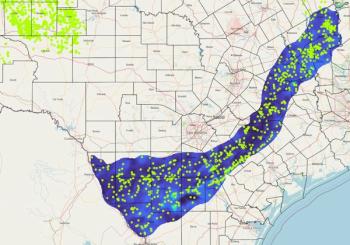

With the largest CO2 pipeline network in the United States, ExxonMobil will leverage its infrastructure for the newly leased 271,000-acre offshore storage site.

With the largest CO2 pipeline network in the United States, ExxonMobil will leverage its infrastructure for the newly leased 271,000-acre offshore storage site.

Phase 1 advanced gas path (AGP) upgrades can increase the Besmaya power plant’s output by 6%, as well as improve fuel consumption and extend asset lifespan.

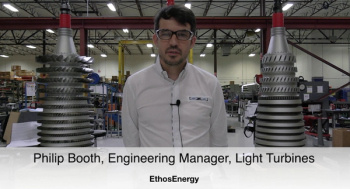

On our Turbo Tour of EthosEnergy, Engineering Manager Philip Booth spoke about the repair, overhaul, and aftermarket markets.

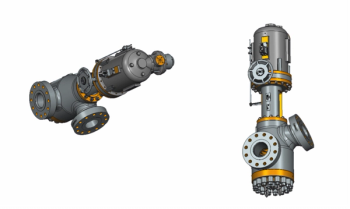

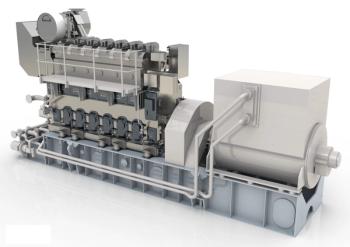

The 10 integrated compressor line (ICL) units will be installed and increase energy capacity at the Margham gas storage facility in Dubai.

The H-class power generation equipment will increase plant efficiency and replace aging conventional assets: three boilers and three steam turbines.

Siemens Energy is developing three technologies—an advanced rotor hydrogen compressor, a Turbo Heater, and a rotating olefins cracker—to drive the energy transition and reduce carbon emissions.

Operated and non-operated interests in the Athabasca Oil Sands Project (AOSP) and Duvernay shale will be sold to Canadian Natural Resources in a $6.5 billion all-cash transaction.

Turbocompressors with side streams are operated with tight tolerances on operational parameters compared to conventional compressors.

Related assets, manufacturing capability, and personnel have been transferred to Honeywell, including the coil-wound heat exchanger manufacturing facility in Port Manatee, FL.

The system will feature power-conversion technologies, including propulsion-load electric motors, E-houses, power electronic motor drives, load banks, transformers, and more.

In this episode of the TurboTime podcast, Daniel Tegtmeier, Director of EthosEnergy’s Performance Center, talks about remote operations and monitoring.

At full capacity, the new gigahub will enable the automated series production of PEM stacks with a potential total electrolysis capacity of more than 5 GW per year.

The company acquired APSCO, a hydraulic and pneumatic provider; Blutek, a compressed air and nitrogen generation solutions designer; and UT Pumps, a screw and plunger pump manufacturer.

Modernization options for ammonia syngas trains can meet a wide range of plant requirements for uptime, efficiency, costs, and footprint.

The first phase capacity of 1.5 million tons of CO2 per year is fully booked, and the joint venture owners are working to further increase the transport and storage capacity.

Marubeni will provide technical and financial assistance for Ozona to identify and acquire pore space, permit sequestration wells, and establish facilities and pipelines in Texas.

Two Arctic offshore patrol ships will be equipped with 6L32/44CR engines, common-rail electronic injection, turbochargers, electronic hardware, and variable valve timing.

In addition to powering the NH3 Kraken tugboat with green ammonia, Amogy demonstrated this technology in an aerial drone, commercial farm tractor, and semi-truck.

Unlike typical geothermal systems, geopressured geothermal systems (GGS) repurpose fracking technology to extract thermal energy from miles below the Earth’s surface.

The VS6 sensor features a cold-start suppression function, a protection class of IP67, and is compatible with most Eaton hydraulic filtration systems.

The agreement reorganizes the cooperation, accelerates processes, simplifies procedures, and defines common standards for yacht engines and propulsion systems overhauls.

The retrofit project will reduce the FSRU’s environmental footprint and carbon emissions by reliquefying boil-off gas and returning it to the cargo tanks.

The company will supply and commission the power conditioning systems, power plant controller SCADA systems, and capacitor bank/harmonic filter.

The dual-fuel to spark gas conversion project will modify Chevron’s LNG carrier engines to use spark ignition versus diesel pilot fuel to initiate combustion.

Ammonia-cracking technology uses catalyst materials to crack ammonia into hydrogen and nitrogen at lower reaction temperatures, reducing heating and maintenance requirements.