Software & Controls

Latest News

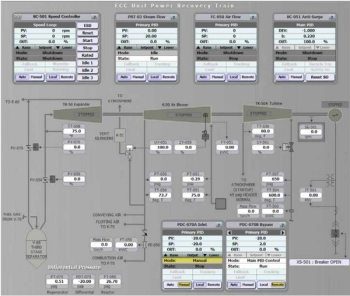

Operation of an integrated control system.

ESC Spectrum has acquired Monitoring Solutions

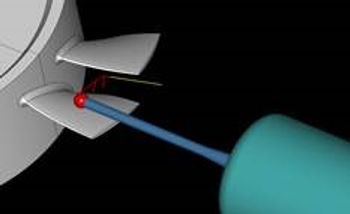

John Crane Sense Turbo is a dry gas seal digital diagnostics solution.

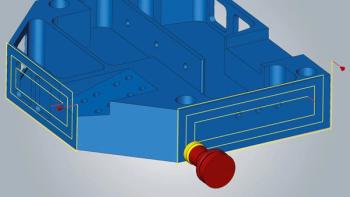

New capabilities, enhancements offered for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

The program will train the next generation of cyber defenders to protect critical infrastructure.

John Crane Sense Turbo digitally monitors the health of dry gas seals.

The company will upgrade the plant’s controls software.

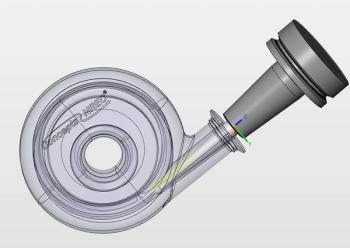

Concepts NREC released the latest version of its Agile Engineering Design System

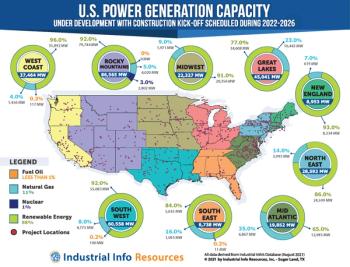

The Biden Administration stresses new-build renewables, but rising gas prices gave new life to coal-fired generators.

In the past, many of these components were only manufacturable as castings.

Manufacturer Schoeller Bleckmann Oilfield Technology purchased an end-to-end AM solution from Velo3D.

Manufacturers are leveraging AR/VR for training, maintenance, design, and production.

Baker Hughes has entered into a multi-year commercial alliance with machine health solution provider Augury.

Digital nameplate, information on coupling filling, operating manuals, tutorials, troubleshooting, Webshop and other services in a user-friendly format on smartphones and tablets.

Elliott Group has released a new turbine wireless sensor specifically designed for Elliott single-stage (YR) steam turbines.

ABB’s Genix Datalyzer is a cloud-based data analytics solution for fleet-wide management and optimization of emissions monitoring equipment.

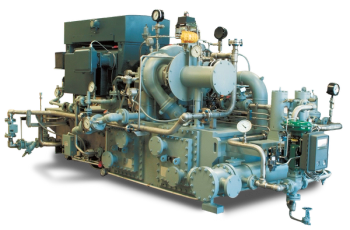

Oil-free air and gas compressors.

The system is compliant to API 670 and meets IEC 61508 up to SIL-3 standards.

The ROC provides IPSC clients truly remote operation, monitoring and start/stop control of existing simple cycle gas turbine peaking projects.