The LM6000 gas turbine units feature a newly designed fuel nozzle, optimized water injection schedules, advanced control modifications, and safety features.

The LM6000 gas turbine units feature a newly designed fuel nozzle, optimized water injection schedules, advanced control modifications, and safety features.

GE Vernova will acquire all heavy-duty gas turbine combustion assets from Woodward’s Greenville site after the transaction closes in early 2025.

American Electric Power will install 100 MW of Bloom fuel cells at data centers to help meet increasing AI load and subsequent power demand.

Babcock & Wilcox Thermal will design and install a new natural gas system, air systems, and additional equipment to convert the plant’s two coal-fired boilers.

EcoDataCenter in Falun, Sweden, switched from diesel to HVO to power the 32 mtu backup power generator systems—16 more Rolls-Royce gensets are on the way.

Ohmium, JNCASR, and others are generating green methanol by combining CO2 captured from the Singareni Thermal Power Plant and green hydrogen.

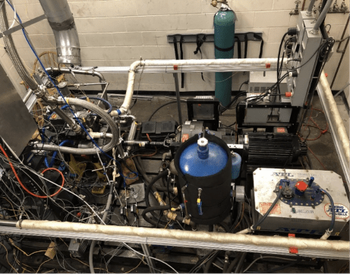

In addition to partnerships with biogas suppliers, methanol offtakers, and technology contributors, Emvolon obtained a $2.3 million technology grant from the Department of Energy.

After a successful demo using multiple fuel types, 2024 KARNO generators will service early adopters in EV charging, data centers, waste-gas utilization, and marine power.

The SolveBright scrubbing system—to be installed at Mälarenergi AB’s waste-to-energy plant—is a post-combustion carbon-capture technology that absorbs CO2 from flue gas.

ETN Global takes a deep dive into decentralized energy systems—advantages such as modularity, roadblocks for integration, and the future of power demand—and the role of gas turbines in a decarbonized future.

The contracts open the door for lower-carbon chemicals exports and the development of storage facilities, tank-to-jetty pipelines, inter-site pipelines, and liquid product storage.

EthosEnergy will replace exhaust systems and additional auxiliary equipment on Trapani Unit 1 at the historic Sicilian plant.

In this episode of the TurboTime podcast, Myth Buster Klaus Brun and Rainer Kurz discuss ammonia.

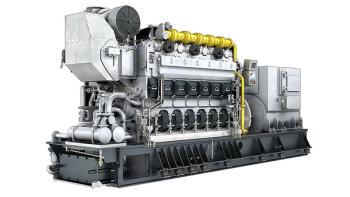

The generator sets will be deployed at five distributed energy sites across Alberta, providing power to the grid during times of peak electrical demand.

Jeremee Wetherby, the Carbon Solutions Director at GE Vernova, offers deeper insights into the benefits of retrofitting carbon-capture systems with an exhaust gas recirculation system.

HD Hyundai Infracore, SK Innovation, and Amogy will explore the long-term commercial viability of their combined ammonia-to-power generation system.

GE Vernova signed a maintenance contract and installed two 7HA.02 gas turbines, one STF-D600 steam turbine, two heat recovery steam generators, and three H65 generators.

Under the joint venture, GLJ will provide consulting services, resource evaluation, and emissions management, and Energy Fuse will contribute its experience in geoscience and engineering.

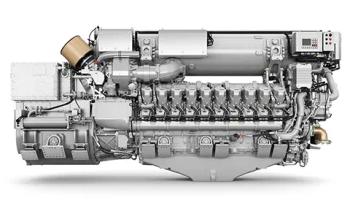

Christian Kunkel of MAN Energy said ammonia integration in four-stroke internal combustion engines is possible with modified injection systems, but its inherent toxicity presents technical challenges for AmmoniaMot 2.

The studies targeted up to 32% by volume hydrogen blending with natural gas and identified modifications to the power generation assets, including exhaust gas recirculation to lower carbon-capture costs.

The gas turbine market is stable and will remain so among factors such as hydrogen, digitalization, and renewable energy.

The company will upgrade the steam turbine and related equipment for Unit 3 at the Darajat Geothermal Power Plant in Java.

With future submarines expected to require increased electrical power, the mtu charging unit and NautIQ automation system will enable higher power output and integrated control, respectively.

The DCFlex initiative will conduct real-world flexibility demonstrations across data centers and electricity markets to streamline grid integration and manage growing electricity demand.

In addition to HA combined-cycle equipment, GE Vernova signed a 12-year service agreement to manage the project lifecycle, training, and maintenance at the Gryfino Dolna Odra plant.