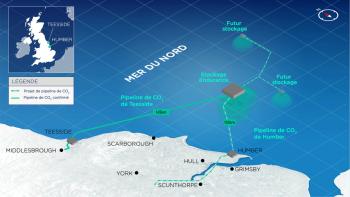

TechnipFMC will deliver and install an all-electric subsea system comprised of trees, manifolds, umbilicals, and infield flowlines to allow CO2 transport over long distances.

New Era Helium, Sharon AI Sign Binding Letter to Develop Energy Data Center in Permian Basin

Baker Hughes, UC Berkeley Form Institute for Decarbonization Materials

TechnipFMC will deliver and install an all-electric subsea system comprised of trees, manifolds, umbilicals, and infield flowlines to allow CO2 transport over long distances.

The supply scope for bp’s enhanced gas recovery and carbon-capture project includes three integrally geared CO2 compressors equipped with an electric motor and variable frequency drive starter.

Jeremee Wetherby, GE Vernova’s Carbon Solutions Leader, said reintroducing part of the exhaust flow back into the gas turbine inlet reduces a carbon-capture plant’s cost and footprint.

Air Liquide will build a hydrogen liquefier and retrofit a hydrogen production unit to use renewable ammonia as feedstock instead of natural gas.

A 35-MW steam pump system at Vicinity’s Kendall Station will use thermal energy from the Charles River to produce high-pressure steam and lower fossil fuel emissions.

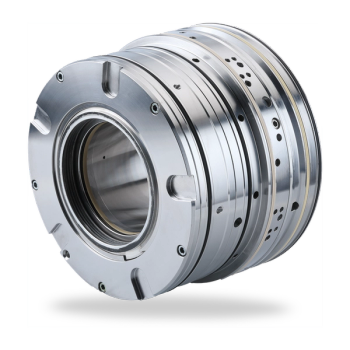

EthosEnergy will join its seal system design, project management, and compressor maintenance with EagleBurgmann’s industrial sealing technology to support customer needs.

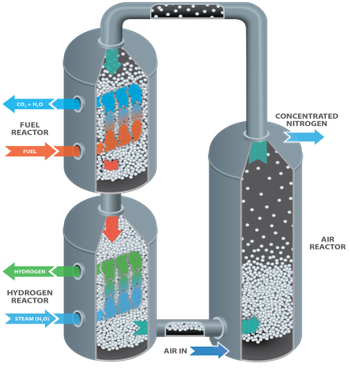

Babcock & Wilcox will use the funding to install chemical looping technology at a low-carbon hydrogen production facility powered by coal and biomass.

The Model LPCMN neutralizes process gases by reducing byproduct adhesion and NOx/COx emissions and offers a compact design, hydrogen fuel options, and high airflow capacity.

The future of hydrogen in power generation depends on the successful integration of technology, infrastructure, and regulatory measures.

The 138-Kv breaker and numerous capacitor banks will regulate voltage dips and swells to protect customer and company equipment during tests up to 100 MW.

Unit 4 will feature fast-start, simple-cycle capabilities and the largest selective catalytic reduction system to reduce emissions and transition away from coal-fired power.

These generators were largely deployed at data centers and commercial real estate developments across Europe, and AVK obtained orders for 120 additional units in 2025.

The Brevik plant, starting operation in 2025, is part of the Longship project—a complete value chain for the capture, transport, and storage of industrial CO2 emissions.

MAN Energy Solutions will provide eight 18V51/60 engines and its after-sales brand will provide spare parts, technical services, and more over 25 years.

Hanwha Power Systems offers insights into its supercritical CO2 systems that leverage high energy and dual gas/liquid properties to efficiently drive larger machines.

The partnership explores deeper geothermal energy sources to lower the plant’s fossil fuel consumption, greenhouse gas (GHG) emissions, and cost compared to traditional geothermal.

The Golden Triangle Polymers project will receive three main compressor packages for its ethane cracker operation, auxiliary equipment, three steam turbines, and four centrifugal compressors.

The CO2-based seawater heat pump operates with a wood chip boiler and electric boiler plant to provide heat year-round.

EthosEnergy’s turbine workshop and Performance Center work hand-in-hand to maintain operators’ turbine equipment and provide remote operations and monitoring.

Dominion Energy is updating the South Carolina-based hydro plant to boost its longevity and performance and better maintain water quality.

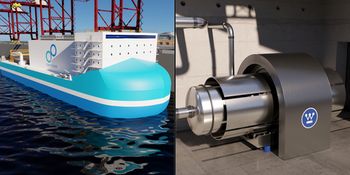

In addition to integrating the eVinci microreactor in modular nuclear plants, Westinghouse and CORE POWER will develop a regulatory pathway to license its floating nuclear power plant design.

The planned 515-MW power plant project will increase Ghana’s thermal generation capacity by over 7%.

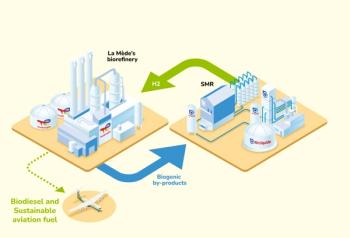

The production unit generates hydrogen using recycled biogenic by-products, which is then fed back into TotalEnergies’ biorefinery to produce biofuels and sustainable aviation fuels.

GridOS orchestration software will help Tensio AS and Linea AS manage energy demands with increased visibility, accelerated decision-making, and built-in security.

When deciding to refurbish or renew, gas turbine plant owners have to weigh engineering and economic factors, including the turbine’s footprint.