Users can transition toward measurement-supported methane accountability, improving operational efficiency and safeguarding their market position.

Dover Broadens Cryogenic Centrifugal Pump Portfolio with Cryo-Mach Acquisition

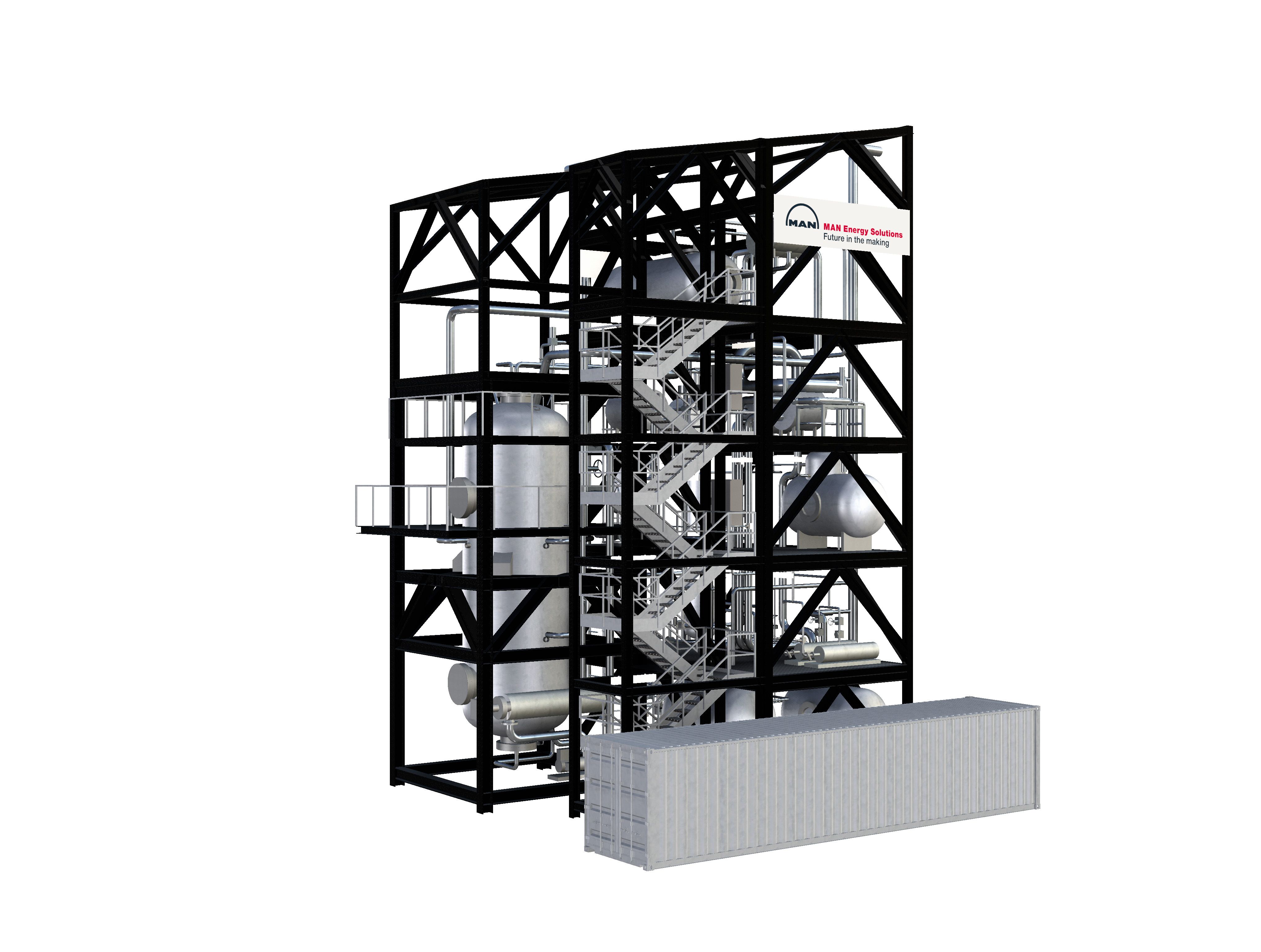

MAN Energy Delivers Methanation Reactor for Tampere Power-to-Gas Project

Users can transition toward measurement-supported methane accountability, improving operational efficiency and safeguarding their market position.

