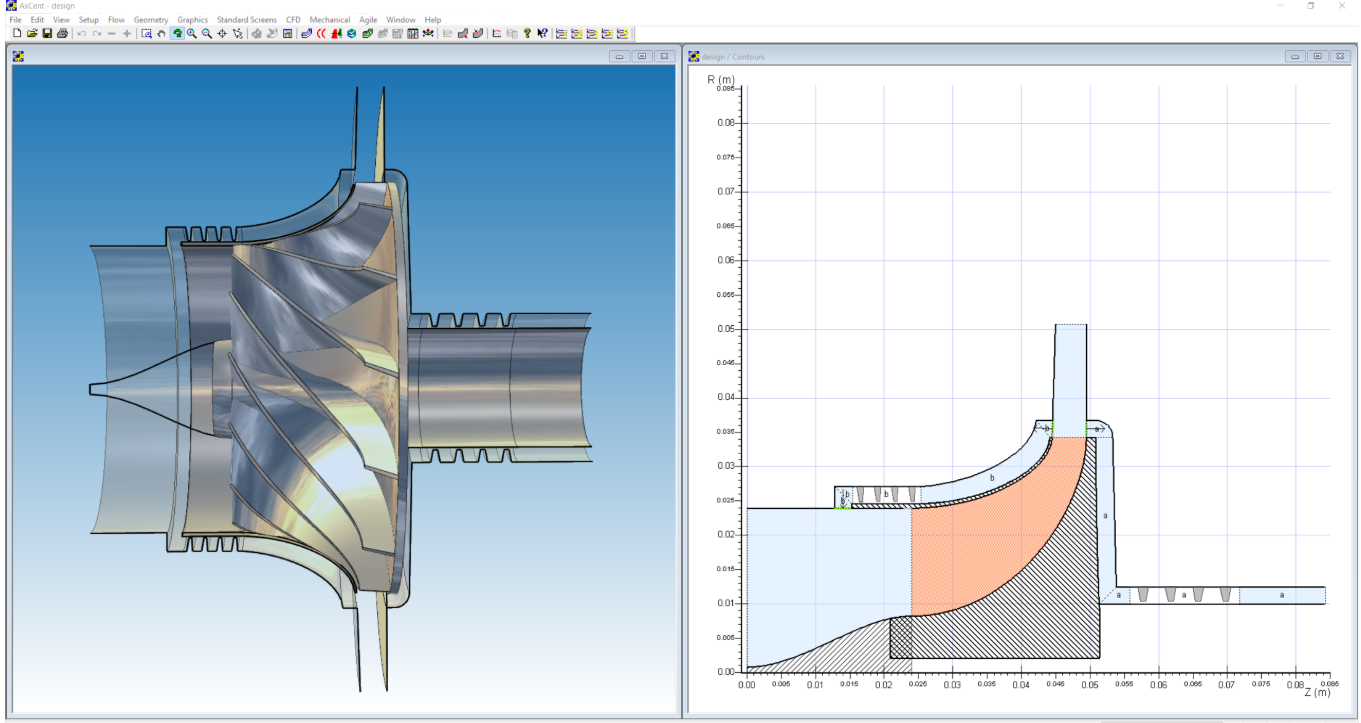

Concepts NREC’s Agile Engineering Design System Gets a Rotordynamic Upgrade

The centrifugal hydrogen compressor uses a newly developed impeller to handle high flow rates, boost hydrogen pressure, and improve liquefaction efficiency.

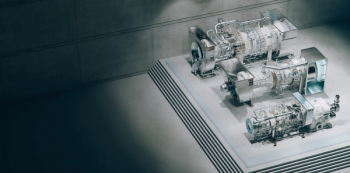

The Turbomachinery Laboratory at Texas A&M researches compressors, turbines, and pumps, fostering collaboration between academia and industry.

Four key distributors will expand their parts, compressors, and additional products and services across Ohio, Pennsylvania, West Virginia, and more.

“Build Baby Build” has brought about the remake of the energy transition to the energy addition.

The March/April issue focuses on maintenance and repair and how data and AI are impacting the field and highlights our latest Turbo Tour.

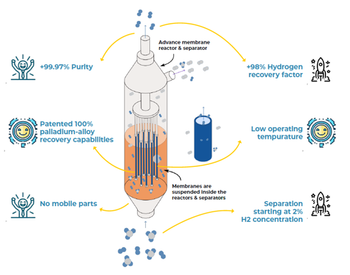

The membrane efficiently separated hydrogen from the natural gas stream, enabling the production of high-purity hydrogen and cleaner streams.

Most transient surge analysis software relies on significant assumptions about one- versus three-dimensional effects and presumes steady-state compressor maps.

Recently, Chart Industries completed the front-end engineering and design for the nitrogen rejection unit and helium plant.

The Phase 1 expansion will increase total treating capacity to 200 MMcf/d, with plans to increase it further to 400 MMcf/d by 2026.

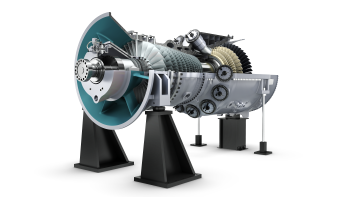

The NovaLT gas turbine will allow data center customers to adapt and meet their specific, reliable, and sustainable power requirements.

Adolfo Delgado of Texas A&M’s Turbomachinery Laboratory says component-level testing and development have significant impacts on the industry as a whole.

Baker Hughes submitted its solution to the Tradewinds Solutions Marketplace and can now develop geothermal plants for baseload power.

The contract represents over 100,000 hours of annual maintenance executed by a 30-person team, so EDF PEI can achieve 95% availability on power assets.

Once NextDecade permits, constructs, and operates Trains 6 through 8, the total liquefaction capacity will increase by approximately 18 MTPA.

The acquisition will expand the range of high-performance components, shorten lead times, and offer greater service flexibility for customers in critical industries.

The Honeywell Forge software platform will enable the digitalization of Sundyne's equipment, improving reliability and predictive maintenance operations.

This partnership follows the commissioning of GAIL's green hydrogen plant, in which Accelera supplied a 10-MW proton exchange membrane electrolyzer system.

The company will deliver CO2 compression and monitoring technologies for the Sweetwater Carbon Storage Hub and gas turbines for power generation applications.

The commissioning of Kuo Kuang 2 replaces older, CO2-intensive plants on the grid, emitting up to 66% less greenhouse gases than coal- or oil-driven power.

Combining 3D laser scanning and generative AI automates inspection processes, enhances service quality, and expedites equipment overhauls.

The company is working with partners to increase the feed-in of renewable electricity for the Friedrichshafen, Augsburg, and Aiken/USA plants and their local grids.

OEMs are using AI- and ML-equipped software and control systems to improve data quality and reliability, automate tasks, monitor assets, assist smaller crews, and make predictive maintenance commonplace.

The Raven Field’s initial phase developed eight subsea wells, located up to 65 km offshore, at water depths ranging from 550 to 700 meters.

Integrating CFD analysis software into blade design software increases time-to-market.

Keynote panelists discuss the latest innovations in gas turbine combustion systems, carbon capture, hydrogen, ammonia, and more.