The electrolysis system deploys proton exchange membrane (PEM) technology, which uses electricity to split water into its components: hydrogen and oxygen.

The electrolysis system deploys proton exchange membrane (PEM) technology, which uses electricity to split water into its components: hydrogen and oxygen.

The Turkish Naval Forces, as part of its MILGEM project, will install LM2500 engines on its Ada-, Barbaros-, and Gabya-class frigates and corvettes.

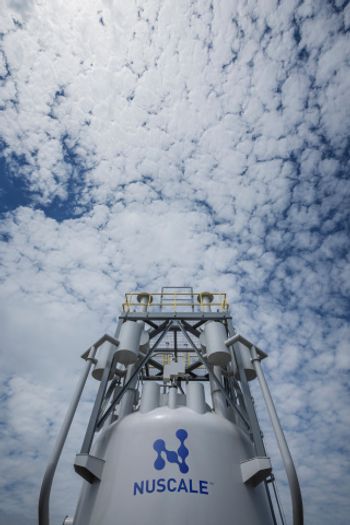

The small modular reactor (SMR) plant will help RoPower Nuclear generate carbon-free power and enhance energy security in Romania.

In addition to the dual-fuel methanol upgrade, the engines will achieve higher efficiency during diesel operation and feature control and safety systems.

In addition to an improved flying range and reduced noise, the Trent XWB-84 engine has a 15% fuel-consumption advantage over first-generation Trent units.

Hydropower’s continued use as a renewable energy source requires complex hydro turbines and other rotating machines to electrify many regions worldwide.

The KARNO generator can use various fuels, including hydrogen, natural gas, biogas, and propane, utilizing a linear architecture to produce electricity with lower maintenance costs.

Approximately $100 million will be invested in the Yazoo City Complex to build a CO2 dehydration and compression unit, complementing its ammonia production process.

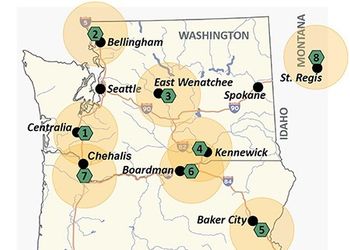

The Pacific Northwest Hydrogen Association (PNWH2) will have eight nodes across Washington, Oregon, and Montana, leveraging technology and renewable energy to decarbonize the industry.

The company’s methane pyrolysis method generates clean hydrogen at point-of-use, eliminating hydrogen transportation and CO2 storage to optimize industrial decarbonization.

In a series of recent aviation deals, Rolls-Royce agreed to deliver 14 Trent 7000 aircraft engines and signed TotalCare and SelectCare agreements with JSX and Vietjet.

Rolls-Royce’s micro-reactor can meet the power requirements to enable long-term exploration and scientific efforts on the Moon and in space.

Nuclear energy, together with renewables and green gas, will establish an energy transition relying on baseload and flexible energy sources at fixed costs.

Testing will demonstrate the technology integration required for 100% hydrogen fuel operation on Rolls-Royce’s modified Pearl 15 engine.

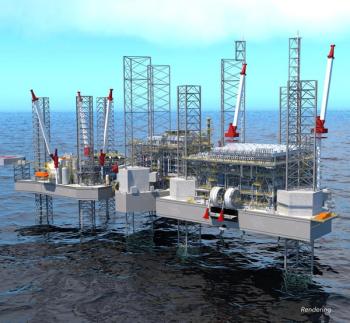

Fast LNG has a production capacity of 1.4 MTPA and will supply low-cost, clean LNG for New Fortress Energy’s downstream terminal customers.

Air Products Qudra’s Blue Hydrogen Industrial Gases Co. (BHIG) generates low-carbon hydrogen while capturing and storing CO2 emissions.

ETN Global’s Scientific Officer, Giuseppe Tilocca, talks about the association’s recent report on decentralized energy systems—their advantages and challenges, trends, and where and how gas turbines fit in.

Cryocap LQ technology is compact and uses a chemical-free, non-flammable process, enabling heat recovery and reuse to supply the district heating network.

The Danish heat pump plant will use four oil-free, hermetically sealed HOFIM motor-compressor units without dry gas seal and lube oil systems.

Combined-cycle power plants equipped with HA-class gas turbines produce approximately 50-60% less CO2 than similarly sized coal-fired plants.

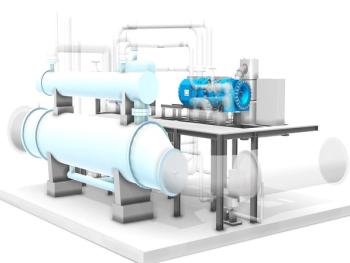

An inside look at turbomachinery in a geothermal plant, how these plants are designed, recent advancements, and how geothermal can help decarbonize the energy landscape.

GE Vernova is delivering synchronous condensers and substations for energy security as more renewables are added to the grid.

The company’s water removal and carbon-capture system is suitable for mobile applications and can be retrofitted onto currently operating power plants.

The first installation of 100% hydrogen-powered mtu 4000 FNER/FV engines is planned for early 2025 at two combined-heat-and-power (CHP) plants for the Enerport II lighthouse project.

Klaus Brun and Rainer Kurz dial into energy storage and transport—why they are necessary, how turbomachinery fits into these processes, and more.