Managers from a gas-treating company investigated the effects of varnish on the vibration of bearing No.2 of a Siemens SGT 600 gas turbine.

This project will enable oil and gas operators, tribes, and other U.S.-based entities to reduce, monitor, measure, and quantify oil and gas methane emissions.

Svante will capture, compress, condition, and liquefy CO2 emissions, and Tenaska will manage CO2 transportation and sequestration.

Brightmark partners with farmers to produce RNG through anaerobic digestion to collect and digest organic waste to extract methane and upgrade it into RNG for use as fuel.

The facility will produce up to 800,000 MTPA of clean ammonia and connect to nearby natural gas and CO2 sequestration infrastructure.

Celeros and Flowserve will develop high-pressure injection packages for ADNOC’s Habshan gas plant, capturing and storing 1.5 million tons of CO2.

GE Vernova’s DLN combustor technology eliminates the use of water and other diluents and improves the combined-cycle heat rate by 4 - 7%.

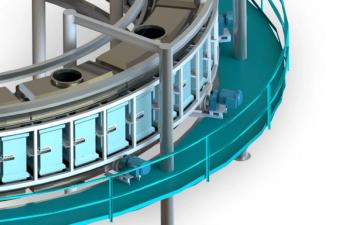

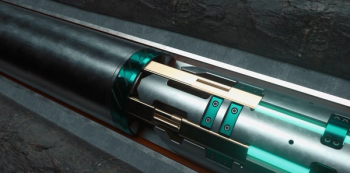

SureCONNECT FE allows operators to implement fiber-optics monitoring, electronic monitoring, and electric intelligent completion systems in land- and sea-based wellbores.

Rotating Machinery Services conducts specialty repair, maintenance, overhaul, and custom manufacturing for critical OEM and non-OEM turbomachinery infrastructure.

The 104-mile, high-pressure gas gathering pipeline connects natural gas supplies from the Williston Basin to high-demand markets in the northern United States.

The turboshaft engines will be built and delivered under a contract with the U.S. Army through the government’s Foreign Military Sales process.

The Whale’s estimated peak production is 100,000 gross boe/d, with up to 15 wells under development and equipped with energy-efficient gas turbines and compression systems.

Global Compression Services issues OEM and aftermarket components and manufactures specialized parts tailored to the natural gas sector.

Ana Amicarella, CEO of EthosEnergy, said One Equity Partners’ expertise in mergers and acquisitions will help expand service offerings and improve operational efficiencies.

The plant has no access to the public grid, so each Rolls-Royce mtu genset supplies 2,500 kW of electric power to manufacture medium-density fiberboard.

Residential and commercial heat pump programs aim to develop pumps that perform at sub-zero temperatures and as emissions-effective rooftop units.

The new power plant replaces the current facility and reduces natural gas consumption by 15%.

The new lubricants and additives include FSE-TurboCool 32 and 46; FSE-TurboCool PG; FSE-TurboCool FG; and FSE-TurboCool CC to minimize downtime and extend lifespan.

The project adds 423,400 Dth/d of fully contracted pipeline capacity, two new all-electric compressor stations, and upgraded metering stations to accommodate demand.

Eight main refrigeration compressors driven by LM6000PF+ gas turbines and eight expander compressors will assist Woodside Energy in executing Phase 1 of Louisiana LNG.

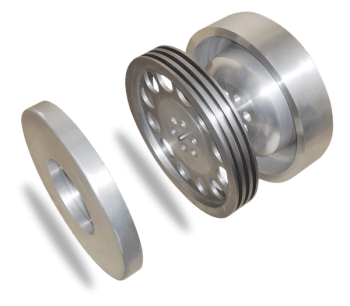

Simplifying, re-configuring, and eliminating certain components can increase a turbomachine’s reliability, efficiency, and safety and, in some cases, reduce costs.

The engines, to be assembled at the ITP Aero Facility and modularized by Rolls-Royce, are scheduled for delivery to the Spanish Air Force in 2029.

With over $80 million currently invested in the Global Repair Service Center, GE Vernova plans to meet regional population growth and power demand by keeping its fleets operational.

Klaus Brun and Rainer Kurz explain root-cause analysis and how it assists operators in diagnosing turbomachinery failures.