Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

Babcock & Wilcox Assesses SolveBright CO2-Capture Tech for Swedish Plant

EthosEnergy Partners with EP Produzione to Retrofit Trapani Thermoelectric Power Plant

Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

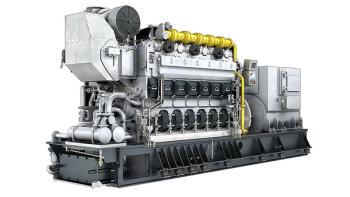

Christian Kunkel of MAN Energy said ammonia integration in four-stroke internal combustion engines is possible with modified injection systems, but its inherent toxicity presents technical challenges for AmmoniaMot 2.

The studies targeted up to 32% by volume hydrogen blending with natural gas and identified modifications to the power generation assets, including exhaust gas recirculation to lower carbon-capture costs.

Ebara obtained an additional sales base in Uruguay, capitalizing on a growing South American market for pumps in the agricultural, construction, and industrial sectors.

With Safety Integrity Level certification, the XMO2pro analyzer is explosion-proof, flame-proof, and weather-proof with a built-in compact display suitable for tight spaces.

Investments include an additional horizontal boring mill, a commutator repair system, and expanding the Wyoming shop’s footprint with a new test stand and 40-ton crane.

The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

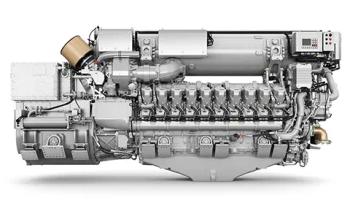

With future submarines expected to require increased electrical power, the mtu charging unit and NautIQ automation system will enable higher power output and integrated control, respectively.

In addition to HA combined-cycle equipment, GE Vernova signed a 12-year service agreement to manage the project lifecycle, training, and maintenance at the Gryfino Dolna Odra plant.

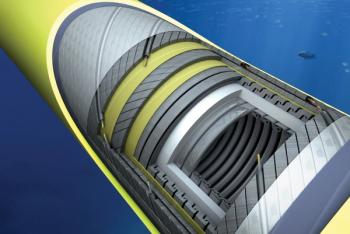

Petrobras signed contracts with Baker Hughes for risers and flowlines for hydrocarbon production and gas and water injection; and support for equipment storage, maintenance, and installation.

In addition to the hydrogen-capable 9HA.01 gas turbine, GE Vernova will supply an STF-A650 steam turbine, W88 generator, and heat recovery steam generator for the upcoming Singapore-based plant.

Peru LNG owns and operates the only LNG export facility in South America, consisting of a natural gas liquefaction plant, pipeline, storage tanks, and additional assets.

Following the licensing agreement, Jiangsu Masada will begin manufacturing MET turbochargers in 2025 with an initial focus on assembly.

Supported by the European Innovation Fund (EIF), ACCSION will receive €220M and, using its Cryocap technology, will capture, purify, and liquefy approximately 95% of the CO2 emitted by the cement kilns at the Denmark plant.

TPS 2024 tackled the latest challenges, solutions, and technologies in the turbomachinery industry.

Koch-Glitsch will deliver proprietary separation equipment for ION’s post-combustion carbon-capture projects, increasing performance while minimizing cost and physical footprint.

The investment will fund additional engine test cells and new equipment and technology, including AI-enabled inspection techniques.

The Gillis Treating Plant will treat off-spec natural gas with services such as CO2 amine treating, gas dehydration, CO2 compression, and related utility and power systems.

The company will design the entire four-stroke, medium-speed ammonia-engine concept for maritime applications, including the exhaust gas after-treatment system.

John Bartos, CEO of RMS, says acquiring precision engineering, advanced metrology, and more allows the company to provide end-to-end solutions.

Tyler Clifford of Siemens Energy speaks on alternative fuels like methanol, gas turbines, 3D printing, and decarbonizing industrial markets.

India’s Missile Vessel (NGMV) will reach a max speed of 35 knots and utilizes the LM2500 marine gas turbine for propulsion power and stealth requirements.

The Emirates Central Cooling Systems Corp. (Empower) will supply chilled water for cooling to residential, commercial, healthcare, educational, and multi-use projects.

The 2025 Handbook includes a comprehensive outlook of the power industry and gas turbine market as well as an industry-wide directory and specifications listings.

Methanol as an alternative fuel can cut CO2 emissions between 10 – 95% depending on how it’s produced.