Hanwha Power Systems offers insights into its supercritical CO2 systems that leverage high energy and dual gas/liquid properties to efficiently drive larger machines.

Ebara Elliott Energy Updates Manufacturing Facility with Compressor, Electrical Equipment Testing

Curtiss-Wright, Sintavia Provide Additively Manufactured Impeller for U.S. Navy Submarine

Hanwha Power Systems offers insights into its supercritical CO2 systems that leverage high energy and dual gas/liquid properties to efficiently drive larger machines.

The Golden Triangle Polymers project will receive three main compressor packages for its ethane cracker operation, auxiliary equipment, three steam turbines, and four centrifugal compressors.

The CO2-based seawater heat pump operates with a wood chip boiler and electric boiler plant to provide heat year-round.

The expansions include six compressor overhaul stations, two drive-through loading bays, an extruder overhaul station, and additional storage and maintenance spaces.

The sCO2 power generation system will be installed at TC Energy’s compressor station in West Virginia, recovering unused waste-heat exhaust from a gas turbine compressor.

Warwood delivers electric motor and gearbox repair, sales, and field services that focus on coal, steel, shale, and industrial customers in the Appalachian region.

The November/December 2024 issue highlights emerging decarbonization efforts that integrate hydrogen, ammonia, and new technologies into increasingly intermittent grids.

Part two of this myth on centrifugal compressor maps delves into the map’s extrema: surge and choke.

A compressor’s seal system is the culprit of most common unscheduled shutdowns.

To capture and reinject natural gas into oil reservoirs, Air Source One uses rotary screw compressors, an integrated heater, and a ventilation system.

United Aerospace Maintenance Co. will fulfill the customers’ CFM LEAP maintenance needs in Europe, the Middle East, and Africa by conducting on-wing-support and near-wing retrofits.

The AI-assisted borescope inspection technology raised model recall rates by 33.6% and increased model precision rates by 13.5% compared to the previous Gas Power-assist model.

Ebara obtained an additional sales base in Uruguay, capitalizing on a growing South American market for pumps in the agricultural, construction, and industrial sectors.

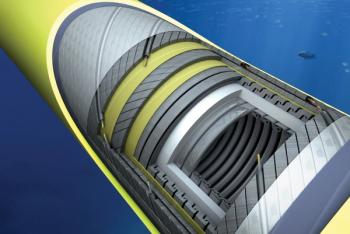

Petrobras signed contracts with Baker Hughes for risers and flowlines for hydrocarbon production and gas and water injection; and support for equipment storage, maintenance, and installation.

Mitsubishi Gas Chemical will receive ~1 mmtpa of methanol from the Mexican production facility, slated to open in 2028 producing green and blue methanol from natural gas with carbon capture.

Peru LNG owns and operates the only LNG export facility in South America, consisting of a natural gas liquefaction plant, pipeline, storage tanks, and additional assets.

TPS 2024 tackled the latest challenges, solutions, and technologies in the turbomachinery industry.

Daniel Tegtmeier of EthosEnergy shares how remote monitoring has grown over the past several years and the advantages and challenges of virtual capabilities.

The Gillis Treating Plant will treat off-spec natural gas with services such as CO2 amine treating, gas dehydration, CO2 compression, and related utility and power systems.

John Bartos, CEO of RMS, says acquiring precision engineering, advanced metrology, and more allows the company to provide end-to-end solutions.

The Emirates Central Cooling Systems Corp. (Empower) will supply chilled water for cooling to residential, commercial, healthcare, educational, and multi-use projects.

The 2025 Handbook includes a comprehensive outlook of the power industry and gas turbine market as well as an industry-wide directory and specifications listings.

Integrating an exhaust gas recirculation system reduces the cost and footprint of a carbon-capture system and lowers operating costs.

Baker Hughes won a contract to supply the deepwater development with its compressor technology to minimize emissions and eliminate routine flaring.

Part one of this two-part myth on a centrifugal compressor map covers the basic physics of the constant speed head-flow performance lines.