Power Generation

Latest News

Latest Videos

Shorts

Podcasts

More News

The compressor trains will perform two process duties—flash-gas compression and high-pressure gas injection—maintaining maximum production in Brazil’s Orca field.

The M701 JAC gas turbine features a flexible operating profile and hydrogen co-firing capability, playing a critical role in stabilizing Qatar’s electricity power grid.

Each half-speed steam turbine, featuring improved cycle efficiency, will be coupled to a hydrogen and water-cooled GIGATOP 4-pole generator synchronized to the 50-Hz Polish grid.

Once operational, the combined-cycle facility will support long-term, system-wide load growth for homes, businesses, and existing industries across Monroe County, GA.

The acquisition provides MIRATECH with increased catalyst production capacity, supporting growth across power generation, gas compression, and industrial/OEM applications.

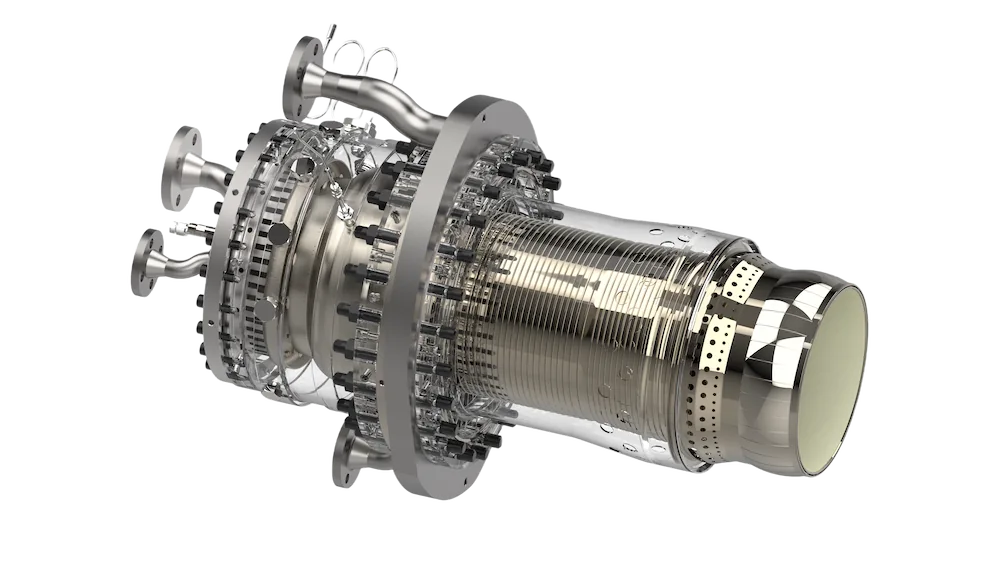

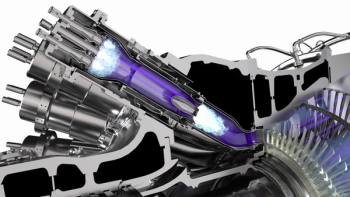

The FLEX4H2 technology uses the company’s Constant Pressure Sequential Combustion system, which burns fuel across two stages and allows independent control, lower emissions, and more.

Electrolyzer-derived green hydrogen will be stored and, when demand is highest, used in a combustion turbine equipped with GE Vernova’s hydrogen co-firing technology.

Additionally, Glenfarne and Donlin will jointly establish a method to develop and construct an approximately 315-mile-long natural gas pipeline from southcentral to southwest Alaska.

The Applied Digital AI Factory project uses a proven plant configuration: A gas-fired boiler generates heat and steam to drive the turbines, producing reliable and dispatchable energy.

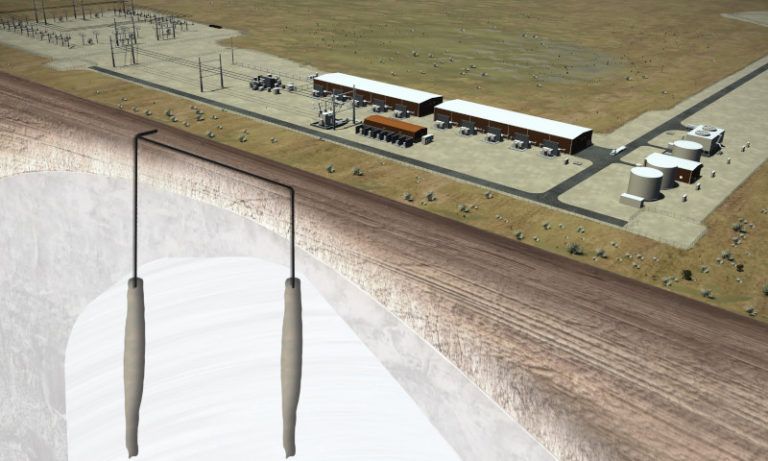

The system’s combined heat and power configuration supports a pyrolysis thermochemical reaction, which converts swine waste into biogas in a closed-loop design.

The acquisition broadens Encore Oilfield Services’ physical footprint with two 80-ton overhead cranes, 70-foot eave heights, and 103,000-square-feet of manufacturing space.

Firm transportation commitments support development of the 36-inch pipeline project aimed at meeting growing power, data center, and industrial demand in the state.

The 40,000-cubic-meter vessel will support a government-backed demonstration aimed at commercializing the global transport of liquefied hydrogen by 2030.

The MK2 project will convert Golar’s LNG tanker—Fuji LNG—into a floating LNG vessel with an expected annual production capacity of 3.5 million tons.

This project accelerates Vietnam’s transition to natural gas-based power generation, which may produce up to 60% less carbon emissions than coal-fired plants of a similar size/power output.

As global demand for lower carbon ammonia increases, the soon-to-be-operational Beaumont New Ammonia facility may approximately double ammonia exports from the United States.

LNG will be supplied from Woodside’s under-construction Louisiana LNG project, bolstering the Turkey-U.S. relationship focused on energy security and economic growth.

Functional testing validated the system’s ability to process the high volumes of operational data generated by progressively larger and higher performance gas turbines.

Hydrogen is gaining traction as the turbomachinery industry balances near-term emissions reductions with long-term fuel flexibility amid evolving regulatory and infrastructure conditions.

Rising electricity demand from data centers and AI is driving renewed investment in gas turbines in 2025, as utilities and operators seek fast, reliable power solutions amid grid constraints.

In addition to delivering centrifugal compressors and LM9000 aeroderivative gas turbines, the full scope includes commissioning services, spares and warranties, and full string tests.

The Qatar Facility E Independent Water and Power Production facility includes a 2,400-MW gas-fired, combined-cycle power plant approximately 10 km southeast of Doha.

Increasing pipeline capacity will satisfy demand growth in the Desert Southwest region, which includes initiatives to retire and/or convert coal-fired plants to natural gas usage.

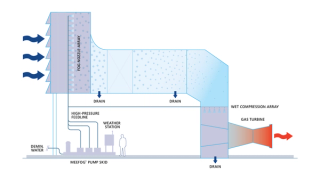

The wet gas scrubbing system features high SO2-removal efficiency, low-pressure operation, reduced energy consumption, and accommodates site layouts with customizable designs.

The GT26 gas turbine will aid Hungary’s decarbonization and power supply initiatives by delivering lower CO2 emissions, hydrogen-ready capabilities, faster load ramping, and more.